| About Us | Contact Us | Contact Database | Support Us |

- MANUAL-

3.1.3.Solar

Cookers

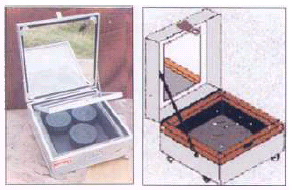

Solar cooker is one of the early devices

developed. A box type solar cooker consisted of an insulated box with

a glass cover

and a top lid, which has a mirror on its inner side to reflect sunlight

into the box when the lid is kept open. The inner part of the box is

painted black. Usually 4 black painted vessels are placed inside the

box along with the material to be cooked. The temperature of the blackened

plate inside the box increases and it can heat up the space inside to

140°C. The cooking time is about 1½ hour to 3 hours depending

on the items being cooked and the intensity of solar radiation. Since

the cooking inside cooker is slow, the food cooked in it retains the

nutrients better than that cooked in the conventional devices. Besides

cooking the meals, the solar cooker can be used to prepare simple cakes

and to roast groundnut, cashew nuts, ‘papads’ and dried grapes,

etc. It, however, cannot be used for preparing ‘chapatties’ or

for frying purposes. A normal box cooker of 0.6m x 0.6m size having a

weight of around 12 kg is capable of cooking 2 kg of food at a time,

and it can save 3-4 LPG cylinders a year if used regularly.

Sun provides hot meals to 1000 devotees every day Eco Centre ICNEER has installed a community

solar cooker in the premises of World Renewal Spiritual Trust

at Mount Abu

in Rajasthan,

India. Twenty-four parabolic

dishes in two parallel rows with the dishes facing each other converge

(direct in a small area) the Sun’s rays onto water bearing pipes for producing

600 kg of steam at 200 °C at 16-20 bar. This steam passes through the

kitchen where it is used to cook between 160-2000 meals each day. Mount

Abu project

is unique in the sense that it cooks meals for 1000 people at a time. Overall

cost

of the cooker was US $ 30,000. |

Various types of solar cookers such as dish solar cookers to prepare food for 10-15 people outside the kitchen, indoor type solar cooker to cook food for around 50 people and solar steam cooking systems to cook food for 1000 people, are being installed in community kitchens of roadside dhabas (restaurants), ashrams, boarding schools, religious places. It uses a lens or a reflector suitably designed to concentrate the solar radiation over a small area. This cooker is able to provide higher temperatures on its absorbing surface when suitably designed.

A community cooker and a dish solar cooker when used regularly can save 35 and 10 LPG cylinders per year, respectively. Seeing the performance of the world’s largest solar steam cooking system at Taleti, Mount Abu, installed in 1999–2000 for 10,000 people, a solar steam cooking system based on similar technology is now operating in several institutions in India.

3.1.3.1 Box Type Solar Cooker

Important

parts of a solar cooker include the outer box with thermal insulator,

inner cooking box or tray, the double glass lid, mirror and

cooking containers. The outer box is generally made of GI, aluminum sheet

or fibre reinforced plastic. Inner cooking box or tray is made up of

aluminum sheet coated with black paint to absorb solar radiation and

to transfer the heat to the cooking pots. Cooking tray is covered with

a double glass lid in which two glass sheets are spaced at about 20 mm

to capture air. It acts as insulator and prevents escape of heat from

the inside. The space between the outer box and inner tray including

bottom of the tray is packed with insulating material such as glass wool

pads to reduce heat losses from the cooker. In addition to above, the

cooker is fitted with a mirror to increase the radiation input on the

absorbing space.

Important

parts of a solar cooker include the outer box with thermal insulator,

inner cooking box or tray, the double glass lid, mirror and

cooking containers. The outer box is generally made of GI, aluminum sheet

or fibre reinforced plastic. Inner cooking box or tray is made up of

aluminum sheet coated with black paint to absorb solar radiation and

to transfer the heat to the cooking pots. Cooking tray is covered with

a double glass lid in which two glass sheets are spaced at about 20 mm

to capture air. It acts as insulator and prevents escape of heat from

the inside. The space between the outer box and inner tray including

bottom of the tray is packed with insulating material such as glass wool

pads to reduce heat losses from the cooker. In addition to above, the

cooker is fitted with a mirror to increase the radiation input on the

absorbing space.

This radiation is in addition to the radiation entering

the box directly and helps to quicken the cooking process by raising

inside temperature of the cooker. The cooking containers (with cover)

are generally made of aluminum and painted black on the outer surface

so that they also absorb solar radiation directly. A large number of

items such as pulses, rice, kheer (rice pudding), khichri (mixture of

pulse and rice), vegetables, meat, fish, etc. can be cooked in the solar

cooker.

The time taken to cook depends upon type of food, angle of the

sun and solar intensity.

3.1.3.2 Solar Baking Unit

Solar baking unit is a scaled up version of double reflector box type

solar cooler. It is designed to generate higher stagnant temperatures

required for baking.

Solar baking unit is a scaled up version of double reflector box type

solar cooler. It is designed to generate higher stagnant temperatures

required for baking.

In order to increase the solar radiation entering the hot box, additional reflectors have been incorporated to reduce the cooking time. In this cooker, twin reflector mirrors (unbreakable acrylic mirror) are fixed. It is effective in central and north India especially in winter season. It is useful for cooking food and baking. As compared to box solar cooker with one mirror, the twin reflector solar baking unit maintains 25 to 30°C temperature. It saves 20% and 12-16% of time, respectively, spent in cooking food during winter and other months. It has thermostat controlled electrical back up of 1 kW to enable proper baking continued even when sudden clouds appear in sky. It is also suitable as a community cooker for up to 10 persons.

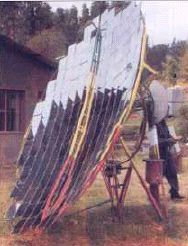

3.1.3.3 Community Solar Cooker

Community Solar Cooker (Rotating Disc Type) works on the principle of

solar energy concentration using a Reflecting Parabolic Solar Concentrator.

It consists of 7-m2 parabolic solar concentrator. Solar Concentrating

Disc or Primary Reflector) is used for concentrating solar radiation

on a focal area where cooking vessel is placed. With the help of simple

automatic mechanical tracking system the solar disc rotates with the

movement of Sun to give continuous and accurate solar energy concentration.

This mechanical device is made up of a simple clock mechanism with

chain and gear arrangement to provide regulated tracking motion to

follow the path of the Sun throughout the day. It works for 6–8

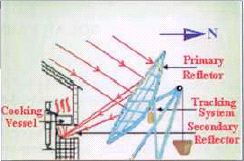

hours in a day. The Secondary Reflector is provided in the north-facing

wall of the kitchen or cooking place just below the cooking vessel.

This reflector receives the concentrated solar radiation and reflects

it on to the bottom of the cooking vessel as shown in the figure. The

Solar Cooker is installed in the open shadow-free area or on terrace

tops facing the South. The reflection of the disc falls on a secondary

reflector housed in an opening in the North kitchen wall. The secondary

reflector further reflects radiation on to the cooking vessel. The

Solar Disc is installed in an open area- terrace or courtyard- facing

the South. The cooker is very simple to operate and easy to maintain.

Daily in the morning, the disc is manually oriented so as to face the

morning sun. Daily orientation action winds the clock mechanism to

work throughout the day and the disc starts rotating in direction of

the Sun guided by Sundial. The Cooker begins to work automatically

as the concentrated solar energy is directed to the cooking vessel.

Yet, the seasonal orientation (adjustment) of the disc is required

to be done once in six months due to shift in Sun's position with respect

to the Earth axis.

3.1.3.4 Community Solar Cooker (Scheffler)

The solar cooker developed by Mr. W. Scheffler, ULOG Group of Switzerland,

has the advantage of cooking food inside the kitchen itself. This is

the latest among community solar cooker designs. Its special features

are as follows:

-

A parabolic dish that reflects sunlight into the kitchen and then onto

a secondary reflector

located below specially designed cooker.

- The cooker's temperature

can be regulated as easily as in conventional

cooking.

- It can be used to boil,

fry and bake.

- It can be used to boil,

fry and bake.

- Unlike other parabolic dishes, this one is flexible with a curvature that can be adjusted seasonally.

- Maximum temperature it creates is 450 °C.

- It has cooking capacity of 70–80 meals per day requiring 1–12 hours to prepare each dish.