| About Us | Contact Us | Contact Database | Support Us |

- MANUAL-

3.3

Other Devices

In addition

to the cooking, mechanical and electrical devices there are other

mixed type of devices that tap the renewable energy and serve

different purposes of the farmers and rural populations.

3.3.1 Drying

Open sun drying of various agricultural produce is the most

common application of solar energy. With the objective of increasing

drying rate and improving quality of the produce natural convection

and forced convection type solar dryers have been developed

for

various commodities. The movement of air in the forced convection

solar dryer is through a power blower, whereas in natural convection

solar dryer air moves through the produce due to natural thermal

gradient.

3.3.1.1 Domestic Solar Dryer

This is a small dryer meant for domestic uses of drying small quantities

of products such as vegetables, fruits, condiments and spices. In this

dryer, the convection of heated air is natural due to difference in temperatures.

Solar energy is intercepted on the inclined aperture, which is glazed

for trapping infrared radiation, and prevents unnecessary circulation

of ambient air thereby maintaining the requisite temperature inside.

The drying trays have been arranged one over the other on an inclined

plane so that there is free circulation of heated air through the mass

kept for drying. The products can be dried under shade or exposed to

sunrays as desired. The dryer has provision for changing inclination

of the aperture by 15° to capture more solar energy depending upon

the season. Castor wheels make orientation easy in order to capture maximum

solar radiation. The drier may be left unattended even during rains,

as the products kept inside are not affected.

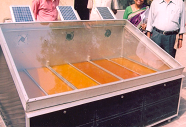

3.3.1.2 Step Type Solar

Cocoon Stifler

Silk cocoon stifling is generally carried out using an electric oven

or by using firewood and boiling water. The heat needed to kill the pupa

is obtained from solar radiation in a solar cocoon stifler. If the pupas

are not killed at the right time they grow out of the cocoon, damaging

the silk fibres. Hence stifling kills the pupa and 12-15 days time is

available for reeling the silk fibres. The solar cocoon stifler is a

box type unit that is provided with insulation and double glazed cover

for trapping solar heat. Wire mesh trays are arranged horizontally inside

the stifler and can be loaded easily by opening the side panels. It has

a small fan for re-circulating air for uniform heat distribution. An

electric heater of 2 KW and thermostatic control is also provided to

supply adequate heat during adverse weather. The quality of cocoon stifled

in the solar stifler is similar to the cocoon stifled in the conventional

process using the electric oven.

3.3.1.3 Simple Pyramid Shaped Solar Dryer

This dryer is conduction-convection type, pyramid shaped solar dryer

with a base to height ratio of 1:1.5. The frame of the dryer is fabricated

from wood and the trays (which also act like racks) are also of wooden

frame and wire mesh. UV stabilized black polythene sheets cover the

dryer. Since the wooden-wire-mesh trays are stored vertically, one

over the other, the dryer allows an effective drying area equal to

twice the size of the base area.

This dryer is conduction-convection type, pyramid shaped solar dryer

with a base to height ratio of 1:1.5. The frame of the dryer is fabricated

from wood and the trays (which also act like racks) are also of wooden

frame and wire mesh. UV stabilized black polythene sheets cover the

dryer. Since the wooden-wire-mesh trays are stored vertically, one

over the other, the dryer allows an effective drying area equal to

twice the size of the base area.

In summers the dryer attains temperatures of up to 15º to 20ºC

more than ambient and in winters about 5º to 10ºC more than

the ambient. Sunlight falling on the black UV stabilized polythene sheet

heats up the sheet.

The heat absorbed by the sheet heats the air inside the pyramid shaped

dryer. As the air gets heated inside, the convectional currents are initiated

due to variations in the air densities.

Hot air moving up to the top of the dryer carries moisture as vapour

from vegetables or fruits kept inside for drying in the wooden-wire-mesh

trays/ racks. The holes provided at the top of the dryer allow the hot

vapour to escape. Comparative colder air is drawn from outside through

holes provided at the base of the dryer.

This Cycle of hot air escaping from

the top and colder air being drawn from the base of the dryer removes

the moisture and dehydrating the materials, facilitating faster

drying of the vegetables, fruits or herbs in this solar dryer. Fruits like apple, banana and vegetables like ladies finger, bitter gourd, cauliflower, onions etc. can be dried in this dryer. Since the materials do not directly come in contact with Sunlight in this dryer, the materials retain their Colour on drying. The green leafy materials, like spinach, mehandi (henna), tulsi (basil leaves) and neem (Margosa) leaves dried in this solar dryer retain almost its natural green colour even when dried. Standard model solar dryer (shown in the photo) can dry about 20-kg of fresh vegetables, reducing weight to 2 to 3-Kg in two Sunny days. |

At the present cost of materials are incorporated in making this dryer, the standard model is prized at Rs. 2500. This dryer is being sold in North India around Delhi. Life of this solar drier is 5 years.

3.3.1.4 Data on Solar Dehydration of Selected Foods

Process data for fruits, vegetables, green leafy vegetables, spices,

food items is given in Table.3.4.

SI. No |

Product |

Drying

Time (hrs) |

Yield

(%) |

Ambient

temp. |

Cabinet

temp. (ºC) |

FRUITS |

|||||

1 |

Mango Bar (10

mm thick) |

20 |

45 |

40 |

65 |

2 |

Pineapple Bar

(10 mm thick) |

20 |

45 |

30 |

51 |

3 |

Papaya Bar (10

mm thick) |

20 |

45 |

30 |

51 |

4 |

Guava Bar (10

mm thick) |

35 |

45 |

31 |

48 |

5 |

Grapes |

25 |

20 |

31 |

53 |

6 |

Sapota Slices |

8 |

27 |

34 |

49 |

7 |

Sapota Bar (10

mm thick) |

20 |

36 |

34 |

42 |

VEGETABLES |

|||||

8 |

Potatoes |

4 |

30 |

31 |

50 |

9 |

Donda |

19 |

30 |

31 |

51 |

10 |

Carrot |

10 |

15 |

31 |

51 |

11 |

Tomato |

10 |

10 |

33 |

60 |

12 |

Mushrooms |

12 |

15 |

33 |

50 |

13 |

Bitter gourd |

6 |

11 |

26 |

42 |

14 |

Onion |

18 |

17 |

31 |

51 |

15 |

Amchur powder |

7 |

10 |

31 |

60 |

16 |

Coconut |

5 |

5 |

31 |

50 |

GREEN LEAFY VEGETABLES |

|||||

17 |

Curry leaves |

8 |

35 |

29 |

55 |

18 |

Spinach leaves |

15 |

8 |

29 |

55 |

19 |

Fenugreek leaves |

6 |

13 |

27 |

40 |

20 |

Tamarind leaves |

12 |

11 |

29 |

55 |

21 |

Gogu leaves |

15 |

16 |

30 |

55 |

22 |

Mint leaves |

5 |

17 |

29 |

55 |

23 |

Drumstick leaves |

5.5 |

15 |

29 |

55 |

24 |

Coriander leaves |

6 |

12 |

30 |

51 |

SPICES |

|||||

25 |

Ginger powder |

20 |

15 |

31 |

50 |

26 |

Mango ginger |

10 |

16 |

26 |

40 |

27 |

Garlic powder |

4 |

33 |

26 |

45 |

28 |

Red chillies |

15 |

34 |

32 |

56 |

29 |

Green chillies |

6 |

12 |

40 |

25 |

30 |

Pepper |

8 |

34 |

30 |

55 |

|

FOREST PRODUCE |

|||||

31 |

Karaya gum |

19 |

30 |

35 |

58 |

32 |

Karakkaya |

44.5 |

47 |

29 |

44 |

33 |

Sugandapala (budipalagadda) |

26 |

26.5 |

29 |

62 |

34 |

Aloe Vera |

9 |

2.8 |

33 |

49 |

35 |

Amla |

6.5 |

32 |

31 |

50 |

36 |

Honey |

5.5 |

91.5 |

39 |

65 |

|

MEDICINAL & HERBAL

PRODUCTS |

|||||

37 |

Rosemary |

15 |

30 |

32 |

58 |

38 |

Spirulina powder |

6 |

18 |

25 |

60 |

39 |

Tulasi leaves |

6 |

12 |

31 |

50 |

|

FOOD ITEMS |

|||||

40 |

Maida |

4 |

96 |

32 |

56 |

41 |

Vermicelli |

4 |

35 |

31 |

49 |

42 |

Noodles |

4 |

77 |

28 |

44 |

43 |

Pickled chillies |

24 |

25 |

31 |

49 |

44 |

Fish |

8 |

40 |

28 |

52 |

|

CHEMICAL POWDER |

|||||

45 |

Silicon Carbide |

3 |

80 |

31 |

60 |

46 |

Cellulose |

7 |

50 |

32 |

60 |