Matribhumi Improved Cook Stove (M-ICS)

| Categories: |

| Improved Cookstoves |

| Countries: |

| Nepal |

| Language: |

| English |

| Description of what does the solution provide: |

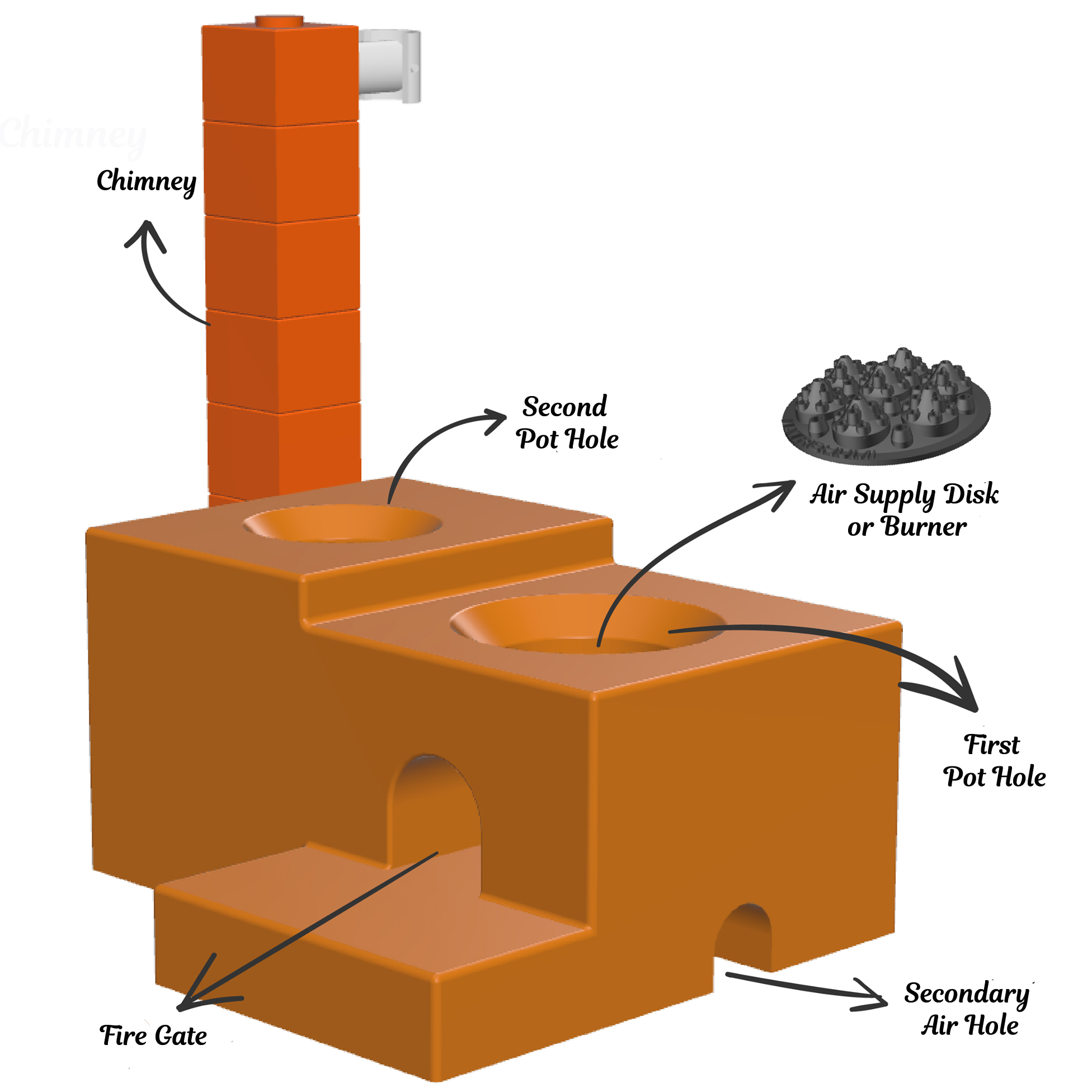

| The M-ICS is a two-pot hole mud stove with air supply disc or burner. The design consumes less fuel to cook a similar amount of food in comparison to the traditional stove. Besides, the M-ICS also contributes to reducing cooking time and creates a smokeless environment in the kitchen while cooking. The M-ICS comes with the air supply disc or burner is circular in shape, made from cast iron with seven perforated conical projections. The air supply disc is placed at the bottom of the fire chamber. Because of the optimized burner design and chimney draft effect, the stove does not need a fan and electricity supply to ignite and sustain burning. Its a natural burning. |

| Savings in resource use per day: |

| The M-ICS saves nearly 65% of firewood in comparison to 3-stone or traditional stove. |

| Efficiency.(in %): |

| 26.0% |

| Total particle Emissions: |

| 0 |

| Cost in money and in own time to construct: |

| The cost of the stove is NRS. 2500. It takes 4-5 hours to construct the stove structure and to erect the chimney. However, the stove needs 2-3 days of natural drying time before use. |

| Lifetime, years: |

| Recommended life as per data suggests 5-7 years with proper maintenance. |

| Maintenance needed: |

| Need to clean the chimney once every six months and requires regular application of soil and water mixture (a traditional/cultural approach to maintain surface gloss/shine on mud surfaces) to cover the M-ICS surfaces. |

| Resources needed in use: |

| Clay x100 kg, rocks and bricks x1 cu. feet whichever is convenient, salt and sugar as a binding material (200 gram each) and water x 20 Liters |

| Problems and limits in use: |

| Matribhumi has other Institutional stoves as per family size with change in burner size and stove structure. Also, pot rest can be used to rest bigger pots. However, the limitation is it cant be used as house heating application in higher Himalayas region. |

| Where and how can you get it or make it: |

| In Nepal, Matribhumi Urja Pvt. Ltd has all the copyrights for this M-ICS and its parts. However, training can be provided to the interested stakeholders or potential stove masters and enable them to build M-ICS. The air supply disc or burner designed has been patented by Matribhumi Urja Pvt. The trained stove master or personnel can construct the M-ICS at the site, i.e., in the kitchen, however, the technical accessories for M-ICS need to be arranged which includes technical accessories, fiber dye (recycled plastic block making die/mold 7 cubic inches) and polythene pipe inner keys, mud, rocks, salt and sugar. |

| Skills needed to produce, install, maintenance and use: |

| Installation needs a trained stove master or training; maintenance and use need short introduction only. Stove users manual could also help the users for the operation and regular maintenance. |

| Climate effect (if any): |

| The M-ICS significantly reduces firewood consumption and mitigates carbon emissions. One M-ICS reduces 2.91 tons of CO2 per year in the atmosphere. |

| Where is it used and how many users are there: |

| This stove has been promoted in various parts of Nepal like Kanchanpur, Kathmandu, Lalitpur, Pyuthan, Udayapur, Ramechhap, Kavre, Lamjung, Gorkha, Kalikot, Dolakha, Rautahat, Sindhuli, Doti, Achham, Bara, Sindhupalchok, Okhaldhunga, Kaski. Estimated 35000 installations across Nepal. Key project areas were earthquake-affected districts and Province 7. |

| Why is it successful? Success factors: |

| This M-ICS has three innovative components: air supply disk or burner, recycled plastic die/mold for stove and chimney construction. |

| More information: |

| https://www.facebook.com/MICSNepal/ https://cleancooking.org/sector-directory/matribhumi-urja-pvt-ltd/ |

| Organisational contact: |

| Centre for Rural Technology Nepal, CRT/N |

| Short description of construction, typical problems, materials needed: |

| A chimney cap is placed at the outlet of chimney connecting to M-ICS. As the smoke exits from the chimney, the cap provides safety from fire in mud houses. It also blocks air from outside to enter inside the stove and improves stove efficiency. Simple general equipments such as a screwdriver, hammer, measuring tape, insulation tape, nails, safety apron, installation kit carry bag and tester are required during M-ICS installation. Recycled Plastic Die/Mold and Polythene Pipe (HDPE) Inner Keys. The plastic die/mold for chimney block construction out of mud/clay is a recycled LDPE cubical mold box that comes in a size of 7in x 7in x 6in. Clay/mud is stuffed and compressed inside mold and the molded clay blocks are dried under natural condition for 2 days before final installation. During the construction of M-ICS, six inner keys of polythene pipes are used. These pipes are designed with fixed dimension to ensure standard inner parts of the M-ICS. The details of the k and its use are explained below: a) First fire chamber/place of air supply disc (burner) key b) Secondary Air Hole key c) Fire wood post key d) Second fire chamber key e) Linkage key (between first and second fire chambers) f) Chimney place key g) Chimney block key |

| 1-2 min video on how to make it: |

| Link to video on YouTube |

| Date of post creation: |

| 2022-01-24 |

| Date of last changes: |

| 2023-10-03 |

The database for Eco-Village Development in South Asia was developed by the NGO cooperation project:

“Next generation low carbon, climate resilient Eco-Village Development in South Asia “ in 2021-23.

The database includes local sustainable solutions, media (photos, graphics, videos), publications, and organisations.

Read more at About

“Next generation low carbon, climate resilient Eco-Village Development in South Asia “ in 2021-23.

The database includes local sustainable solutions, media (photos, graphics, videos), publications, and organisations.

Read more at About