BIOGAS

|

BIOGAS |

The interest in biogas as an alternative fuel comes mainly from its clean burning qualities and its domestic resource base. Because of the gaseous nature of this fuel, it must be stored onboard a vehicle in either a compressed form like compressed natural gas (CNG) at 200-240 atmospheres or as liquefied form like liquefied natural gas (LNG) at typically 1,4 - 10 atmospheres.

Biogas

produced in biogas plants or landfill sites is primarily composed of methane and

carbon dioxide with smaller amounts of hydrogen sulphide and ammonia. Trace

amounts of other gases like hydrogen, nitrogen or carbon monoxide are also

present in the biogas. Usually the mixed gas is saturated with water vapour and

may contain dust particles.

The

characteristics of biogas are somewhere comparable natural gas. The energy

content is defined by the concentration of methane. 10% of methane in the dry

gas corresponds approximately to 1

kWh per m3.

For biogas as a fuel, most of the impurities have to be removed. They may cause

corrosion, deposits and damage to the equipment. Substances which need to be

removed include hydrogen

sulphide, water

For

the use of biogas in ordinary Otto engines (engines running on gasoline) biogas

must be upgraded to contain at least 85% methane and 14% nitrogen. This is the

minimum fuel

quality

for which the natural gas fuelled vehicles are approved. It is also important

that the gas quality is maintained at a fix composition in order to prevent an

increased NOx

concentration.

Purification of biogas is primarily achieved by carbon dioxide removal. This

enhances the energy value of the gas.

For

the use of biogas in ordinary Otto engines (engines running on gasoline) biogas

must be upgraded to contain at least 85% methane and 14% nitrogen. This is the

minimum fuel

quality

for which the natural gas fuelled vehicles are approved. It is also important

that the gas quality is maintained at a fix composition in order to prevent an

increased NOx

concentration.

Purification of biogas is primarily achieved by carbon dioxide removal. This

enhances the energy value of the gas.

Biogas to methane upgrading plant in Sweden.

Hydrogen sulphide is always present in biogas, although concentrations vary with the feedstock. It has to be removed in order to avoid corrosion in vehicle equipment like compressors, gas storage tanks and engines. Hydrogen sulphide is extremely reactive with most metals and the reactivity is enhanced by concentration and pressure, the presence of water and elevated temperatures. Because of the potential problems which hydrogen sulphide can cause, it is usually removed early in the process of biogas upgrading.

The

reasons why the biogas (natural gas) is used as the alternative fuel for

vehicles include:

Reduction of CO2 emissions from transport sector especially in cities.

Reduction

of fuel imports

Reduction

of methane emissions (10%

of the global methane emissions comes from landfills

Increased employment in the agricultural sector.

Reduction

of unpleasant odors.

Less

sanitary problems

Biogas vehicles.

Number of natural gas fuelled vehicles in the world (2004)

| Number of NG fuelled vehicles | Number of NG fuel stations | |

| Argentina | 1 100 000 | 1154 |

| Brazil | 686 305 | 518 |

| Pakistan | 475 000 | 500 |

| Italy | 381 250 | 460 |

| India | 222 306 | 192 |

| USA | 130 000 | 1300 |

| China | 79 600 | 300 |

| Egypt | 51 997 | 86 |

| Venezuela | 44 146 | 149 |

| Ukraine | 45 000 | 130 |

In Europe car manufacturers have a long lasting interest in natural gas

vehicles. Beside Fiat company which

was one of the first natural gas powered car manufacturer there are now

almost all car manufacturers offering such models. Now four car engine

manufacturers produce 10 different bus models and seven truck models. Some time

ago truck engines still had to be imported from the USA.

In Europe car manufacturers have a long lasting interest in natural gas

vehicles. Beside Fiat company which

was one of the first natural gas powered car manufacturer there are now

almost all car manufacturers offering such models. Now four car engine

manufacturers produce 10 different bus models and seven truck models. Some time

ago truck engines still had to be imported from the USA.

Buses running on compressed natural gas in city of Lille, France.

Production and utilisation of biogas for energy purposes is strongly supported by the European Union. Biogas production is steadily increasing in the EU and reached 4,26 million ton oil equivalent in 2004.

Biogas is a valuable fuel which is in many countries produced in purpose built digesters filled with the feedstock like dung or sewage. Digesters range in size from one cubic meter for a small ‘household’ unit to more than thousand cubic meters used in large commercial installation or farm plants. The input may be continuous or in batches, and digestion is allowed to continue for a period of few days to a few weeks. The bacterial activity in feedstock generates heat, but in cold climates additional heat is normally required to maintain the ideal process temperature of at least 35 degrees Celsius. A well-run digester can produce 200-400 m3 of biogas with a methane content of 50% to 75% for each dry tonne of input.

Recently

there are more than 500 landfill biogas plants in

Nevertheless there is a huge potential for biogas as the alternative and renewable fuel. In densely populated areas the effect of reduced emission from transportation brings a higher environmental effect than production of electricity.

The main obstacle in biogas production as the alternative fuel are high cost of upgrading equipment, which is too expensive for small scale systems.

Lorry collecting organic wastes for biogas production in Stockholm.

Biogas pump in Sweden.

After its production, purified biogas is usually collected and transported by trucks to pumping stations like in Stockholm. In other places the biogas is transported over a special gas line to the city like in Linköping, Sweden.

Biogas car at pump station in Stockholm.

Biogas grid injection facility.

In the Switzerland the biogas is transported via the natural gas grid. The fuelling at the pumping station is virtual, i.e. customers usually buy natural gas however, on a data base the provider keeps exactly track on how much biogas is introduced and how much has been used at their pumping stations. In Switzerland it is the state who does the control because the biogas is tax free.

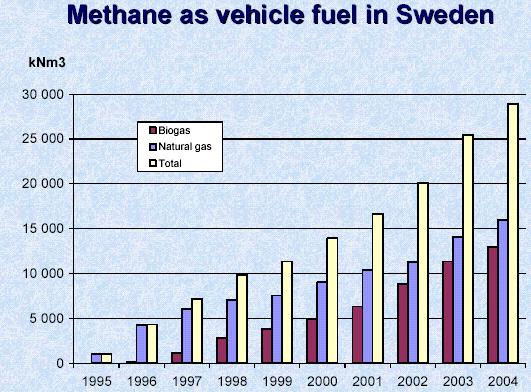

Sweden is one the most advanced country in the world in terms of biogas-power cars. Sales of these cars increased by 49 percent in 2005. There are more than 3000 cars running on biogas and 19 pump stations in the city of Göteborg alone. The world's largest biogas plant and the first train running on biogas also operate in this country. The plant to be built in the city of Göteborg will have a capacity of producing 1,600 cubic meters of biogas per hour.

First biogas fuelled train in the world.

For more information on biogas production see the chapter Biomass

It

has been demonstrated that commercially available heavy-duty natural gas fuelled

trucks reach over 90% reductions of carbon monoxide (CO), particulate matter and

more than 50% reduction in nitrogen oxides (NOx) in comparison to common trucks

burning diesel fuel.

Motorcycle running on biogas.