|

|

|

Water constantly

moves through a vast global cycle, in which it evaporates (due to the activity

of the Sun) from oceans, seas and other water reservoirs, forms clouds,

precipitates as rain or snow, then flows back to the ocean. The energy

of this water cycle, which is driven by the sun, is tapped most efficiently

with hydropower. The use of water to generate mechanical power is a very

old practice. A flowing stream can make a paddle turn, but a waterfall

can spin a blade fast enough to generate electricity. The real key in the

magnitude of waterpower is the physical height difference achieved between

source and sink - the distance through which the water falls.

Water constantly

moves through a vast global cycle, in which it evaporates (due to the activity

of the Sun) from oceans, seas and other water reservoirs, forms clouds,

precipitates as rain or snow, then flows back to the ocean. The energy

of this water cycle, which is driven by the sun, is tapped most efficiently

with hydropower. The use of water to generate mechanical power is a very

old practice. A flowing stream can make a paddle turn, but a waterfall

can spin a blade fast enough to generate electricity. The real key in the

magnitude of waterpower is the physical height difference achieved between

source and sink - the distance through which the water falls.

Another methods of harnessing water's energy include utilisation

of the temperature of ocean water in a thermal transfer process, waves

and tidal power. The waves are a direct result of wind, which itself is

cause by uneven heating of the ground and oceans by the Sun. Of the several

types of hydropower, only the origin of the tides is not related to the

Sun. The gravitational pull of the moon is responsible for the tides, which

vary in magnitude by location according to latitude and geography.

When considered as a whole, the energy locked within Earth's water cycle and ocean waves is extremely large, but harnessing this energy has proved to be exceedingly difficult. There are many different ways to harness the energy in water. The most common way of capturing this energy is hydroelectric power, electricity created by falling water.

The principal advantages of using hydropower are its large renewable domestic resource base, the absence of polluting emissions during operation, its capability in some cases to respond quickly to utility load demands, and its very low operating costs. Hydroelectric projects also include beneficial effects such as recreation in reservoirs or in tail water below dams. Disadvantages can include high initial capital cost and potential site-specific and cumulative environmental impacts.

HISTORY

Simple water-wheels have been used already in ancient times to

relieve man of some forms of hard manual labour. Water power was probably

first mentioned by the Greeks, around 4000 B.C. Greeks used hydro power

to turn water wheels for grinding wheat into flour as well. Much later,

but long before the advent of the steam engine, the art of building

large water-wheels and the use of considerable power capacities was highly

developed. The use of this natural energy resource became even easier

and more widespread with the invention of the water turbine in the

early 1800's and hydro power was quickly adapted from mechanical uses,

such as grist mill, to spinning a generator to produce electricity. The

first small industries emerged soon after in many regions of Europe and

North America, powered by water turbines.

In later years, when cheap oil became available world-wide, interest

in hydro power was lost to a great extent in many areas, but today

the situation is different again. Governments, policy-makers, funding

and lending agencies, institutions and individuals take a growing

interest. This led -and still does -to the reassessment of many projects

once found not feasible; the identification of new sites and potentials,

and a number of other activities related to hydro development.

![]()

HYDRO

POWER PLANTS

Amongst renewable energy sources, hydroelectric power seems to be

the most desirable for utilities and its economic feasibility has been

successfully proven. Power stations with a capacity of up to 10 GW have

been built and it is estimated that there are economic resources for 3,000

GW world-wide, compared to 10,000 GW world primary energy consumption.

In Europe, however, most hydroelectric potential has been realised, with

Norway deriving 98% of its energy consumption from water power and the

West German government concluding that there are no more sites available

for exploitation. World-wide it is estimated that about 10% of resources

have been realised, with most potential remaining in Africa and Asia.

Consumption of hydro power in the world.

Present worlds total installed hydro power capacity is about 630 000 MW. The data are uncertain because the contributions from small hydro power plants and private systems are difficult to estimate, but it is assumed that these facilities can add just a few per cent to the total figure. The annual power production world-wide is 2200 TWh (billion kilowatt hours), which means that the power plants are running at 40 % of its rated power.

The largest hydroelectric complex in the world is on the Parana River, between Paraguay and Brazil. It is called the Itaipu Dam and its 18 turbines produce 12 600 MW of electricity. Hydro power is growing in many regions of the world. China and India pledged increases in large-scale hydroelectric development. In 1999 China completed its 3300 MW Ertan hydroelectric station which has six generating units, each with a capacity of 550 megawatts. Ertan is Asia's second tallest dam and China's largest electricity supplier.

The largest hydro power plants.

Hydroelectric projects currently under construction in China amount to some 32 000 MW of installed generating capacity. In India, 12 large-scale projects - adding up to 3700 MW of installed hydroelectric capacity - have been given government approval. All the projects are scheduled for completion by 2002. Construction on the world's largest hydroelectric project, the 18,2 GW Three Gorges Dam (China), entered Phase 2 of a three-phase process in 1998. Although construction on the dam was temporarily suspended in August 1988 because of the extensive flooding along the Yangtze, Phase 2 is still scheduled for completion in 2003, when the dam will start generating electricity. Phase 3 should end in 2009 with the beginning of full power generation. About USD 3.7 billion has already been spent on construction of Three Gorges Dam, including temporary diversion of the Yangtze and draining of the building site so that construction of the dam can continue. Upon completion, the project will extend 2 kilometres across the Yangtze and will be 200 meters tall, creating a 550 km long reservoir. The official Chinese estimate for the cost of the entire project is USD 25 billion. Three Gorges Dam has been the subject of much controversy. Environmental and social problems related to this projects are enormous. Water pollution along the Yangtze will double as the dam traps more than 50 kinds of pollutants from mining operations, factories, and human settlements that used to be washed out to sea by the strong currents of the river. Heavy silt in the river will deposit at the upstream end of the dam and clog the major river channels of Chongqing. An estimated 1.1 million to 1.9 million people will have to be resettled before the reservoir is created; around 1,300 archaeological sites will have to be moved or flooded; and the habitats of several endangered species and rare plants will be jeopardised. In 1996, the U.S. Export-Import Bank declined to grant guarantees for U.S. companies hoping to work on Three Gorges Dam, citing the potential environmental problems.

Construction is also underway on a pumped-storage station in Tibet at Yamzho Yumco Lake. The Tibetan station is being constructed at an elevation of 4 000 to 5,000 meters, the highest project in the world. In 1997, China announced plans to build a hydroelectric project along Tibet's Brahmapoutre river, near the Yalutsan mountain, which could generate a proposed 40 000 MWh per year.

Many countries of Central and South America rely heavily on hydroelectricity for electricity generation. In Brazil - which accounts for about 40 percent of the region's total installed capacity - 86 percent of the 59 000 MW of total installed capacity in 1996 consisted of hydropower. Hydroelectric dams also account for 50 percent or more of the total installed generating capacity in Chile, Colombia, Paraguay, Peru, and Venezuela. Although many of the region's hydroelectric resources have been developed, there are still plans to add substantial capacity in near future. Brazil still has more hydroelectric projects under construction or planned for future installation than any other country in the Central and South America region. In September 1997, the final turbine was installed in the 3 000 MW Xingó hydroelectric power facility on the São Francisco River at Piranhas. The USD 3.1 billion project accounts for 25 percent of the installed capacity in Northeast Brazil. Other large hydroelectric facilities currently under construction in Brazil include the 1450 MW Itá hydroelectric plant, which is scheduled for completion in mid-2000, and the 1140 MW Machadinho hydroelectric plant, which is scheduled for completion in 2003; both facilities are located on the Uruguay River. Finally, there are also plans to expand the 12600 MW Itaipu project held jointly between Brazil and Paraguay. The facility is to be expanded by 1400 MW at a cost of about USD 200 million.

ITAIPU - world largest hydro power plant.

More pictures

from Itaipu

HYDROPOWER POTENTIAL

There are two main factors that determine the generating potential

at any specific site: the amount of water flow per time unit and the vertical

height that water can be made to fall (head). Head may be natural due to

the topographical situation or may be created artificially by means of

dams. Once developed, it remains fairly constant. Water flow on the

other hand is a direct result of the intensity, distribution and duration

of rainfall, but is also a function of direct evaporation, transpiration,

infiltration into the ground, the area of the particular drainage

basin, and the field-moisture capacity of the soil. Runoff in rivers

is a part of the hydrologic cycle in which -powered by the sun -

water evaporates from the sea and moves through the atmosphere to

land were it precipitates, and then returns back to the sea by overland

and subterranean routes.

Hydro power potential can be estimated with the help of river flows around the world. The results show that this total resource potential is 50 000 TWh per year – only a quarter of the world precipitation, but still over four times the annual output of all the world present power plants. Realistic resource potential which is based on local conditions of world rivers is in range 2 - 3 TW with an annual output of 10 000 - 20 000 TWh (UN 1992). But the important question remains : how much of hydro potential can we afford to use (see the chapter on environmental aspects).

A theoretical yearly production potential of 10.000 TWh of electrical energy means that the same amount of electrical energy produced in thermal plants with oil as fuel would require approximately 40 million barrels of oil per day. If this is compared to the world consumption of petroleum products, which amounted to around 80 million barrels per day in 1995. For developing countries, who together possess almost 60 % of the installable potential, the magnitude is striking.

COST

Hydro power plants are very attractive for the investors. This is

due to the relative low investment costs and competitive price of electricity

produced. Moreover the life span o hydro facilities is considerably longer

than for conventional fossil power plants. There are hydro power plants

which run for almost 100 years.

PROBLEMS

OF HYDRO POWER

The main reasons that hydro power plants are not build everywhere

are that they are costly and require large bodies of water relatively close

to inhabitants. According to the World Bank, “developing countries will

need to raise an estimated USD 100 billion by the year 2000 for hydroelectric

plants currently in the planning stage.” Another arising problems are the

effects of dams on river ecosystems and social problems related to relocation

of inhabitants.

ENVIRONMENTAL ASPECTS OF HYDRO

POWER PLANTS

A

watercourse is an ecological system where changes within one component

may create a series of spread-effects. For instance, changes in the water

flow may affect the quality of the water and the production of fish downstream.

Dam barriers may greatly change the living conditions for fish. In addition

to the emergence of a major or completely new lake, the dam may divide

upstream fish from downstream fish, and block their migration routes.

A

watercourse is an ecological system where changes within one component

may create a series of spread-effects. For instance, changes in the water

flow may affect the quality of the water and the production of fish downstream.

Dam barriers may greatly change the living conditions for fish. In addition

to the emergence of a major or completely new lake, the dam may divide

upstream fish from downstream fish, and block their migration routes.

Environmental changes may be traced far downstream, at times even

out into the sea. In the tropics there may be great seasonal variations

as to the amount of precipitation, and in dry periods evaporation from

lakes and reservoirs may be considerable. This may affect the water level

of the reservoirs more dramatically than in temperate areas. The watercourse

and its watershed mutually influence each other. The watercourse, for example,

may affect the local climate and the ground-water level in surrounding

areas. The sedimentation taking place in a reservoir can often lead to

an increased erosion downstream, i.e. an increase in the total erosion.

Changes in water flow and water level will also lead to changes in the

transportation of sediments.

During the construction phase the transport of mud and sediments

will be especially large downstream from the construction area. Excavation

and tunnelling may lead to greatly reduced water quality and problems for

those dependent on the water.

GROUNDWATER

The groundwater level is important for the ecosystem‘s composition

and development of plant and animal species. Groundwater is particularly

important as a drinking-water source in most countries. The filling of

a reservoir of hydro power plant and the flow of a watercourse are of great

importance to the groundwater level and for the feeding of the groundwater

reservoirs. A reservoir, together with the changes and variations of the

water level caused by its operation, will change the groundwater level

in surrounding areas. These areas may in turn influence the quality of

the water and the sediment transport of the watercourse as a result of

area run-off and erosion.

EXCESSIVE FERTILIZATION

Whenever nutrients are trapped in a reservoir, the result may be

excessive fertilisation - eutrophication - in the reservoir. It may lead

to an increased growth of algae or large amounts of higher-order aquatic

plants. A substantial production of organic matter in the reservoir, or

the supply of external organic matter, may cause anaerobic conditions -

lack of oxygen - in the deep-water layers.

On the whole, shallow lakes with a large surface area are most at

risk, partly because the reserve of oxygen in the deep-water layers is

limited in proportion to the productive area in the top layers. In deep,

narrow lakes the oxygen content in the deep-water layers will be sufficient

to recycle organic matter sinking down, provided there is a regular circulation

of the waters. This is not always the case in the tropics. If the watercourse

is initially rich in nutrients, the risk of eutrophication will increase.

Evaporation may cause a concentration of nutrients, leading to excessive

fertilisation or eutrophication. Tropical soil normally has-a low humus

content. This, combined with the great seasonal variations as to the amount

of precipitation, and the fact that precipitation often comes in heavy

showers, may cause considerable erosion. The transportation of eroded sediments

will be halted and deposited in a reservoir. The reservoir's lifetime may

in this way be reduced. Transport of sediments and nutrients tends to play

a crucial role in the ecosystem of a watercourse. The population's utilization

of nature and natural resources may be completely dependent on floods and

waterborne sediments and nutrients.

TRANSPORT OF NUTRIENTS

A reservoir serves as a trap for nutritious elements and mud flowing

in, possibly leading to a considerable reduction of the total transport

of nutrients downstream. In addition, the annual variations in supply downstream

may undergo changes. This may reduce the biological production all the

way to the sea. There are grave examples of marine fishing being impaired

in the wake of a major dam development.

FISH

The composition of fish species may be altered, since reproduction

for some species may be hindered if the operation involves changes in the

water level during the spawning period. Artificial reservoir tends to contain

a less varied composition of species than a natural lake. Changes in the

water flow and water-flow pattern may radically alter nutrient and spawning

conditions downstream. The primary production as well as the direct accessibility

of nutriment for fish will change. Changes made to the downstream floods,

as a result of water control, may be decisive. At dam and turbine outlets

a surfeit of gas may occur, principally of nitrogen, which can cause death

among fish.

Some hydro power plants are equipped with fish ladders.

FLORA AND FAUNA

Submerging and water-flow changes, moreover, will lead to changes

in the fauna and vegetation beyond the watercourse as such. Large reservoirs

will exert a considerable direct impact on the flora and fauna of the hydro

power plant area through submerging the area permanently or periodically.

Animals may to some extent move to new habitats beyond the reservoir area,

provided that suitable conditions are to be found. But normally the types

and species of nature existing in areas being submerged must be considered

as lost.

It is difficult to predict in general terms how changes beyond the

submerged area will turn out. Local climatic changes and changes to the

ground-water level may affect the flora and fauna. Valuable types and species

of nature may be lost. A general activity increase in the area, such as

traffic, noise etc., may also affect the fauna in a negative way. This

especially pertains to the construction period.

Further, a reduced water flow or changed flow pattern downstream

may influence the flora and fauna. The effects may be direct ones in that

the flora and fauna react to the water flow, or the effects may be indirect

owing to changes in the ground-water level and the transport of nutrients.

![]()

POPULATION MOVEMENTS

Large hydro power plants with dams require large reservoir and discharge

areas. Many people have to be evacuated to make room for these areas. This

could lead to a completely new situation for people who have lived in a

relatively small, protected environment. Housing, land distribution, working

conditions and way of life may change radically. The impacts will depend

upon the size and location of the project. With major dam developments

they can be serious.

Social consequences are likely to arise if the population concerned

should be pressured into settling down in, or exploiting, more marginal

and ecologically vulnerable areas than the ones they have traditionally

utilized. These impacts may further aggravate their situation. Such indirect

environmental effects can cause considerable ecological problems, with

consequences for the entire project area.

Indigenous groups affected by hydropower development may be particularly

deprived. Their principle socio-cultural conditions together with their

traditional connection to land, water and other natural resources, tend

to make them unadaptable to changes and new activities. The size of many

hydropower projects and the rapid alterations in ecological conditions

that may arise, usually allow little room for readjustment. The transfer

of indigenous groups may endanger their entire cultural system. Such minorities

are particularly exposed, as they tend to have little political influence

and possibility of securing their own interests.

As a whole, the consequences of dam development can involve great

damage to traditional ways of life and cultural expressions. Changes in

terms of social, economic and religious organisation can create a series

of indirect social impacts which are difficult to foresee during the planning

of the project. Cultural landscapes, ancient monuments, holy places, burial

grounds etc. are often areas and objects of great importance to a local

population's cultural activities. Should such areas and objects be affected

by a project, the cultural identity of the population might be at risk.

DAM BREACH -UNCONTROLLED FLOODING

A dam breach seldom occurs, but owing to the enormous consequences

which it may involve, the impacts of a breach should be assessed. The risk

of casualties and damaged property or technical installations must be considered

the most serious consequences, but the impacts on the natural environment

can also be considerable.

Statistically, the combination of a flood in the upstream watershed

of the dam and faults in the spillway are the most frequent causes of accidents.

Secondary causes are foundation errors or water seepage. At high water

levels in the reservoirs, landslides of earth and rocks from the embankment

above or inside the reservoir may cause flood waves so massive that water

may spill over the total or partial width of the dam. If the dam is an

embankment dam, this may lead to the dam itself being damaged. Special

care should be taken if a major dam is planned in an area exposed to earthquakes.

TECHNOLOGY

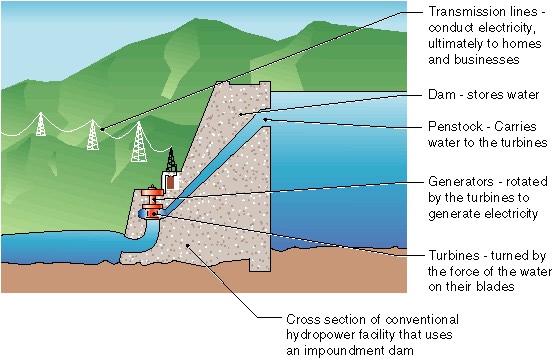

![]() In hydro power

plants the kinetic energy of falling water is captured to generate electricity.

A turbine and a generator convert the energy from the water to mechanical

and then electrical energy. The turbines and generators are installed either

in or adjacent to dams, or use pipelines (penstocks) to carry the pressured

water below the dam or diversion structure to the powerhouse. The power

capacity of a hydropower plant is primarily the function of two variables:

(1) flow rate expressed in cubic meters per second (m3/s), and (2) the

hydraulic head, which is the elevation difference the water falls in passing

through the plant. Plant design may concentrate on either of these variables

or both.

In hydro power

plants the kinetic energy of falling water is captured to generate electricity.

A turbine and a generator convert the energy from the water to mechanical

and then electrical energy. The turbines and generators are installed either

in or adjacent to dams, or use pipelines (penstocks) to carry the pressured

water below the dam or diversion structure to the powerhouse. The power

capacity of a hydropower plant is primarily the function of two variables:

(1) flow rate expressed in cubic meters per second (m3/s), and (2) the

hydraulic head, which is the elevation difference the water falls in passing

through the plant. Plant design may concentrate on either of these variables

or both.

|

From the energy conversion point of view, hydro power is a

technology with very high efficiencies, in most cases more than double

that of conventional thermal power plants. This is due to the fact that

a volume of water that can be made to fall a vertical distance, represents

kinetic energy which can more easily be converted into the mechanical

rotary power needed to generate electricity, than caloric energies.

Equipment associated with hydropower is well developed, relatively

simple, and very reliable. Because no heat (as e.g. in combustion)

is involved, equipment has a long life and malfunctioning is rare. The

service life of an hydroelectric plant is well in excess of 50 years. Many

plants built in the twenties - the first heyday of hydroelectric power

- are still in operation.

Since all essential operating conditions can be remotely monitored and adjusted by a central control facility, few operating personnel are required on site. Experience is considerable with the operation of hydropower plants in output ranges from less than one kW up to hundreds of MW for a single unit. |

TYPES OF HYDROPOWER FACILITIES

Hydropower technology can be categorized into two types: conventional

and pumped storage. Another way of classification of hydro power plants

is according to :

![]() Rated power

capacity (big or small)

Rated power

capacity (big or small)

![]() Head of water

(low, medium and high heads)

Head of water

(low, medium and high heads)

![]() The type of

turbine used (Kaplan, Francis, Pelton etc.)

The type of

turbine used (Kaplan, Francis, Pelton etc.)

![]() The location

and type of dam, reservoir.

The location

and type of dam, reservoir.

Conventional hydropower plants use the available water energy from a river, stream, canal system, or reservoir to produce electrical energy. Conventional hydropower can be further divided between impoundment and diversion hydropower. Impoundment hydropower uses dam to store water. Water may be released either to meet changing electricity needs or to maintain a constant water level. Diversion hydropower channels a portion of the river through a canal or penstock, but may require a dam. In conventional multipurpose reservoirs and run-of-river systems, hydropower production is just one of many competing purposes for which the water resources may be used. Competing water uses include irrigation, flood control, navigation, and municipal and industrial water supply.

PUMPED STORAGE PLANTS

|

Pumped storage hydro-electricity is a remarkably simple principle.

To start with, two reservoirs at different altitudes are required. Water

stored at height offers valuable potential energy. During periods of high

electrical demand, the water is released to the lower reservoir to generate

electricity. When the water is released, kinetic energy is created by the

discharge through high-pressure shafts which direct the water through turbines

connected to generator/motors. The turbines power the generators to create

electricity. After the generation process is complete, water is pumped

back to the upper reservoir for storage and readiness for the next cycle.

The process usually takes place overnight when electricity demand is at

its lowest.

While pumped storage facilities are net energy consumers, they are valued by a utility because they can be rapidly brought on-line to operate in a peak power production mode. This process benefits the utility by increasing the load factor and reducing the cycling of its base load units. In most cases, pumped storage plants run a full cycle every 24 hours. |

COMPONENTS OF HYDRO POWER PLANT

Most conventional hydropower plants include following major components:

![]() Dam. Controls

the flow of water and increases the elevation to create the head. The reservoir

that is formed is, in effect, stored energy.

Dam. Controls

the flow of water and increases the elevation to create the head. The reservoir

that is formed is, in effect, stored energy.

![]() Turbine. Turned

by the force of water pushing against its blades.

Turbine. Turned

by the force of water pushing against its blades.

![]() Generator.

Connects to the turbine and rotates to produce the electrical energy.

Generator.

Connects to the turbine and rotates to produce the electrical energy.

![]() Transformer.

Converts electricity from the generator to usable voltage levels.

Transformer.

Converts electricity from the generator to usable voltage levels.

![]() Transmission

lines. Conduct electricity from the hydropower plant to the electric distribution

system.

Transmission

lines. Conduct electricity from the hydropower plant to the electric distribution

system.

![]() In some hydro

power plants also another component is present – penstock, which carries

water from the water source or reservoir to the turbine in a power plant.

In some hydro

power plants also another component is present – penstock, which carries

water from the water source or reservoir to the turbine in a power plant.

Water turbines may be classified in different ways. One way of classification is according to the method of functioning (impulse or reaction turbine); another way is according to the design (shaft arrangement and feed of water). Water turbines may operate as turbines, as pump turbines or as a combination of both. They may be of the single regulated or double regulated type. Turbines may also be classified according to their specific speed.

Impulse turbines use a nozzle at the end of the pipeline that converts the water under pressure into a fast-moving jet. This jet is then directed at the turbine wheel (also called runner), which is designed to convert as much of the jet's kinetic energy possible into shaft power. Common impulse turbines are Pelton and cross-flow. In reaction turbines the energy of the water is converted from pressure to velocity within the guide vanes and the turbine wheel itself. Spinning of the turbine is a reaction to the action of the water squirting from the nozzles in the arms of the rotor. The typical example of reaction turbine is a Francis turbine. The advantage of small hydro power reaction turbine is that it can use the full head available at a site. An impulse turbine must be mounted above tailwater level. The advantage of impulse turbine is that it is very simple and cheap and as the water flow varies , water flow to the turbine can be easily controlled by changing nozzle size. In contrast most small reaction turbines cannot be adjusted to accommodate variable water flow.

Most hydraulic turbines consist of a shaft-mounted water-wheel or “runner” located within a water-passage which conducts water from a higher location (the reservoir upstream from a dam) to a lower one (the river below a dam). Some runners look very similar to a boat propeller, others have more complex shapes. The turbine runner is installed in a water passage that lets water from the reservoir flow pass the runner blades, which makes the turbine spin.

Almost all hydraulic turbine/generator units turn at a constant speed.

The constant speed one type of turbine/generator operates at may be considerably

different from the speed of another. The best speed for each type of turbine

is set during design, and a generator is then designed that will produce

usually alternating current at that speed. A device called a governor keeps

each unit operating at its proper speed by operating flow-control gates

in the water-passage. There are several types of turbine designs like Pelton,

Kaplan, Francis or cross-flow turbine.

![]()

PELTON TURBINE

The principle

of the old water-wheel is embodied in the modern Pelton turbine. This turbine

has a similar look and physical principle like a classic water wheel. A

Pelton turbine is used in cases where large heads of water are available

(more than 40 m). The Pelton turbine is used for heads up to 2000 m. Below

250 m, mostly the Francis turbines are given preference. Today the maximum

output lies at around 200 MW.

The principle

of the old water-wheel is embodied in the modern Pelton turbine. This turbine

has a similar look and physical principle like a classic water wheel. A

Pelton turbine is used in cases where large heads of water are available

(more than 40 m). The Pelton turbine is used for heads up to 2000 m. Below

250 m, mostly the Francis turbines are given preference. Today the maximum

output lies at around 200 MW.

|

Since then the turbine has been considerably improved in all respects

and the output of power has increased. Power is extracted from the high

velocity jet of water when it strikes the cups of the rotor (runner). There

is a maximum of 40 cup-like paddles jointed in two half-cups each water

is being squirted through nozzles onto the blades where it is deflected

by 180° and thus gives almost all of its energy to the turbine. By

the reversal almost all the kinetic energy is transferred into force of

impulse at the outer diameter of the wheel. Because of the symmetry of

the flow almost no axial force is created at the runner.

From the design point of view, adaptability exists for different flow and head. Pelton turbines can be equipped with one, two, or more nozzles for higher output. In manufacture, casting is commonly used for the rotor, materials being brass or steel. This necessitates an appropriate industrial infrastructure. Pelton turbines require only very little maintenance. |

FRANCIS TURBINE

In the great

majority of cases (large and small water flow rates and heads) the type

of turbine employed is the Francis or radial flow turbine. The significant

difference in relation to the Pelton turbine is that Francis (and Kaplan)

turbines are of the reaction type, where the runner is completely submerged

in water, and both the pressure and the velocity of water decrease from

inlet to outlet. The water first enters the volute, which is an annular

channel surrounding the runner, and then flows between the fixed guide

vanes, which give the water the optimum direction of flow. It then enters

the runner, which is totally submerged, changes the momentum of the water,

which produces a reaction in the turbine. Water flows radially i.e., towards

the centre. The runner is provided with curved vanes upon which the

water impinges. The guide vanes are so arranged that the energy of the

water is largely converted into rotary motion and is not consumed

by eddies and other undesirable flow phenomena causing energy losses. The

guide vanes are usually adjustable so as to provide a degree of adaptability

to variations in the water flow rate and in the load of the turbine.

In the great

majority of cases (large and small water flow rates and heads) the type

of turbine employed is the Francis or radial flow turbine. The significant

difference in relation to the Pelton turbine is that Francis (and Kaplan)

turbines are of the reaction type, where the runner is completely submerged

in water, and both the pressure and the velocity of water decrease from

inlet to outlet. The water first enters the volute, which is an annular

channel surrounding the runner, and then flows between the fixed guide

vanes, which give the water the optimum direction of flow. It then enters

the runner, which is totally submerged, changes the momentum of the water,

which produces a reaction in the turbine. Water flows radially i.e., towards

the centre. The runner is provided with curved vanes upon which the

water impinges. The guide vanes are so arranged that the energy of the

water is largely converted into rotary motion and is not consumed

by eddies and other undesirable flow phenomena causing energy losses. The

guide vanes are usually adjustable so as to provide a degree of adaptability

to variations in the water flow rate and in the load of the turbine.

The guide vanes in the Francis turbine are the elements that direct

the flow of the water, just as the nozzle of the Pelton wheel does. The

water is discharged through an outlet from the centre of the turbine.

In design and manufacture, Francis turbines are much more complex

than Pelton turbines, requiring a specific design for each head/flow condition

to obtain optimum efficiency. Runner and housing are usually cast, on large

units welded housings, or cast in concrete at site, are common.

With a Francis turbine, downstream pressure can be above zero. Precautions

must be taken against water hammer with this type of turbine. Under the

emergency stop, the turbine overspeeds. One would think that more water

is going through the turbine than before the trip occurred since the turbine

is spinning faster. However, the turbine has been designed to work efficiently

at the design speed, so less water actually flows through the turbine during

overspeed. Pressure relief valves are added to prevent water hammer due

to the abrupt change of flow. Besides limiting pressure rise, the pressure

relief valve prevents the water hammer from stirring up sediment in the

pipes.

With a big variety of designs, a large head range from about 30

m up to 700 m of head can be covered. The most powerful Francis turbines

have an output of up to 800 MW and use huge amounts of water.

KAPLAN TURBINE

For very low

heads and high flow rates a different type of turbine, the Kaplan or Propeller

turbine is usually employed. In the Kaplan turbine the water flows

through the propeller and sets the latter in rotation. In this turbine

the area through the water flows is as big as it can be – the entire area

swept by the blades. For this reason Kaplan turbines are suitable for very

large volume flows and they have become usual where the head is only a

few meters.

For very low

heads and high flow rates a different type of turbine, the Kaplan or Propeller

turbine is usually employed. In the Kaplan turbine the water flows

through the propeller and sets the latter in rotation. In this turbine

the area through the water flows is as big as it can be – the entire area

swept by the blades. For this reason Kaplan turbines are suitable for very

large volume flows and they have become usual where the head is only a

few meters.

|

The water enters the turbine laterally, is deflected by the guide

vanes, and flows axially through the propeller. For this reason,

these machines are referred to as axial-flow turbines. They have

the advantage over radial-flow turbines that it is technically simpler

to vary the angle of the blades when the power demand changes what improves

the efficiency of power production.

The flow rate of the water through the turbine can be controlled by varying the distance between the guide vanes; the pitch of the propeller blades must then also be appropriately adjusted. Each setting of the guide vanes corresponds to one particular setting of the propeller blades in order to obtain high efficiency. Important feature is that the blade speed is greater than the water speed – as much as twice as fast. This allows a rapid rate of rotation even with relatively low water speeds. Kaplan turbines come in a variety of designs. Their application is limited to heads from 1 m to about 30 m. Under such conditions, a relatively larger flow as compared to high head turbines is required for a given output. These turbines therefore are comparatively larger. |

CROSS-FLOW (BANKI) TURBINE

The concept of the Cross-Flow turbine -although much less

well-known than the three big names Pelton, Francis and Kaplan -is not

new. It was invented by an engineer named Michell who obtained a

patent for it in 1903. Quite independently, a Hungarian professor

with the name Donat Banki, re-invented the turbine again at the university

of Budapest. By 1920 it was quite well known in Europe, through a

series of publications. There is one single company who produces

this turbine since decades, the firm Ossberger in Bavaria, Germany. More

than 7000 such turbines are installed world-wide, most of them made

by Ossberger.

The main characteristic of the Cross-Flow turbine is the water jet

of rectangular cross-section which passes twice through the rotor

blades -arranged at the periphery of the cylindrical rotor - perpendicular

to the rotor shaft. The water flows through the blading first from

the periphery towards the centre, and then, after crossing the open space

inside the runner, from the inside outwards. Energy conversion takes

place twice; first when water falls down on the blades upon entry,

and then when water strikes the blades during exit from the runner.

The use of two working stages provides no particular advantage except

that it is a very effective and simple means of discharging the water

from the runner.

The machine is normally classified as an impulse turbine. This is

not strictly correct and is probably based on the fact that the original

design was a true constant-pressure turbine. A sufficiently large gap was

left between the nozzle and the runner, so that the jet entered the

runner without any static pressure. Modern designs are usually built with

a nozzle that covers a bigger arc of the runner periphery. With this

measure, unit flow is increased, permitting to keep turbine size

smaller. These designs work as impulse turbines only with small gate

opening, when the reduced flow does not completely fill the passages

between blades and the pressure inside the runner therefore is atmospheric.

With increased flow completely filling the passages between the blades,

there is a slight positive pressure; the turbine now works as a reaction

machine.

Cross-Flow turbines may be applied over a head range from less than

2 m to more than 100 m (Ossberger has supplied turbines for heads

up to 250 m). A large variety of flow rates may be accommodated with

a constant diameter runner, by varying the inlet and runner width.

This makes it possible to reduce the need for tooling, jigs and fixtures

in manufacture considerably. Ratios of rotor width/diameter, from

0.2 to 4.5 have been made. For wide rotors, supporting discs welded

to the shaft at equal intervals prevent the blades from bending.

A valuable feature of the Cross-Flow turbine is its relatively flat

efficiency curve, which Ossberger are further improving by using a divided

gate. This means that at reduced flow, efficiency is still quite

high, a consideration that may be more important than a higher optimum-point

efficiency of other turbines. Due to low price and good control these turbines

are, however, very successful in the area of small hydro-electric power

plants.

BIG OR SMALL HYDRO?

Hydro power plants range in capacity between few hundred watts to

more than 10.000 MW. Classification between big and small is quite common

where usually all power plants with capacity larger than 10 MW are considered

as big and all others as small. Classification among small hydro power

is also possible and terms like micro or nano hydro with capacity less

than 1 kW are also used in literature. Nevertheless it is worthwhile looking

at the specific characteristics and basic differences between big and small

power plants.

Big Hydropower

Big

hydropower stations are of a nature that requires a good infrastructure

such as roads (during construction) and access to a big market, resulting

in long high-tension grid systems and an extensive distribution system.

It serves a great number of individual consumers and supplies power

to electricity-intensive large industry.

Big

hydropower stations are of a nature that requires a good infrastructure

such as roads (during construction) and access to a big market, resulting

in long high-tension grid systems and an extensive distribution system.

It serves a great number of individual consumers and supplies power

to electricity-intensive large industry.

Big plants are usually owned and operated by big companies or state

enterprises. The skill requirements in management, administration, operation

and maintenance are considerable. Unit cost of energy generation is

relatively low. This is due to a decrease in specific investment cost

with rising plant size, and the probability of higher load factors with

a larger number of consumers. A problem is peak demand; big numbers

of consumers tend to have their maximum individual demand during

the same time-interval, which results in a largely uncontrollable

peak of demand that must be met with increased capacity, such as

standby installations and high cost pumped-storage.

|

From the engineering point of view, big hydro power calls for

sophisticated technology in manufacturing electro-mechanical equipment,

and high standards of feasibility studies, planning and civil construction

activities, because the risks involved are great. Long-term flow

data are a necessity and gestation periods are long. It is possible to

apply computer design technology and highly specialised fabrication

technology to achieve very high performance efficiencies that may

reach 96 % in the case of turbines. Needless to say, this process brings

about very high cost, which however may be justified because of the

large scale, where equipment cost is generally a relatively small

fraction of total cost.Big-scale hydropower stations require careful environmental

considerations. Artificial lakes may change an entire landscape and inundate

sizeable areas of arable land. Positive aspects are flood controlling

capability and the creation of new recreational sites (boating, fishing,

camping) although it is obvious that the benefits for recreation do not

rise in proportion with size.

THE CONTEXT FOR BIG HYDROPOWER STATIONS:

|

SMALL

HYDRO POWER PLANTS

Small and micro or nano

hydropower schemes combine the advantages of large hydro on the one

hand an decentralized power supply, on the other. They do not have many

of the disadvantages, such as costly transmissions and environmental

issues in the case of large hydro, and dependence on imported fuel

and the need for highly skilled maintenance in the case of fossil fuelled

plants. Moreover, the harnessing of small hydro-resources, being of a decentralised

nature, lends itself to decentralised utilization, local implementation

and management, making rural development possible mainly based on

self-reliance and the use of natural, local resources.

Small and micro or nano

hydropower schemes combine the advantages of large hydro on the one

hand an decentralized power supply, on the other. They do not have many

of the disadvantages, such as costly transmissions and environmental

issues in the case of large hydro, and dependence on imported fuel

and the need for highly skilled maintenance in the case of fossil fuelled

plants. Moreover, the harnessing of small hydro-resources, being of a decentralised

nature, lends itself to decentralised utilization, local implementation

and management, making rural development possible mainly based on

self-reliance and the use of natural, local resources.

There are in fact many thousands of small hydro plants in operation today all over the world. Modern hydraulic turbine technology is very highly developed with the a history of more than 150 years. Sophisticated design and manufacturing technology have evolved in industrialised countries over conventional technology the last 40 years. The aim is to achieve higher and higher conversion efficiencies, which makes sense in large schemes where 1 percent more or less may mean several MW of capacity. As far as costs are concerned, such sophisticated technology tends to be very expensive. Again, it is in the big schemes where economic viability is possible. Small installations for which the sophisticated technology of large hydro is often scaled down indiscriminately, have higher capital cost per unit of installed capacity. On the other hand environmental impacts due to small hydro stations are generally negligible or are controllable because of their size. Often they are non-existent.

Small hydro power plants are in large majority connected to the electricity grids. Most of them are of the “run-of-river” type, meaning simply that they do not have any sizeable reservoir (i.e. water not stored behind the dam) and produce electricity when the water provided by the river flow is available but generation ceases when the river dries-up and the flow falls below a predetermined amount. Power can be supplied by a small (or micro) hydro power plant in two ways. In a battery-based system, power is generated at a level equal to the average demand and stored in batteries. Batteries can supply power as needed at levels much higher than that generated and during times of low demand the excess can be stored. If enough energy is available from the water, an alternating current (AC) direct system can generate power. This system typically requires much higher power level than the battery-based system. Small hydropower in developing countries, on the other hand, implies decentralisation. Energy produced is usually supplied to relatively few consumers nearby, mostly with a low-tension distribution network only.

Small hydro schemes have different configurations according to the

head. High head schemes are typical of mountain areas, and due to the fact

that for the same power they need a lower flow, they are usually cheaper.

Low heads schemes are typical of the valleys and do not need feeder canal.

Of the numerous factors which affect the capital cost, site selection and

basic lay-out are among the first to be considered. Adequate head and flow

are necessary requirements for hydro generation.

Most hydro power systems require a pipeline to feed water to the

turbine. The exception is a propeller machine with an open intake. The

water must pass first through a simple filter to block debris that may

clog or damage the turbine. The intake is usually placed off to the side

of the main water flow to protect it from the direct force of the water

and debris during high flow.

High safety standards in construction works are often not necessary,

even the rupture of a small dam would not usually threaten human life,

and the risks are smaller anyway if initial costs are kept down. This makes

it possible to use mainly local materials and local construction

techniques, with a high degree of local labour participation.

Small hydro systems can require more maintenance than comparable

wind or photovoltaic systems. It is important to keep debris out

of the turbine. This is done by reliable screening and construction of

a settling basin. In the turbine itself, only the bearings and brushes

will require regular maintenance and replacement.

COST OF SHPP

Hydropower plants are characterised by high initial capital-investment

(according to World Bank total costs are between USD 1800 and

USD 8800 per kW for heads from 2,3 to 13,5 m and USD 1000 to

USD 3000 for heads between 27 and 350 meters.) and low operation

and maintenance cost. The investment costs include:

![]() Construction

(dam, channel, machine house),

Construction

(dam, channel, machine house),

![]() Parts for electricity

generation (turbine, generator, transformer, power lines),

Parts for electricity

generation (turbine, generator, transformer, power lines),

![]() Other

(engineering, ground property, commissioning).

Other

(engineering, ground property, commissioning).

Usually equipment for low head and low output becomes very costly

and equipment cost ranges from 40 to 50 % of total cost in conventional

hydro installations. As far as costs of civil construction-components are

concerned, no standard cost unit can be given. Dams, canals and intakes

will obviously cost a very different share of the total for different

sites. Much depends on the topography and the geology, and also on

the construction method applied and the materials used. Just to mention

some examples the total cost of new small hydro power plants in Germany

was 10-16 DM/W (5-9 ECU/W) and are divided in most cases 35% (construction)

- 50% (electricity parts) - 15% (other). There are of course some differences

between countries e.g. costs of 8 kW turbine (Banki type with regulation)

in Czech republic is 4000 USD , equivalent to 3500 ECU or 0,45 ECU/W.

The high investment costs is the largest barrier in development

of small hydro power schemes. Despite this obstacle and long pay-back times

(7-10 years in some countries e.g. Slovakia) small hydro power plants are

often cost-effective because of their long life-time (often more than 70

years) and low maintenance costs. As a general rule, total costs of operation

and maintenance without major replacements account for approximately 3

to 4% of capital costs for small and micro-hydropower installations.

THE CONTEXT FOR SMALL HYDROPOWER STATIONS

![]() Decentralised,

small power demand; small industry, individual farms and enterprises,

rural communities.

Decentralised,

small power demand; small industry, individual farms and enterprises,

rural communities.

![]() Low tension

distribution networks and eventually sub-regional micro-grid systems.

Low tension

distribution networks and eventually sub-regional micro-grid systems.

![]() Individual,

co-operative or communal ownership with semi-skilled labour requirements

and co-operative administration.

Individual,

co-operative or communal ownership with semi-skilled labour requirements

and co-operative administration.

![]() Short gestation

period with local materials and skills applicable depending on potential,

it can make a considerable impact on the quality of rural life.

Short gestation

period with local materials and skills applicable depending on potential,

it can make a considerable impact on the quality of rural life.

![]() Its flexibility

regarding adaptation to quick load variations makes it a favoured component

in any integrated power system.

Its flexibility

regarding adaptation to quick load variations makes it a favoured component

in any integrated power system.

![]() Plants can

last for very long time. Some are more than 70 years old and still in operation.

Plants commissioned recently may show even longer life span and thus can

serve consumers over several generations without polluting the atmosphere.

Plants can

last for very long time. Some are more than 70 years old and still in operation.

Plants commissioned recently may show even longer life span and thus can

serve consumers over several generations without polluting the atmosphere.

![]() Investment

in small hydro power have proved to be safe and secure over several decades.

Investment

in small hydro power have proved to be safe and secure over several decades.

![]()

SMALL HYDRO POWER PLANTS FOR

DEVELOPING COUNTRIES

In

developing countries the domain where small hydropower can potentially

have an important impact on development is in domestic lighting and

in providing stationary motive power for such diverse productive

uses as water-pumping, wood and metal working, grain milling, textile

fibre spinning and weaving. While much of the discussion is concerned

with the generation of electricity, it must be recognised that the

same source of power can perform mechanical tasks directly via gears

and belt drives, very often more economically.

In

developing countries the domain where small hydropower can potentially

have an important impact on development is in domestic lighting and

in providing stationary motive power for such diverse productive

uses as water-pumping, wood and metal working, grain milling, textile

fibre spinning and weaving. While much of the discussion is concerned

with the generation of electricity, it must be recognised that the

same source of power can perform mechanical tasks directly via gears

and belt drives, very often more economically.

Emphasis is on the use of currently available know-how, using

simple equipment that can be made locally, and the use of local construction

materials and techniques. The aim is to reduce capital costs as far

as possible. Rather than scaling down large-scale technology, this

may lead to a more appropriate upgrading of local technology for

larger schemes at a later stage.

CHINA

The construction of small hydropower stations has been a very

meaningful in the past 25 years. Besides the development of large resources,

much emphasis was given to small-scale developments resulting in an estimated

100.000 stations around the vast countryside with installed capacity approaching

10.000 MW.

The first large-scale campaign to establish many small waterworks

started in 1956. An ambitious plan called for the construction of 1000

small stations of a multi-purpose character, combining irrigation,

flood control and power generation, in one year, reaching a total capacity

of 30 MW. Although industrial capability permitted construction of large

turbines, and the range under which small hydropower falls in China was

extended to 12 MW, this indicates that construction of very small units

continued. In fact, a range of miniature turbine-generators with outputs

from 0,6 to 12 kW was developed, suitable for scattered mountain

villages with small hydropower resources.

The development activities in this field were entirely relying on

local resources -materials, skill and labour - and the results achieved

are from this perspective even more impressive. Hydropower development

in China faces some major natural obstacles. The regional distribution

of resources is very uneven and concentrated in regions that are thinly

populated. Flow variations in many rivers are considerable. The maximum

recorded flood flow in the Huang Ho river was 88 times larger than the

minimum discharge and in smaller rivers this ratio is likely to be

much higher.

MICRO

HYDRO SYSTEMS

Microhydro

systems are defined as hydroelectric systems that produce less than 1000

Watts. At the high end, microhydro systems produce enough power to run

three electrically efficient households. No other form of renewable energy

is so reliable or powerful for what it costs. Micro hydro system means

that the site has either very little fall or very small flow of water,

but probably not both. At sites with lower flow rates, systems are usually

tied to a battery bank and configured to produce direct current. With larger

hydro resources, systems may be configured to produce alternating current

without the use of a battery bank. These systems must be able to directly

power peak loads. In some case excess power produced is transferred to

an alternate load such as a hot water heater.

Microhydro

systems are defined as hydroelectric systems that produce less than 1000

Watts. At the high end, microhydro systems produce enough power to run

three electrically efficient households. No other form of renewable energy

is so reliable or powerful for what it costs. Micro hydro system means

that the site has either very little fall or very small flow of water,

but probably not both. At sites with lower flow rates, systems are usually

tied to a battery bank and configured to produce direct current. With larger

hydro resources, systems may be configured to produce alternating current

without the use of a battery bank. These systems must be able to directly

power peak loads. In some case excess power produced is transferred to

an alternate load such as a hot water heater.

A hydropower

turbine appropriate for household use can be bought for about USD 1000.

These simple units are about the size of a breadbox and use a rewired automobile

alternator to produce direct current. The direct current is used to charge

batteries, then converted to AC power with an inverter.

A hydropower

turbine appropriate for household use can be bought for about USD 1000.

These simple units are about the size of a breadbox and use a rewired automobile

alternator to produce direct current. The direct current is used to charge

batteries, then converted to AC power with an inverter.

A typical micro hydro installation diverts a small portion of stream flow across a screen into a water storage e.g. 200 litre drum. The drum acts as a settling basin and the screen collects debris from the water which may clog the intake to the turbine. The water flows from the drum to the turbine through PVC piping (usually 5 to 10 centimetres in diameter), and then returns to the stream. Additional costs for piping, controls, batteries, and wiring vary depending on the particular application, but range from USD 1000 to USD 5000.

Micro hydro

turbines come in two basic forms. One uses an alternator, just like an

automobile. The other (nano hydro systems) uses a permanent magnet (permag)

generator/motor. The alternator based machines are for larger systems producing

from 100 to 1000 watts, while the permag units are best suited to systems

producing under 80 Watts.

Micro hydro

turbines come in two basic forms. One uses an alternator, just like an

automobile. The other (nano hydro systems) uses a permanent magnet (permag)

generator/motor. The alternator based machines are for larger systems producing

from 100 to 1000 watts, while the permag units are best suited to systems

producing under 80 Watts.

Larger systems use shunt diversion for regulation. This prevents

overspeeding of the turbine and premature wear of parts. Smaller systems

use regulation schemes that unload the alternator when power is not needed.

In all cases, these controls need to be user adjustable. Micro hydro systems

are easy to fit with batteries. The turbine produces constant power all

the time. The battery acts as a “flywheel” to smooth out the inevitable

peaks of consumption. Micro hydros refill the batteries almost immediately

after even a little power is consumed from the battery. These systems are

“shallow-cycling” and ordinary batteries will last a long time. Usually

spending money on good pipe and an efficient turbine is more effective

than spending it on batteries. In a microhydro system the length and diameter

of the pipe must be specified to suit the situation and the turbine. Using

long runs of small diameter pipe will make even the finest turbine ineffective.

NANOHYDRO - PERMAG

|

What sets nano hydro systems apart from other hydro generators is the use of permanent magnet generators for the power source. The advantage to this is that no power is fed back into the machine to electrically generate a magnetic field, as is the case with most alternators, so all of what is produced will feed the batteries. The disadvantage of a permag set-up is that the maximum output is limited by the inherent strength of the magnets. Normally that's not a problem in a nano hydro situation because usually flow and head of water are too small for a larger, more powerful system anyway. |

BATTERY-BASED SYSTEMS

Most micro and nano hydro systems are battery-based. They require

far less water than AC systems and are usually less expensive. Because

the energy is stored in batteries, the generator can be shut down without

interrupting the power delivered to the loads. Since only the average load

needs to be generated in this system, the pipeline, turbine, generator

and other components can be much smaller than those in AC system. For conversion

of DC battery power to AC output (type of power needed by most of home

appliances) inverters are used. The input voltage to the batteries in battery-based

system usually ranges from 12 to 48 Volts DC. If the transmission distance

is not long then 12 V system is used. For longer transmission distances

higher voltage is used.

![]()

AC SYSTEMS

Alternating current (AC) hydro power systems are those used by utilities,

but it can also be used on a home power scale under the appropriate conditions.

In home power scale system power is not sent to the utility grid, but is

directly used by a homeowners appliances (load). AC system does not need

batteries. This means that the generator must be capable of supplying the

continuous demand, including the peak load. The most difficult load is

the short-lasting power surge drawn by motors in refrigerators, washing

machines and some other appliances. Usually in typical AC system, an electronic

controller is keeping voltage and frequency within prescribed limits. The

output from hydro power plan can not be stored and any unused power is

sent to a “shunt” load, which can be e.g. a hot water heater. There is

almost always enough excess power from this type of system to heat domestic

hot water and provide space heating as well.

PUMP AS TURBINE

High costs of equipment and civil works, or more generally, the

capital-intensive nature of small hydropower plants, has long been a major

constraint. However, in many situations it is necessary not only to achieve

a better relation of costs compared to other energies, but to reduce them

in absolute terms. This is possible to some degree by standardising equipment,

but the scope for using such standardised equipment remains limited since

no two sites are exactly the same. Efforts at cost reduction through indigenous

manufacture are more promising, largely due to much lower labour costs.

To make this possible, standards of design, performance and sometimes reliability

must be lowered and all unnecessary sophistication avoided. The same is

true in civil construction work, where local materials and techniques should

be used to the largest possible extent.

In developing countries and especially in rural areas, it is generally recognized that small hydropower may play a significant role. However, high initial investment costs of small hydropower plants have restricted rapid development of this energy potential in many countries. The use of standard pumps as turbines (PAT) may often be an alternative with a considerable economic advantage and might therefore contribute to a broader application of micro-hydropower. Direct drive of machinery, electricity generation (in parallel to a large grid or isolated) or combinations of these are possible just as with a conventional turbine. The only difference is that a PAT cannot make use of the available water as efficiently as a turbine due to its lack of hydraulic controls.

FIELDS OF APPLICATION OF PUMPS

USED AS TURBINES

Pumps (rotational fluid machines) are completely reversible and

can run effectively as a turbine. Standard pumps not intentionally designed

to operate as turbines are now more and more used in small and micro-hydropower

schemes due to their advantages mentioned above. However, performance in

both modes are not identical although the theory of ideal fluids would

predict the same. Without exception, the optimum flow and head in the turbine

mode is greater than in pumping mode. The main reason for this difference

is related to the hydraulic losses of the machine.

Applications of PAT range from direct drive of machinery in agro-processing

factories and small industries (flour mills, oil expellers, rice hullers,

saw mills, wood and metal workshops) to electricity generation both in

stand-alone and grid-linked stations.

In most instances, no design changes or modifications need to be

made for a pump operating as a turbine provided that selection has taken

into account the higher operating head and power output of the machine

in turbine mode and consequently, nominal turbine speed has been taken

well below maximum permissible pump speed. However, a design review is

also required to check any adverse effects occurring from the reverse rotation

in turbine mode.

Advantages of PAT

![]() the investment

costs of PATs may be less than 50% of those of a comparable turbine (especially

for small units below 50 kW). This might be an important issue for projects

with limited budgets and loan possibilities

the investment

costs of PATs may be less than 50% of those of a comparable turbine (especially

for small units below 50 kW). This might be an important issue for projects

with limited budgets and loan possibilities

![]() construction:

the absence of a flow control device, usually felt as a drawback, is at

the same time an advantage since the pump construction is usually simple

and sturdy

construction:

the absence of a flow control device, usually felt as a drawback, is at

the same time an advantage since the pump construction is usually simple

and sturdy

![]() availability:

due to their widespread application (irrigation, industry, water supply),

standard pumps are readily available (short delivery times) and manufacturers

and their representatives are world-wide present

availability:

due to their widespread application (irrigation, industry, water supply),

standard pumps are readily available (short delivery times) and manufacturers

and their representatives are world-wide present

![]() spare parts:

spare parts are readily available since major pump manufacturers offer

after- sales services almost throughout the world

spare parts:

spare parts are readily available since major pump manufacturers offer

after- sales services almost throughout the world

![]() maintenance:

no special equipment and skills are required.

maintenance:

no special equipment and skills are required.

Disadvantages

![]() No hydraulic

control device: therefore, a control valve must be incorporated in the

penstock line (additional costs) to start and stop the PAT. If the valve

is used to accommodate to seasonal variations of flow, the hydraulic losses

of the installation will increase sharply.

No hydraulic

control device: therefore, a control valve must be incorporated in the

penstock line (additional costs) to start and stop the PAT. If the valve

is used to accommodate to seasonal variations of flow, the hydraulic losses

of the installation will increase sharply.

![]() Lower efficiency

at part load: a conventional turbine has an effective hydraulic control

(adjustable guide vanes, nozzles or runner blades) to adjust the machine

to the available flow or the required output. If PATs are operated at other

than the design flow, i.e. below their best efficiency point a relatively

rapid drop of efficiency will occur.

Lower efficiency

at part load: a conventional turbine has an effective hydraulic control

(adjustable guide vanes, nozzles or runner blades) to adjust the machine

to the available flow or the required output. If PATs are operated at other

than the design flow, i.e. below their best efficiency point a relatively

rapid drop of efficiency will occur.

The disadvantages of PATs can be reduced to a minimum if the PAT

is very carefully selected and only applied where justified. Poor performance

due to an inappropriately selected machine or application will lead to

a reduction of gains. Summed up over the entire lifetime of the machine,

this reduced output might by far offset the cost advantage of the PAT (lower

investment costs) in comparison to a conventional turbine.

![]()

DIFFERENCES BETWEEN PUMPS

AND TURBINES

Pumps are usually operated with constant speed, head and flow. A

pump is therefore designed for one particular of operation (duty point)

and does not require a regulating device (guide vane). Ideally, the duty

point coincides with the maximum efficiency of the pump.

Turbines operate under variable head and flow conditions.

In an small hydro power plant, flow must be adjustable to either accommodate

to seasonal variations of the available water or to adjust power output

according to the demand of the consumers. Adjustable guide vanes and/or

runner blades (or nozzles controlled by a streamlined valve) regulate the

flow.

TYPE OF PUMP TO BE USED AND EFFICIENCY

IN TURBINE MODE

Virtually any type of pump may be used as turbine. However, the

main advantage of a PAT, i.e. lower costs than a conventional turbine,

is very pronounced for standard centrifugal and mixed flow pumps whereas

axial flow pumps are less advantageous in that respect. The vast field

of different pump designs and power ranges provides a suitable PAT for

almost any application with heads from about 10 m up to several hundred

meters. Large flows may be accommodated with double-flow pumps. Even submersible

pumps may be used as PATs which, when integrated in the water course or

pipe system, are completely hidden away underground, an important factor

for the conservation of the environment. Efficiencies of pumps used as

turbines may be the same as in pump mode but are more often several percent

(3 - 5%) lower.

Direct drive of machinery, electricity generation (in parallel to a large grid or isolated system) or combinations of these are possible just as with a conventional turbine. Although the PATs cover a wide range of the small hydropower domain, they cannot replace conventional turbines everywhere. Since PATs have no hydraulic control device such as guide vanes, they are usually unsuitable to accommodate variable flow conditions. Throttling flow by means of a control valve in the penstock is inefficient and only applicable over a small range.

The lack of a hydraulic control device of a PAT has long been seen as a disadvantage also in terms of constancy of PAT speed under variable load. Grid-linked electricity generation or direct drive of machinery are either constant load applications or do not require precise speed control. These applications are therefore very suitable for PATs. Stand alone electricity generation on the other hand requires some form of governing to keep voltage and frequency within acceptable limits under changing load. The use of PATs in free-standing electricity generation is, however, not excluded due to the recent development of electronic load controllers which provide effective governing in conjunction with both induction and synchronous generators. Electronic load controllers keep the load on the PAT constant by switching in ballast loads whenever the electricity demand of the consumers drops.

HYDRO RAM PUMP

Hydro ram is not an animal but a self-driven pump first installed

at the turn of the century when they were popular with farmers who had

natural water courses on their land. With the coming of grid electricity

and mains water, many rams were left to rot and rust in the post-war period.

Nevertheless this device is a useful source of cheap energy even today.

Ram pumps do not produce electricity but the mechanical work for pumping

water to higher elevations. They use a downhill water pressure to pump

a portion of that water higher uphill to a holding tank. No other

source of power is needed. The hydro rams are complete in themselves and

designed to work with the minimum of attention, and to suit all the ordinary

conditions.

The hydro ram has proved to be one of the most reliable devices

used for water pumping. Many over 100 years old are still in use, and it

remains one of the few really practical and efficient uses of renewable