|

BIOMASS |

Biomass

as the solar energy stored in chemical form in plant and animal

materials is

among the most precious and versatile resources on earth. It provides

not only

food but also energy, building materials, paper, fabrics, medicines and

chemicals. Biomass has been used for energy purposes ever since man

discovered

fire. Today, biomass fuels can be utilised for tasks ranging from

heating the

house, producing electicity or fuelling a car.iomass as

the solar energy stored in chemical form in plant and animal materials

is among

the most precious and versatile resources on earth. It provides not

only food

but also energy, building materials, paper, fabrics, medicines and

chemicals.

Biomass has been used for energy purposes ever since man discovered

fire. Today,

biomass fuels can be utilised for tasks ranging from heating the house

to

fuelling a car and running a computer.

Biomass

as the solar energy stored in chemical form in plant and animal

materials is

among the most precious and versatile resources on earth. It provides

not only

food but also energy, building materials, paper, fabrics, medicines and

chemicals. Biomass has been used for energy purposes ever since man

discovered

fire. Today, biomass fuels can be utilised for tasks ranging from

heating the

house, producing electicity or fuelling a car.iomass as

the solar energy stored in chemical form in plant and animal materials

is among

the most precious and versatile resources on earth. It provides not

only food

but also energy, building materials, paper, fabrics, medicines and

chemicals.

Biomass has been used for energy purposes ever since man discovered

fire. Today,

biomass fuels can be utilised for tasks ranging from heating the house

to

fuelling a car and running a computer.

THE CHEMICAL COMPOSITION OF BIOMASS

|

The chemical composition of biomass varies among species, but plants consists of about 25% lignin and 75% carbohydrates or sugars . The carbohydrate fraction consists of many sugar molecules linked together in long chains or polymers. Two larger carbohydrate categories that have significant value are cellulose and hemicellulose. The lignin fraction consists of non-sugar type molecules. Nature uses the long cellulose polymers to build the fibers that give a plant its strength. The lignin fraction acts like a “glue” that holds the cellulose fibers together. |

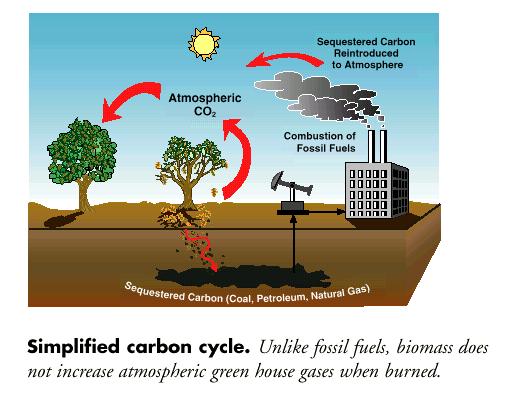

In addition to the

aesthetic value of the planet’s flora, biomass represents a useful and

valuable

resource to man. For millennia humans have exploited the solar energy

stored in

the chemical bonds by burning biomass as fuel and eating plants for the

nutritional energy of their sugar and starch content. More recently, in

the

last few hundred years, humans have exploited fossilized biomass in the

form of

coal. This fossil fuel is the result of very slow chemical

transformations that

convert the sugar polymer fraction into a chemical composition that

resembles

the lignin fraction. Thus, the additional chemical bonds in coal

represent a

more concentrated source of energy as fuel. All of the fossil fuels we

consume

- coal, oil and natural gas - are simply ancient biomass. Over millions

of

years, the earth has buried ages-old plant material and converted it

into these

valuable fuels. But while fossil fuels contain the same constituents -

hydrogen

and carbon - as those found in fresh biomass, they are not considered

renewable

because they take such a long time to create. Environmental impacts pose another significant

distinction between biomass

and fossil fuels. When a plant decays, it releases most of its chemical

matter

back into the atmosphere. In contrast, fossil fuels are locked away

deep in the

ground and do not affect the earth’s atmosphere unless they are burned.

Wood may be the

best-known example of biomass. When burned, the wood releases the

energy the

tree captured from the sun’s rays. But wood is just one example of

biomass.

Various biomass resources such as agricultural residues (e.g. bagasse

from

sugarcane, corn fiber, straw and even nutshells), wood waste (e.g.

sawdust,

timber slash, and mill scrap), the paper trash and urban yard clippings

in

municipal waste, energy crops (fast growing trees like poplars,

willows, and

grasses like switchgrass or elephant grass), and the methane captured

from

landfills, municipal waste water treatment, and manure from cattle or

poultry,

can also be used.

Biomass is considered to

be one of the key renewable resources of the future at both small- and

large-scale levels. It already supplies 14 % of the world’s primary

energy

consumption. But for three quarters of the world’s population living in

developing countries biomass is the most important source of energy.

With

increases in population and per capita demand, and depletion of

fossil-fuel

resources, the demand for biomass is expected to increase rapidly in

developing

countries. On average, biomass produces 38 % of the primary energy in

developing countries (90 % in some countries). Biomass is likely to

remain an

important global source in developing countries well into the next

century.

Utilisation of biomass as the energy source in the world.

Even in developed

countries, biomass is being increasingly used. A number of developed

countries

use this source quite substantially, e.g. in Sweden and Austria 15 % of

their

primary energy consumption is covered by biomass. Sweden has plans to

increase

further use of biomass as it phases down nuclear and fossil-fuel

plants.

|

In the USA , which derives 4 % of its total energy from biomass (nearly as much as it derives from nuclear power), now more than 9000 MW electrical power is installed in facilities firing biomass. But biomass could easily supply more than 20 % of US energy consumption. In other words, due to the available land and agricultural infrastructure this country has, biomass could, sustainably, replace all of the power nuclear plants generate without a major impact on food prices. Furthermore, biomass used to produce ethanol could reduce also oil imports up to 50%. |

BIOMASS

-

SOME BASIC DATA ![]()

![]() Total world biomass content - 1880 billion tonnes

Total world biomass content - 1880 billion tonnes

![]() Total

mass in tropical forests -1030 billion tonnes

Total

mass in tropical forests -1030 billion tonnes

![]() Total

mass in temperate

forests, savanna and tundra - 790 billion tonnes

Total

mass in temperate

forests, savanna and tundra - 790 billion tonnes

![]() Total

marine biomass content - 4 billion tonnes

Total

marine biomass content - 4 billion tonnes

![]() Per capita terrestrial biomass - 310 tonnes

Per capita terrestrial biomass - 310 tonnes

![]() Energy

stored in terrestrial biomass - 25 000 EJ

Energy

stored in terrestrial biomass - 25 000 EJ

![]() Net

annual

production of of

terrestrial biomass - 400 billion tonnes

Net

annual

production of of

terrestrial biomass - 400 billion tonnes

![]() Rate of

energy

storage by land biomass - 3000 EJ/y (95 TW)

Rate of

energy

storage by land biomass - 3000 EJ/y (95 TW)

![]() Total

consumption

of all forms of energy - 400 EJ/y (12 TW)

Total

consumption

of all forms of energy - 400 EJ/y (12 TW)

![]() Biomass

energy

consumption - 55 EJ/y ( 1. 7 TW)

Biomass

energy

consumption - 55 EJ/y ( 1. 7 TW)

often used against

biomass, particularly against large-scale fuel production, is that it

could

divert agricultural production away from food crops, especially in

developing

countries. The basic argument is that energy-crop programmes compete

with food

crops in a number of ways (agricultural, rural investment,

infrastructure,

water, fertilizers, skilled labour etc.) and thus cause food shortages

and

price increases. However, this so-called “food versus fuel” controversy

appears

to have been exaggerated in many cases. The subject is far more complex

than

has generally been presented since agricultural and export policy and

the

politics of food availability are factors of far greater importance.

The argument

should be analysed against the background of the world’s (or an

individual

country’s or region’s) real food situation of food supply and demand

(ever-increasing food surpluses in most industrialized and a number of

developing countries), the use of food as animal feed, the

under-utilized

agricultural production potential, the increased potential for

agricultural

productivity, and the advantages and disadvantages of producing

biofuels.

LAND AVAILABILITY

Biomass differs

fundamentally from other forms of fuels since it requires land to grow

on and

is therefore subject to the range of independent factors which govern

how, and

by whom, that land should be used. There are basically two main

approaches to

deciding on land use for biomass. The “technocratic” approach starts

from a

need for, then identifies a biological source, the site to grow it, and

then

considers the possible environmental impacts. This approach generally

had

ignored many of the local and more remote side-effects of biomass

plantations

and also ignored the expertise of the local farmers who know the local

conditions. This has resulted in many biomass project failures in the

past. The

“multi-uses” approach asks how land can best be used for sustainable

development, and considers what mixture of land use and cropping

patterns will

make optimum use of a particular plot of land to meet multiple

objectives of

food, fuel, fodder, societal needs etc. This requires a full

understanding of

the complexity of land use.

Generally

it can be said that biomass productivity can be improved since in

many place of the world is low, being much less than 5 t/ha/yr. for

woody

species without good management. Increased productivity is the key to

both

providing competitive costs and better utilisation of available land.

Advances

have included the identification of fast-growing species, breeding

successes

and multiple species opportunities, new physiological knowledge of

plant growth

processes, and manipulation of plants through biotechnology

applications, which

could raise productivity 5 to 10 times over natural growth rates in

plants or

trees.

It is now possible with good management, research, and planting

of selected

species and clones on appropriate soils to obtain 10 to 15 t/ha/yr. in

temperate areas and 15 to 25 t/ha/yr. in tropical countries. Record

yields of

40 t/ha/yr. (dry weight) have been obtained with eucalyptus in Brazil

and

Ethiopia. High yields are also feasible with herbaceous (non-woody)

crops where

the agro-ecological conditions are suitable. For example, in Brazil,

the

average yield of sugarcane has risen from 47 to 65 t/ha (harvested

weight) over

the last 15 years while over 100t/ha/yr are common in a number of areas

such as

Hawaii, South Africa, and Queensland in Australia. It should be

possible with

various types of biomass production to emulate the three-fold increase

in grain

yields which have been achieved over the past 45 years although this

would

require the same high levels of inputs and infrastructure development.

However,

in trials in Hawaii, yields of 25 t/ha/yr. have been achieved without

nitrogen

fertilizers when eucalyptus is interplanted with nitrogen fixing

Albizia trees.

ENERGY VALUE

Biomass (when considering

its energy potential) refers to all forms of plant-derived material

that can be

used for energy: wood, herbaceous plants, crop and forest residues,

animal

wastes etc. Because biomass is a solid fuel it can be compared to coal.

On a

dry-weight basis, heating values range from 17,5 GJ per tonne for

various

herbaceous crops like wheat straw, sugarcane bagasse to about 20

GJ/tonne for

wood. The corresponding values for bituminous coals and lignite are 30

GJ/tonne

and 20 GJ/tonne respectively (see tables bellow). At the time of its

harvest

biomass contains considerable amount of moisture, ranging from 8 to 20

% for

wheat straw, to 30 to 60 % for woods, to 75 to 90 % for animal manure,

and to

95 % for water hyacinth. In contrast the moisture content of the most

bituminous coals ranges from 2 to 12 %. Thus the energy density for the

biomass

at the point of production are lower than those for coal. On the other

side

chemical attributes make it superior in many ways. The ash content of

biomass

is much lower than for coals, and the ash is generally free of the

toxic metals

and other contaminants and can be used as soil fertiliser.

Energy contents comparison table.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BENEFITS OF BIOMASS AS

ENERGY SOURCE

Rural economic

development in both developed and developing countries is one of the

major

benefits of biomass. Increase in farm income and market

diversification,

reduction of agricultural commodity surpluses and derived support

payments,

enhancement of international competitiveness, revitalization of

retarded rural

economies, reduction of negative environmental impacts are most

important issues

related to utilisation of biomass as energy source. The new incomes for

farmers

and rural population improve the material welfare of rural communities

and this

might result in a further activation of the local economy. In the end,

this

will mean a reduction in the emigration rates to urban environments,

which is

very important in many areas of the world.

The number of jobs

created (for production, harvesting and use) and the industrial growth

(from

developing conversion facilities for fuel, industrial feedstocks, and

power)

would be enormous. For instance, the U.S. Department of Agriculture

estimates

that 17,000 jobs are created per every million of gallons of ethanol

produced,

and the Electric Power Research Institute has estimated that producing

5 quadrillion

Btu’s (British Thermal Units) of electricity on 50 million acres of

land would

increase overall farm income by $12 billion annually (the U.S. consumes

about

90 quadrillion Btu’s annually). By providing farmers with stable

income,

these new markets diversify and strengthen the local economy by keeping

income

recycling through the community.

Improvement in

agricultural resource utilisation has been frequently proposed in EU.

The

development of alternative markets for agricultural products might

result in

more productive uses of the cropland, currently under-utilised in many

EU

countries. In 2001, the EU

planted 128 million ha of land to crops. Approximately 0,8 million ha

were

removed from production under the set aside program. A much greater

amount is

planned to remain idled in future. It is clear that reorientation of

some of

these lands to non-food utilisation (like biomass for energy) might

avoid

misallocation of agricultural resources. European agriculture relies on

the

production of a limited number of crops, mainly used for human and

livestock

food, many of which are at present on surplus production. Reduced

prices

have resulted in low and variable income for many EU farmers. The

cultivation

of energy crops could reduce surpluses. New energy crops may be more

economically competitive than crops in surplus production.

ENVIRONMENTAL BENEFITS

The use of biomass

energy has many unique qualities that provide environmental benefits.

It can

help mitigate climate change, reduce acid rain, soil erosion, water

pollution

and pressure on landfills, provide wildlife habitat, and help maintain

forest

health through better management.

CLIMATE CHANGE

Climate change is a

growing concern world-wide. Human activity, primarily through the

combustion of fossil fuels, has released hundreds of millions of tons

of

so-called ‘greenhouse gases’ (GHGs) into the atmosphere. GHGs include

such

gases as carbon dioxide (CO2) and methane (CH4). The concern is

that all

of the greenhouse gases in the atmosphere will change the Earth’s

climate,

disrupting the entire biosphere which currently supports life as we

know

it. Biomass energy technologies can help minimize this

concern.

Although both methane and carbon dioxide pose significant threats, CH4

is 20

times more potent (though shorter-lived in the atmosphere) than CO2.

Capturing

methane from landfills, wastewater treatment, and manure lagoons

prevents the

methane from being vented to the atmosphere and allows the energy to be

used to

generate electricity or power motor vehicles. All crops,

including

biomass energy crops, sequester carbon in the plant and roots while

they grow,

providing a carbon sink. In other words, the carbon dioxide released

while

burning biomass is absorbed by the next crop growing. This is called a

closed

carbon cycle. In fact, the amount of carbon sequestered may be

greater

than that released by combustion because most energy crops are

perennials, they

are harvested by cutting rather than uprooting. Thus the roots

remain to

stabilize the soil, sequester carbon and to regenerate the following

year.

ACID RAIN

Acid rain is caused

primarily by the release of sulphur and nitrogen oxides from the

combustion of

fuels like coal. Acid rain has been implicated in the killing of

lakes,

as well as impacting humans and wildlife in other ways. Since

biomass has

practically no sulphur content, and easily mixes with coal, “co-firing”

is a

very simple way of reducing sulphur emissions and thus, reduce acid

rain.

“Co-firing” refers to burning biomass jointly with coal in a

traditionally

coal-fired power plant or heating plant.

SOIL EROSION & WATER

POLLUTION

Biomass crops can reduce

water pollution in a number of ways. Energy crops can be grown on more

marginal

lands, in floodplains, and in between annual crops areas. In all these

cases,

the crops stabilize the soil, thus reducing soil erosion. They also

reduce

nutrient run-off, which protects aquatic ecosystems. Their shade can

even

enhance the habitat for numerous aquatic organisms like fish.

Furthermore,

because energy crops tend to be perennials, they do not have to be

planted

every year. Since farm machinery spends less time going over the field,

less

soil compaction and soil disruption takes place. Another way

biomass

energy can reduce water pollution is by capturing the methane, through

anaerobic digestion, from manure lagoons on cattle, hog and poultry

farms. These enormous lagoons have been responsible for polluting

rivers and

streams across the country. By utilizing anaerobic digesters, the

farmers can

reduce odour, capture the methane for energy, and create either liquid

or

semi-solid soil fertilisers which can be used on-site or sold.

![]()

BIOMASS

FUELS

Plants are the most

common source of biomass. They have been used in the form of wood, peat

and

straw for thousands of years. Today the western world is far less

reliant on

this energy fuel. This is because of the general acceptance that coal,

oil,

natural gas and electricity are cleaner, more efficient and more in

keeping

with modernisation and technology. However this is not really the right

impression. Plants can either be specially grown for energy production,

or they

can be harvested from the natural environment. Plantations tend to use

breeds

of plant that are to produce a lot of biomass quickly in a sustainable

fashion.

These could be trees (e.g. willows or Eucalyptus) or other high growth

rate

plants (such as sugar cane or maize or soybean).

WOOD RESIDUES

Wood can be, and usually

is, removed sustainably from existing forests world-wide by using

methods such

as coppicing. It is difficult to estimate the mean annual

increment

(growth) of the world’s forests. One rough estimate is 12,5 billion

m3/yr. with

an content of 182 EJ equivalent to 1,3 times the total world coal

consumption.

The estimated global average annual wood harvests is around 3,4 billion

m3/yr.

(equivalent to 40 EJ/yr.), so some of the unused increment could be

recovered

for energy purposes while maintaining or possibly even enhancing the

productivity of forests.

|

Operations

such as

thinning of plantations and trimming of felled trees generate large

volumes of

forestry residues. At present these are often left to rot on site -

even in

countries with fuelwood shortages. They can be collected, dried and

used as

fuel by nearby rural industry and domestic consumers, but their bulk

and high

water content makes transporting them for wider use uneconomic. In

developing

countries where charcoal is an important fuel, on-site kilns can reduce

transport costs. Mechanical harvesters and chippers have been developed

in Europe

and North America over the last 15 years to produce uniform 30-40 mm

wood chips

which can be handled, dried and burned easily in chip-fired boilers.

|

The use of forest

residues to produce hot water or steam for heating and/or power

generation is

now a growing business in many countries. American electricity

utilities have

more than 9 000 MW (output of 9 nuclear power plants) of biomass-fired

generating plant on line, much of it constructed in the last ten years.

Austria

has about 1250 MW of wood-fired heating capacity in the form of

domestic stoves

and district heating plant, burning waste wood, bark and wood chips.

Most of

these district heating systems are of 1-2 MW capacity, with a few

larger units

(around 15 MW) and a number of small-scale CHP systems.

Timber processing is a

further source of wood residues. Dry sawdust and waste produced during

the

processing of cut timber make very good fuel. The British furniture

industry is

estimated to use 35 000 tonnes of such residues a year, one third of

its production,

providing 0,5 PJ of space and water heating and process heat. In

Sweden, where

biomass already provides nearly 15% of primary energy, forestry

residues and

wood industries contribute over 200 PJ/yr., mainly as fuel for CHP

plant.

AGRICULTURAL RESIDUES

Agricultural waste is a

potentially huge source of biomass. Crop and animal wastes provide

significant

amounts of energy coming second only to wood as the dominant biomass

fuel

world-wide. Waste from agriculture includes: the portions of crop

plants discarded

like straw, whether damaged or surplus supplies, and animal dung. It

was estimated,

for example, that 110 million tonnes of dung and crop residues is used as fuel in India, compared with 133 Mt of

wood, and in China the mass of available agricultural residues has been

estimated at 2,2 times the mass of wood fuel.

Every year, millions tonnes of straw are produced world-wide with

usually half

of it surplus to need. In many countries this is still being burned in

the

field or ploughed back into the soil, but in some developed countries

environmental legislation which restrict field burning has drawn

attention to

its potential as an energy resource Effort to remove crop residues from

soils and to use them for energy purposes

leads to a central question: how much residue should be left and

recycled

into soil to sustain production of biomass ? According to the

experience from

developed countries around 35% of crop residues can be removed from

soil

without adverse effects on future plant production.

Industrial waste that contains biomass may be used to produce energy.

For

example the sludge left after alcohol production (known as vinasse) can

produce

flammable gas. Other useful waste products include, waste from food

processing

and fluff from the cotton and textiles industry.

SHORT ROTATION PLANTS

Biomass

can be also be

produced by so-called short-rotation plantation of trees and other

plants like

grasses (sorghum, sugarcane, switchgrass). All these plants can be used

as

fuels like wood with the main advantage of their short span between

plantation

and harvesting – typically between three and eight years. For some

grasses

harvesting is taking place every six to 12 months. Recently there are

about 100

million hectares of land utilised for tree plantation world-wide. Most

of these

trees are used for forest products markets.

Biomass

can be also be

produced by so-called short-rotation plantation of trees and other

plants like

grasses (sorghum, sugarcane, switchgrass). All these plants can be used

as

fuels like wood with the main advantage of their short span between

plantation

and harvesting – typically between three and eight years. For some

grasses

harvesting is taking place every six to 12 months. Recently there are

about 100

million hectares of land utilised for tree plantation world-wide. Most

of these

trees are used for forest products markets.

Parameters which are important in evaluating species for short

rotation

plants include availability of planting stock, ease of propagation,

survival

ability under adverse conditions and the yield potential measured as

dry matter

production per hectare per year (t/ha/y). Yield is a measure of a

plant’s

ability to utilize the site resources. It is the most important factor

when

considering biomass production due to the need to optimize/maximize

yield from

a given area of land within a given time frame at the least possible

cost. High

yielding species are therefore preferred for biomass energy systems.

Some plant communities have shown superiority in dry matter

production

compared to others grown under similar conditions. Although reported

dry matter

production of different tree species varies over a wide range depending

on soil

types and climate, certain species stand out. For Eucalyptus species,

yields of

up to 65 t/ha/y have been reported, compared to 30 and 43 t/ha/y in

Salix and

Populus species respectively.

Despite the fact that biomass plantation can be of great importance

for most

developed countries experience has shown it is unlikely to be

established on a

large scale in many developing countries, especially in poor rural

areas, so

long as biofuels (particularly wood) can be obtained at zero or near

zero cost.

BIOMASS FUELS IN DEVELOPING

COUNTRIES

Despite its wide use in

developing countries, biomass energy is usually used so inefficiently

that only

a small percentage of its useful energy is obtained. The overall

efficiency in

traditional use is only about 5-15 per cent, and biomass is often less

convenient

to use compared with fossil fuels. It can also be a health hazard in

some

circumstances, for example, cooking stoves can release particulates,

CO, NOx

formaldehyde, and other organic compounds in poorly ventilated homes,

often far

exceeding recommended WHO (World health Organisation) levels.

Furthermore, the

traditional uses of biomass, i.e., burning of wood is often associated

with the

increasing scarcity of hand-gathered wood, nutrient depletion, and the

problems

of deforestation and desertification. Recently almost 1,3 billion

people is

meeting their fuelwood needs by depleting wood reserves.

Share of

biomass on

total energy consumption:

Nepal 95 %

Malawi 94 %

Kenya 75 %

India 50 %

China 33 %

Brazil 25 %

Egypt 20 %

There is an enormous

biomass potential that can be tapped by improving the utilization of

existing

resources and by increasing plant productivity. Bioenergy can be

modernized

through the application of advanced technology to convert raw biomass

into

modern, easy-to-use carriers (such as electricity, liquid or gaseous

fuels, or

processed solid fuels). Therefore, much more useful energy could be

extracted

from biomass than at present. This could bring very significant social

and

economic benefits to both rural and urban areas. The present lack of

access to

convenient sources limits the quality of life of millions of people

throughout

the world, particularly in rural areas of developing countries. Growing

biomass

is a rural, labour-intensive activity, and can, therefore, create jobs

in rural

areas and help stem rural-to-urban migration, whilst, at the same time,

providing convenient carriers to help promote other rural industries.

Fuelwood

The term fuelwood

describe all types of fuels derived from forestry and plantation.

Fuelwood

accounts for about 10 per cent of the total used in the world. It

provides

about 20 % of all used in Asia and Latin America, and about 50 % of

total used

in Africa. However, it is the major source of, in particular for

domestic

purposes, in poor developing countries: in 22 countries, fuelwood

accounted for

25 to 49 %, in 17 countries, 50-74 %, and in 26 countries, 75-100 % of

their

respective national consumption.

More than half of the total wood harvested in the world is used as

fuelwood.

For specific countries, for example in Tanzania, the contribution can

be as

high as 97% . Although fuelwood is the major source of for most rural

and

low-income people in the developing world, the potential supply of

fuelwood is

dwindling rapidly, leading to scarcity of and environmental

degradation. It is

estimated that, for more than a third of the world population, the real

crisis

is the daily scramble to obtain fuelwood to meet domestic use.

Several studies on fuelwood supply in developing countries have

concluded

that fuelwood scarcities are real and will continue to exist, unless

appropriate approaches to resource management are undertaken. The

increase of

fuelwood production through efficient techniques, can, therefore, be

considered

as one of the major pre-requisites for attaining sustainable

development in

developing countries.

Charcoal

The main expansion in the use of charcoal in Europe came with the

industrial

revolution in England in the 17th and 18th centuries. In Sweden,

charcoal

consumption for iron making grew through most of the 19th century, and

was the

basis of the good quality tradition of Swedish steel. Today charcoal is

an

important household fuel and to a lesser extent, industrial fuel in

many

developing countries. It is mainly used in the urban areas where its

ease of

storage, high content (30 MJ/kg as compared with 15 MJ/kg in fuelwood),

lower

levels of smoke emissions, and, resistance to insect attacks make it

more

attractive than fuelwood. In the United Republic of Tanzania, charcoal

accounts

for an estimated 90 per cent of biofuels consumed in urban centres.

![]()

RESIDUES

Agricultural residues

have an enormous potential for production. In favorable circumstances,

biomass

power generation could be significant given the vast quantities of

existing

forestry and agricultural residues - over 2 billion t/yr. world-wide.

This

potential is currently under-utilized in many areas of the world. In

wood-scarce areas, such as Bangladesh, China, the northern plains of

India, and

Pakistan, as much as 90 per cent of household in many villages covers

their

energy needs with agricultural residues. It has been estimated that

about 800

million people world-wide rely on agricultural residues and dung for

cooking,

although reliable figures are difficult to obtain. Contrary to the

general

belief, the use of animal manure as a source is not confined to

developing

countries alone, e.g., in California a commercial plant generates about

17.5 MW

of electricity from cattle manure, and a number of plants are operating

in the

Europe.

There is 54 EJ of biomass energy theoretically available from

recoverable

residues in developing countries and 42 EJ in industrialized regions.

The

amount of potentially recoverable residues includes the three main

sources:

forestry, crops and dung. The calculations assume only 25 per cent of

the

potentially harvestable residues are likely to be used. Sugarcane

residues

(bagasse, and leaves) - are particularly important and offer an

enormous

potential for generation of electricity. Generally, residues are still

used

very inefficiently for electricity production, in many cases

deliberately to

prevent their accumulation, but also because of lack of technical and

financial

capabilities in developing countries.

Depending on the choice of the gas turbine technology and the extent to

which

cane tops and leaves can be used, according to some estimates amount of

electricity that can be produced from cane residues could be up to 44

times the

on-site needs of the sugar factory or alcohol distillery. For each

litre of

alcohol produced a BIG/STIG technology unit could be able to produce

more than

11 kWh of electricity in excess of the distillery’s needs (about 820

kWh/t).

Another estimate of bagasse in condensing-extraction steam turbines

puts the

surplus electricity values at 20-65 kWh per ton of cane, and this

surplus could

be doubled by using barbojo for generation during the off-season. The

cost of

the generated electricity is estimated to be about $US 0,05/kWh.

Revenues from

the sale of electricity co-produced with sugar could be comparable with

sugar

revenues, or alternatively, revenues from the sale of electricity

co-produced

with ethanol could be much greater than the alcohol revenues. In the

latter

instance, electricity would become the primary product of sugarcane,

and

alcohol the by-product.

In India alone, electricity production from sugarcane residues by the

year 2030

could be up to 550 TWh/year (the total electricity production from all

sources

in 2004 was around 530 TWh . Globally, it has been estimated that about

50,000

MW could be supported by currently produced residues. The theoretical

potential

of residues in the 80 sugarcane-producing developing countries could be

up to

2800 TWh/yr. Studies of the sugarcane industry indicate a combined

power

capability in excess of 500 TWh/yr. Assuming that a third of the global

residue

resources could economically and sustainably be recovered by new energy

technology, 10 per cent of the current global electricity demand could

be

generated.

Obviously, to achieving such goals, these are theoretical calculations

with

country- and site specific problems. They do however emphasize the

potential

which many countries have to provide a substantial proportion of their

energy

needs from biomass grown on a sustainable basis.

METHODS

OF

GENERATING ENERGY FROM BIOMASS

Nearly all types of raw

biomass decompose rather quickly, so few are very good long-term energy

stores;

and because of their relatively low energy densities, they are likely

to be

rather expensive to transport over appreciable distances. Recent years

have

therefore seen considerable effort devoted to the search for the best

ways to

use these potentially valuable sources of energy.

In considering the methods for extracting the energy, it is possible

to

order them by the complexity of the processes involved:

![]() Direct

combustion of biomass.

Direct

combustion of biomass.

![]() Thermochemical

processing to upgrade the biofuel. Processes in this category include

pyrolysis, gasification and liquefaction.

Thermochemical

processing to upgrade the biofuel. Processes in this category include

pyrolysis, gasification and liquefaction.

![]() Biological

processing.

Natural processes such as anaerobic digestion and fermentation which

lead to a

useful gaseous or liquid fuel.

Biological

processing.

Natural processes such as anaerobic digestion and fermentation which

lead to a

useful gaseous or liquid fuel.

The immediate ‘product, of some of these processes is heat - normally used at place of production or at not too great a distance, for heating purposes, chemical processing or to generate steam for power production. For other processes the product is a solid, liquid or gaseous fuel: charcoal, liquid fuel like ethanol as a petrol substitute or additive, gas for sale or for power generation using either steam or gas turbines.

COMBUSTION

The technology of direct

combustion as the most obvious way of extracting energy from biomass is

well

understood, straightforward and commercially available. Combustion

systems come

in a wide range of shapes and sizes burning virtually any kind of fuel,

from

chicken manure and straw bales to tree trunks, municipal refuse and

scrap

tyres. Some of the ways in which heat from burning wastes is currently

used

include space and water heating, industrial processing and electricity

generation. One problem with this method is its low efficiency. With an

open

fire most of the heat is wasted and is not used to cook or whatever.

Combustion of wood can be divided into four phases:

![]() Water

inside the

wood boils off. Even wood that has been dried for ages has as much as

15 to 20%

of water in its cell structure.

Water

inside the

wood boils off. Even wood that has been dried for ages has as much as

15 to 20%

of water in its cell structure.

![]() Gas

content is

freed from the wood. It is vital that these gases should burn and not

just

disappear up the chimney.

Gas

content is

freed from the wood. It is vital that these gases should burn and not

just

disappear up the chimney.

![]() The gases

emitted

mix with atmospheric air and burn at a high temperature.

The gases

emitted

mix with atmospheric air and burn at a high temperature.

![]() The rest

of the

wood (mostly carbon) burns. In perfect combustion the entire energy is

utilised

and all that is left is a little pile of ashes.

The rest

of the

wood (mostly carbon) burns. In perfect combustion the entire energy is

utilised

and all that is left is a little pile of ashes.

Three things are needed for effective burning:

![]() high

enough

temperatures;

high

enough

temperatures;

![]() enough

air, and

enough

air, and

![]() enough

time for

full combustion.

enough

time for

full combustion.

If not enough air gets

in, combustion is incomplete and the smoke is black from the unburned

carbon.

It smells terrible, and you get soot deposited in the chimney, with the

risk of

fire. If too much air gets in the temperature drops and the gases

escape

unburned, taking the heat with them. The right amount of air gives the

best

utilisation of fuel. No smell, no smoke, and very little risk of

chimney fires.

Regulation of the air supply depends largely on the chimney and the

draught it

can put up.

Direct combustion is the simplest and most common method of

capturing the

energy contained within biomass. Boiling a pan of water over a wood

fire is a

simple process. Unfortunately, it is also very inefficient, as a little

elementary calculation reveals.

The energy content of a cubic metre dry wood is 10 GJ, which is ten

million

kJ. To raise the temperature of a litre of water by 1 degree Celsius

requires

4,2 kJ of heat energy. Bringing a litre to the boil should therefore

require

rather less than 400 kJ, equivalent to 40 cubic centimetres of wood -

one small

stick, perhaps. In practice, with a simple open fire we might need at

least

fifty times this amount: a conversion efficiency no better than 2%.

Designing a stove or boiler which will make rather better use of

valuable

fuel requires an understanding of the processes involved in the

combustion of a

solid fuel. The first is one which consumes rather than produces

energy: the

evaporation of any water in the fuel. With reasonably dry fuel,

however, this

uses only a few percent of the total energy. In the combustion process

itself

there are always two stages, because any solid fuel contains two

combustible

constituents. The volatile matter is released as a mixture of vapours

or

vaporised tars and oils by the fuel as its temperature rises. The

combustion of

these produces the little spurts of pyrolysis.

Modern combustion facilities (boilers) usually produce heat, steam

(used in

industrial process) or electricity. Direct combustion systems vary

considerably

in their design. The fuel choice makes a difference in the design and

efficiency of the combustion system. Direct combustion technology using

biomass

as the fuel is very similar to that used for coal. Biomass and

coal can

be handled and burned in essentially the same fashion. In fact, biomass

can be

“co-fired” with coal in small percentages in existing coal boilers. The

biomass

which is co-fired are usually low-cost feedstocks, like wood or

agricultural

waste, which also help to reduce the emissions typically associated

with coal.

Coal is simply fossilized biomass heated and compressed over millions

of years.

The process which coal undergoes as it is heated and compressed deep

within the

earth, adds elements like sulphur and mercury to the coal. Burning coal

for

heat or electricity releases these elements, which biomass does not

contain.

PYROLYSIS

Pyrolysis is the

simplest and almost certainly the oldest method of processing one fuel

in order

to produce a better one. A wide range of energy-rich fuels can be

produced by

roasting dry wood or even the straw. The process has been used for

centuries to

produce charcoal. Conventional pyrolysis involves heating the original

material

(which is often pulverised or shredded then fed into a reactor vessel)

in the

near-absence of air, typically at 300 - 500 °C, until the volatile

matter has

been driven off. The residue is then the char - more commonly known as

charcoal

- a fuel which has about twice the energy density of the original and

burns at

a much higher temperature. For many centuries, and in much of the world

still

today, charcoal is produced by pyrolysis of wood. Depending on the

moisture

content and the efficiency of the process, 4-10 tonnes of wood are

required to

produce one tonne of charcoal, and if no attempt is made to collect the

volatile matter, the charcoal is obtained at the cost of perhaps

two-thirds of

the original energy content.

Pyrolysis can also be carried out in the presence of a small

quantity of

oxygen (‘gasification’), water (‘steam gasification’) or hydrogen

(‘hydrogenation’). One of the most useful products is methane, which is

a

suitable fuel for electricity generation using high-efficiency gas

turbines.

With more sophisticated pyrolysis techniques, the volatiles can be

collected, and careful choice of the temperature at which the process

takes

place allows control of their composition. The liquid product has

potential as

fuel oil, but is contaminated with acids and must be treated before

use. Fast

pyrolysis of plant material, such as wood or nutshells, at temperatures

of

800-900 degrees Celsius leaves as little as 10% of the material as

solid char

and converts some 60% into a gas rich in hydrogen and carbon monoxide.

This

makes fast pyrolysis a competitor with conventional gasification

methods (see

bellow), but like the latter, it has yet to be developed as a treatment

for

biomass on a commercial scale.

At present, conventional pyrolysis is considered the more attractive

technology. The relatively low temperatures mean that fewer potential

pollutants are emitted than in full combustion, giving pyrolysis an

environmental advantage in dealing with certain wastes. There have been

some

trials with small-scale pyrolysis plants treating wastes from the

plastics industry

and also used tyres - a disposal problem of increasingly urgent concern.

![]()

GASIFICATION

The basic principles of

gasification have been under study and development since the early

nineteenth

century, and during the Second World War nearly a million biomass

gasifier-powered vehicles were used in Europe. Interest in biomass

gasification

was revived during the “energy crisis” of the 1970s and slumped again

with the

subsequent decline of oil prices in the 1980s. The World Bank (1989)

estimated

that only 1000 - 3000 gasifiers have been installed globally, mostly

small

charcoal gasifiers in South America.

Gasification based on wood as a fuel produces a flammable gas

mixture of

hydrogen, carbon monoxide, methane and other non flammable by products.

This is

done by partially burning and partially heating the biomass (using the

heat

from the limited burning) in the presence of charcoal (a natural

by-product of

burning biomass). The gas can be used instead of petrol and reduces the

power

output of the car by 40%. It is also possible that in the future this

fuel

could be a major source of energy for power stations.

SYNTHETIC FUELS

A gasifier which uses

oxygen rather than air can produce a gas consisting mainly of H2, CO

and CO2,

and the interesting potential of this lies in the fact that removal of

the CO2

leaves the mixture called synthesis gas, from which almost any

hydrocarbon

compound may be synthesised. Reacting the H2 and CO is one way to

produce pure

methane. Another possible product is methanol (CH3OH), a liquid

hydrocarbon

with an energy density of 23 GJ per tonne. Producing methanol in this

way involves

a series of sophisticated chemical processes with high temperatures and

pressures and expensive plant, and one might wonder why it is of

interest. The

answer lies in the product: methanol is that valuable commodity, a

liquid fuel

which is a direct substitute for gasoline. At present the production of

methanol using synthesis gas from biomass is not a commercial

proposition, but

the technology already exists, having been developed for use with coal

as

feedstock - as a precaution by coal-rich countries at times when their

oil

supplies were threatened.

FERMENTATION

Fermentation of sugar solution is the way how ethanol (ethyl alcohol) can be produced. Ethanol is a very high liquid energy fuel which can be used as the substitute for gasoline in cars. This fuel is used successfully mainly in Brazil. Suitable feedstocks include crushed sugar beet or fruit. Sugars can also be manufactured from vegetable starches and cellulose by pulping and cooking, or from cellulose by milling and treatment with hot acid. After about 30 hours of fermentation, the brew contains 6-10 per cent alcohol, which can be removed by distillation as a fuel. Fermentation is an anaerobic biological process in which sugars are converted to alcohol by the action of micro-organisms, usually yeast. The resulting alcohol is ethanol (C2H3OH) rather than methanol (CH3OH), but it too can be used in internal combustion engines, either directly in suitably modified engines or as a gasoline extender in gasohol: gasoline (petrol) containing up to 20% ethanol.

The value of any particular type of

biomass as feedstock for fermentation

depends on the ease with which it can be converted to sugars. The best

known

source of ethanol is sugar-cane - or the molasses remaining after the

cane

juice has been extracted. Other plants whose main carbohydrate is

starch

(potatoes, corn and other grains) require processing to convert the

starch to

sugar. This is commonly carried out, as in the production of some

alcoholic

drinks, by enzymes in malts. Even wood can act as feedstock, but its

carbohydrate, cellulose, is resistant to breakdown into sugars by acid

or

enzymes (even in finely divided forms such as sawdust), adding further

complication to the process. The liquid resulting from fermentation

contains only about 10% ethanol, which

must be distilled off before it can be used as fuel. The energy content

of the

final product is about 30 GJ/t, or 24 GJ/m3. The complete process

requires a

considerable amount of heat, which is usually supplied by crop residues

(e.g.

sugar cane bagasse or maize stalks and cobs). The energy loss in

fermentation

is substantial, but this may be compensated for by the convenience and

transportability of the liquid fuel, and by the comparatively low cost

and

familiarity of the technology.

ANAEROBIC DIGESTION

Nature has a provision

of destroying and disposing of wastes and dead plants and animals. Tiny

micro-organisms called bacteria carry out this decay or decomposition.

The

farmyard manure and compost is also obtained through decomposition of

organic

matter. When a heap of vegetable or animal matter and weeds etc. die or

decompose at the bottom of back water or shallow lagoons then the

bubbles can

be noticed rising to the surface of water. Some times these bubbles

burn with

flame at dusk. This phenomenon was noticed for ages, which puzzled man

for a

long time. It was only during the last 200 years or so when scientists

unlocked

this secret, as the decomposition process that takes place under the

absence of

air (oxygen). This gas, production of which was first noticed in marshy

places,

was and is still called as ‘Marsh Gas’. It is now well known that this

gas

(Marsh Gas) is a mixture of Methane (CH4) and Carbon dioxide (CO2) and

is

commonly called as the ‘Biogas’. As per records biogas was first

discovered by

Alessandro Volta in 1776 and Humphery Davy was the first to pronounce

the

presence of combustible gas Methane in the Farmyard Manure in as early

as 1800.

The technology of scientifically harnessing this gas from any

biodegradable

material (organic matter) under artificially created conditions is

known as

biogas technology.

Anaerobic digestion,

like pyrolysis, occurs in the absence of air; but in this case the

decomposition is caused by bacterial action rather than high

temperatures. It

is a process which takes place in almost any biological material, but

is

favoured by warm, wet and of course airless conditions.

BIOGAS

Biogas

is a valuable fuel

which is in many countries produced in purpose built digesters filled

with the

feedstock like manure or sewage. Digesters range in size from one cubic

meter

for a small ‘household’ unit to more than thousand cubic meters used in

large

commercial installation or farm plants. The input may be continuous or

in

batches, and digestion is allowed to continue for a period of from ten

days to

a few weeks. The bacterial action itself generates heat, but in cold

climates

additional heat is normally required to maintain the ideal process

temperature

of at least 35 degrees Celsius, and this must be provided from the

biogas. In

extreme cases all the gas may be used for this purpose, but although

the net

energy output is then zero, the plant may still pay for itself through

the

saving in fossil fuel which would have been needed to process the

wastes. A

well-run digester can produce 200-400 m3 of biogas with a methane

content of

50% to 75% for each dry tonne of input.

|

|

|

|

|

|

|

|

|

|

LANDFILL GAS

A large proportion of

ordinary domestic refuse - municipal solid wastes - is biological

material and

its disposal in landfills creates suitable conditions for anaerobic

digestion. Landfill

sites that produce methane has been known for decades, and recognition

of the

potential hazard led to the fitting of systems for burning it off;

however, it

was only in the 1970s that serious attention was paid to the idea of

using this

‘undesirable’ product.

The waste matter is more miscellaneous in a landfill than in a biogas

digester,

and the conditions neither as warm nor as wet, so the process is much

slower,

taking place over years rather than weeks. The end product, known as

landfill

gas, is again a mixture consisting mainly of CH4 and CO2. In theory,

the

lifetime yield of a good site should lie in the range 150-300 m3 of gas

per

tonne of wastes, with between 50% and 60% by volume of methane. This

suggests a

total energy of 5-6 GJ per tonne of refuse, but in practice yields are

much

less.

In developing a site, each area is covered with a layer of impervious

clay or

similar material after it is filled, producing an environment which

encourages

anaerobic digestion. The gas is collected by an array of interconnected

perforated pipes buried at depths up to 20 metres in the refuse. In new

sites

this pipe system is constructed before the wastes start to arrive, and

in a

large well-established landfill there can be several miles of pipes,

with as

much as 1000 m3 an hour of gas being pumped out.

Increasingly, the gas from landfill sites is used for power generation.

At

present most plants are based on large internal combustion engines,

such as

standard marine engines. Driving 500 kW generators, these are well

matched to

typical gas supply rates of the order of 10 GJ an hour.

![]()

Heating

buildings with biomass

District heating system means the central biomass plant which

provides heat

to several public, commercial, and residential buildings located around

in the

area near the heating plant. These heating systems offer a many

advantages over

the use of individual heating boilers in houses. Efficiency and the

level of

automation are the most important ones. Higher efficiency in central

heating

plants leads to lower fuel consumption, labour requirements and also

emissions.

On the other hand district heating systems may have some limitation in

order to

accomodate new consumers when theete is not sufficient capacity (output

power,

piping etc).

WOOD

BOILERS

Most common process of

biomass combustion is burning of wood. In developed countries replacing

oil or

coal-fired central heating boiler with a wood burning one can save

between 20

and 60% on heating bills, because wood costs less than oil or coal. At

the same

time wood burning units are eco-friendly. They only emit the same

amount of the

greenhouse gas CO2 as the tree absorbed when it was growing. So burning

wood

does not contribute to global warming. Since wood contains less sulphur

than

oil does, less sulphate is discharged into the atmosphere. This means

less acid

rain and less acid in the environment.

SMALL BOILERS

Small wood burning

boilers are frequently used for heating houses. There are approx.

70,000 small

boilers burning firewood, wood chips, or wood pellets in Denmark alone.

Such a

boiler gives off its heat to radiators in exactly the same way as e.g.

an

oil-fired one. In this it differs from a wood burning stove, which only

gives

off its heat to the room it is in. In other words a wood burning boiler

can

heat whole house and provide hot water. For a single family home, a

hand-fired

wood burning boiler is usually the best and most economical investment.

In

larger places such as farms the saving from burning wood is often so

great that

it pays to install an automatic stoker unit burning wood pellets.

Many of small boilers are manually fired with storage tank for wood.

Distinctions should be made between manually fired boilers for fuelwood

and

automatically fired boilers for wood chips and wood pellets. Manually

fired

boilers are installed with storage tank for hot water so as to

accumulate the

heat energy from fuel. Automatic boilers are equipped with a silo

containing

wood pellets or wood chips. A screw feeder feeds the fuel

simultaneously with

the output demand of the dwelling.

Great advances have been made over the recent 10 years for both boiler

types in

respect of higher efficiency and reduced emission from the chimney

(dust and

carbon monoxide). Improvements have been achieved particularly in

respect of

the design of combustion chamber, combustion air supply, and the

automatics

controlling the process of combustion. In the field of manually fired

boilers,

an increase in the efficiency has been achieved from below 50% to

75-90%. For

the automatically fired boilers,

an increase in

the efficiency from60% to 85-92% has been achieved.

MANUALLY

FIRED BOILERS

The principal rule is

that manually fired boilers for fuelwood only have an acceptable

combustion at

the boiler rated output (at full load). At individual plants with

oxygen

control, the load can, however, be reduced to approx. 50% of the

nominal output

without thereby influencing neither the efficiency nor emissions. By

oxygen

control, a lambda probe measures the oxygen content in the flue gas,

and the

automatic boiler control varies the combustion air inlet.

The same system is used in cars. In order for the boiler not to need

feeding at

intervals of 2-4 hours a day, during the coldest periods of the year,

the

fuelwood boiler nominal output is selected so as to be up to 2-3 times

the output

demand of the dwelling. Boilers designed for fuelwood should always be

equipped

with storage tank for hot water. This ensures both the greatest comfort

for the

user and the least financial and environmental strain. In case of no

storage

tank, an increased corrosion of the boiler is often seen due to

variations in

water and flue gas temperatures.

AUTOMATICALLY FIRED BOILERS

Despite an often simple

construction, most of the automatically fired boilers can achieve an

efficiency

of 80-90% and a CO emission of approx. 100 ppm (100 ppm = 0.01 volume

%). For

some boilers, the figures are 92% and 20 ppm, respectively. An

important

condition for achieving these good results is that the boiler

efficiency during

day-to-day operation is close to full load. For automatic boilers, it

is of

great importance that the boiler nominal output (at full load) does not

exceed

the max. output demand in winter periods. In the transition periods

(3-5

months) spring and autumn, the output demand of the dwelling will

typically be

approx. 20-40% of the boiler nominal output, which means a deteriorated

operating result. During the summer period, the output demand of the

dwelling

will often be in the range of 1-3 kW, since only the hot water supply

will be

maintained. This equals 5 -10% of the boiler nominal output. This

operating

method reduces the efficiency - typically 20-30% lower than that of the

nominal

output - and an increased negative effect on the environment. The

alternative

to the deteriorated summer operating is to combine the installation

with a

storage tank and solar collectors.

MANUALLY-FIRED BOILERS

BURN-THROUGH

|

Nearly all old-fashioned cast iron stoves act on the burn-through principle: air comes in from below and passes upwards through the fuel. In burn-through boilers the wood burns very quickly. The gases do not burn very well, since the boiler temperature is low. Most of the gas goes up the chimney, and the energy with it. The flue gases have a very short space in which to give off their heat to the boiler in the convection section. By and large, burn-through furnaces are unsuitable for wood. The useful effect of a burn-through boiler is typically under 50%. |

UNDERBURN BOILERS

|

Underburn boiler is very different from a burn-through one. The air is not drawn through all the fuel at once, but only through part of it. Only the bottom layer of wood burns; the rest dries out and gives off its gases very slowly. Adding extra air (so-called “secondary air”) direct to the flames burns the gases more effectively. In modern underburning boilers the combustion chamber is ceramic lined, which insulates well and keeps the heat in. This gives a high temperature of combustion, burning the gases most effectively. An underburning boiler typically has a useful effect of 65-75%. |

|

In reverse combustion too, air is only added to part of the fuel. As in underburning, the gases leave the fuel slowly and are burnt efficiently. Secondary air is also led into an earthenware-lined chamber, giving a high temperature of combustion. The flue gas has to pass through the entire boiler, giving it plenty of time to give up its heat. The useful effect is typically of the order of 75-85%. Some reverse combustion boilers have a blower instead of natural draught. Such boilers often have slightly better combustion, with less soot and pollution than ones with natural draught, but their useful effect is not significantly better. |

THE EFFICIENCY OF THE BOILER

How good a boiler is

partially depends on the proportion of the energy in the fuel that it

transfers

to the central heating system. This proportion is called the

“efficiency”. The

efficiency of a boiler is defined as the relationship between the

energy in the

hot water and that in the wood: the higher the efficiency, the more of

the

energy in the fuel is transferred to the water in the boiler. Good

boilers have

a efficiency of the order of 80-90%.

The a wood consumption in reverse burning boiler is typically between 4

kg/hour

for 18 kW boiler to 18 kg/hr for 80 kW boiler. In Central European

condition an

average single family house (150 m2) need cca 12 m3 of wood for the

whole

heating season. Typical boilers can burn wood logs up to 80 cm

long. For

more technical data for Central European conditions see the table

bellow.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BURNING WOOD COMBINED WITH

SOLAR

HEATING

If the building is

equipped with the wood burning unit, it is recommended also to consider

putting

in solar heating. The wood burning boiler and the solar panels can

frequently

use the same storage tank, reducing the cost of the system as a whole.

At the

same time it makes it unnecessary to have a fire going in summer just

to get

hot water. And it is cheaper to use solar energy than to burn the wood!

FUEL CHOICE

Whatever

fuel is chosen

for use, it must be dry. Newly felled timber has a water content of

about 50%,

which makes it uneconomical to burn. This is because a proportion of

the energy

in the wood goes to evaporating the water off, giving less energy for

heat. So

wood has to be dried before it can be burnt. The best thing to do is to

leave

the wood to dry for at least a year, and preferably two. It is easiest

to stack

it in an outdoor woodshed so that the rain cannot get at it.

Whatever

fuel is chosen

for use, it must be dry. Newly felled timber has a water content of

about 50%,

which makes it uneconomical to burn. This is because a proportion of

the energy

in the wood goes to evaporating the water off, giving less energy for

heat. So

wood has to be dried before it can be burnt. The best thing to do is to

leave

the wood to dry for at least a year, and preferably two. It is easiest

to stack

it in an outdoor woodshed so that the rain cannot get at it.

Never burn wood that has been painted or glued, since toxic gases

are formed

on combustion. Nor should one burn refuse such as waxed paper milk

cartons and

that sort of thing. You can also burn wood briquettes. They are made of

compressed sawdust and wood shavings, about 10 or 20 cm long and 5 cm

in

diameter. Because they are compressed and have a low water content they

have a

higher energy density than ordinary wood, so they need less storage

space.

CHIMNEY

Chimney is responsible

for the draught going through the boiler. The difference in the density

of the

air between the top of the chimney and the outlet on the boiler is what

creates

the draught. So the height of the chimney, the insulation, and thus the

temperature of the smoke all contribute to the draught. Bends and

horizontal

bits of piping reduce the draught. They create resistance, which the

hot air

has to overcome. So the idea is to have as few horizontal flues and

bends as

possible. Some boilers have a built-in blower, ensuring a proper

draught at all

times.

BOILER MAINTENANCE

A boiler must be

installed and maintained properly. This increases its life and the

safety. Most

countries have regulations about siting: in some places boilers have to

be put

in a separate room. The chimney will need sweeping at least once a

year. This

reduces the risk of fire. Too much soot may mean that there is not

enough air flowing

through.

WOOD PELLETS AND WOOD CHIPS IN AUTOMATICALLY-FIRED BOILERS

|

The automatic boiler is connected to the central heating system in exactly the same way as e.g. an oil-fired one. The heat of combustion is transferred to water, which is heated up and carried round the house to the radiators. The automatic boiler thus supplies heat to all the radiators in the house, unlike a wood burning stove, which only heats the room it is in. Pellets and wood-chips are of a size and shape that make them ideal for automatic boilers, since they can be fed in directly from a bunker. This makes it much easier to stoke, since the bunker only needs filling up once or twice a week. In hand-fired units like wood burning boilers, one has to stoke up several times a day - though they are usually cheaper to buy than automatic ones. |

WOOD PELLETS

|

Wood pellets are a comparatively new and attractive form of fuel. When people burn wood pellets, they are utilising an energy resource that would otherwise have gone to waste or been dumped in a landfill. Pellets are usually made out of waste (sawdust and wood shavings), and are used in large quantities by district heating systems. The pellets are made in presses, and come out 1-3 cm long and about 1 cm wide. They are clean, pleasant smelling and smooth to touch. Wood pellets have a low moisture content (under 10% by weight), giving them a higher combustion value than other wood fuels. The fact that they are pressed means they take up less space, so they have a higher volume energy (more energy per cubic meter). The burning process is highly combustible and produces little residue. Some countries have exempted pellet appliances from the smoke emission testing requirements. |

There are different

kinds of pellets. Some manufacturers use a bonding agent to extend the

life of

the pellets; others make them without it. The bonder used often

contains

sulphur, which goes up the chimney on burning. Sulphate pollution

contributes

to acid rain and chimney corrosion, so it is best to buy pellets

without a

bonding agent.

Wood pellets characteristics:

Diameter : 5 - 8 mm

Length : max. 30 mm

Density : min. 650 kg/m3

Moisture content : max. 8% of weight

Energy value : 4,5 - 5,2 kWh/kg

2 kg pellets = 1 litre of heating oil

There are many

advantages in using pellets as the fuel of choice. No trees are cut to

make the

pellets - they are only made from leftover wood residue. Burning pellet

fuel

actually helps reduce waste created by lumber production or furniture

manufacturing. There are no additives put into the pellets to make them

burn

longer or more efficiently. Pellet fuel does not smoke or give off any

harmful

fumes. Using this fuel reduces the need for fossil fuels which are

known to be

harmful for the environment.

The cost of pellet fuel may depend on the geographic region where it is

sold,

and the current season. Whether users live in a condominium in the city

or a

home in the country, pellet fuel is among the safest, healthiest way to

heat.

This technology is also valuable for non-residential buildings such as

hotels,

resorts, restaurants, retail stores, offices, hospitals, and schools.

Pellets

are recently used in 20.000 buildings in Germany (3% of all boilers)

and in over

500 000 homes in North America.

Annual pellet

consumption in selected countries in 2006.

WOOD CHIPS

|

Wood-chips

are made of

waste wood from the forests. Trees have to be thinned to make room for

commercial timber (beams, flooring, furniture). Wood-chips are thus a

waste

product of normal forestry operations. Wood is cut up in

mechanical

chippers. The size and shape of the chips depends on the machine, but

they are

typically about a centimeter thick and 2 to 5 cm long. The water

content of

newly felled chips is usually about 50% by weight, but this drops

considerably

on drying. Careful processing and drying enable optimal storage and

trouble-free operation of heating systems

with negligible

production of ash and low emissions. |

|

|

|

|

|

Wood chips

are usually locally

produced and environmentally friendly energy source which are not

subject to

crises. Their utilisation also secure domestic jobs. It is mainly local

farmers

who are involved with the production and sales of wood chips. And for their production not one single tree

more has to be cut down. Every year, more wood grows in forrests than

is used thus

all kinds of waste wood material is suitable for use as wood chips

including

wood damaged by storms. In many countries like in Denmark wood-chips

currently

produced are burnt in wood-chip fired district heating stations. For

the

utilisation in single family houses they are usually delivered by road,

so

there must be facilities for storing at least 20 m3 of chips under

cover if

they are to be used in an automatic burner.

Wood logs, chips and pellets

In the table bellow you can find a comparison of different wood

burning

systems for single family house 150 m2 (12 kW heat load). Data are from

Austria.

|

Fuel |

Fuel

consumption in heating season |

Operation |

|

Logs |

12 m3 |

Fuel input 1-2 times a day |

|

Wood chips |

28 m3 |

Fuel input 1-2 times a year |

|

Wood Pellets |

7,5 m3 |

Automatic |

BOILER TYPES FOR WOOD PELLETS AND

WOOD CHIPS

Automatic furnaces come in three types :

![]() Compact

units in

which the boiler and bunker are in one.

Compact

units in

which the boiler and bunker are in one.

![]() Stoker-fired

units, with separate boiler and bunker.

Stoker-fired

units, with separate boiler and bunker.

![]() Boilers

with

built-in pre-furnace.

Boilers

with

built-in pre-furnace.

In compact units the

fuel is fed into the fire from the bunker by an automatic feeder. The

rate at

which fuel is fed in is determined by a thermostat, which puts less in

when the

water is hot and more in when it is cold. Compact units are excellent

for wood

pellets, but not for wood-chips. This is due to the lower volume energy

of

chips, so that stoking has to be more frequent. In addition, the water

content

of wood-chips is often so high that compact units do not combust them