|

|

Solar energy runs the engines of the earth. It heats its atmosphere and its lands, generates its winds, drives the water cycle, warms its oceans, grows its plants, feeds its animals, and even (over the long haul) produces its fossil fuels. This energy can be converted into heat and cold, driving force and electricity. |

SOLAR RADIATION

|

|

Solar radiation is electromagnetic radiation in the

0.28...3.0 µm wavelength range. The solar spectrum includes a small share of

ultraviolet radiation (0.28...0.38 µm) which is invisible to our eyes and

comprises about 2% of the solar spectrum, the visible light which range from

0.38 to 0.78 µm and accounts for around 49% of the spectrum and finally of

infrared radiation with long wavelength (0.78...3.0 µm), which makes up most

of the remaining 49% of the solar spectrum. |

HOW MUCH SOLAR ENERGY

STRIKES THE EARTH?

The sun generates an enormous amount of energy - approximately 1.1 x 10 E20

kilowatt-hours every second. (A kilowatt-hour is the amount of energy needed to

power a 100 watt light bulb for ten hours.) The earth's outer atmosphere

intercepts about one two-billionth of the energy generated by the sun, or about

1500 quadrillion (1.5 x 10 E18 ) kilowatt-hours per year. Because of

reflection, scattering, and absorption by gases and aerosols in the atmosphere,

however, only 47% of this, or approximately 700 quadrillion (7 x 10 E17 )

kilowatt-hours, reaches the surface of the earth.

|

|

In the earth's atmosphere, solar radiation is received directly (direct radiation) and by diffusion in air, dust, water, etc., contained in the atmosphere (diffuse radiation). The sum of the two is referred to as global radiation. |

The amount of incident energy per unit area and day

depends on a number of factors, e.g.:

![]() latitude

latitude

![]() local climate

local climate

![]() season of the year

season of the year

![]() inclination of the collecting surface in the direction of the

sun.

inclination of the collecting surface in the direction of the

sun.

TIME AND SITE

The solar energy varies because of the relative motion of the sun. This

variations depend on the time of day and the season. In general, more

solar radiation is present during midday than during either the early morning

or late afternoon. At midday, the sun is positioned high in the sky and the path

of the sun's rays through the earth's atmosphere is shortened. Consequently,

less solar radiation is scattered or absorbed, and more solar radiation reaches

the earth's surface.

The amounts of solar energy arriving at the earth's surface vary over the

year, from an average of less than 0,8 kWh/m2 per day during winter in the

North of Europe to more than 4 kWh/m2 per day during summer in this region. The

difference is decreasing for the regions closer to the equator.

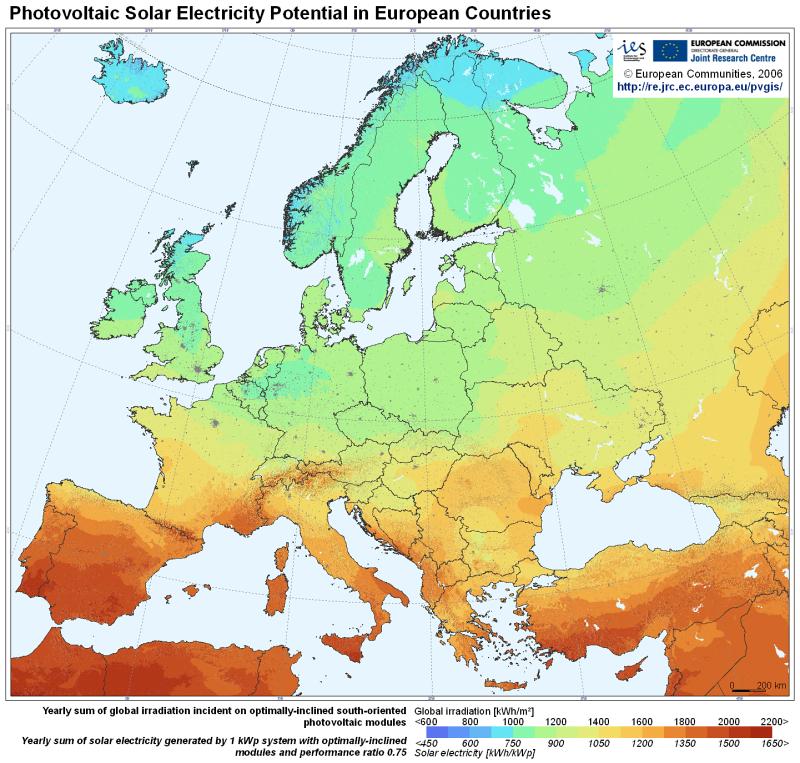

The availability of solar energy varies with geographical location of site

and is the highest in regions closest to the equator. Thus the average annual

global radiation impinging on a horizontal surface which amounts to approx.

1000 kWh/m2 in Central Europe, Central Asia, and Canada reach approx. 1700

kWh/m2 in the Mediterranian and to approx. 2200 kWh/m2 in most equatorial

regions in African, Oriental, and Australian desert areas. In general, seasonal

and geographical differences in irradiation are considerable (see the table

bellow) and must be taken into account for all solar energy applications.

Variations of solar irradiation

(tilt angle South 30Deg.) in Europe and Caribbean region in kWh/m2.day.

|

|

Southern Europe |

Central Europe |

North Europe |

Caribbean |

|

January |

2,6 |

1,7 |

0,8 |

5,1 |

|

February |

3,9 |

3,2 |

1,5 |

5,6 |

|

March |

4,6 |

3,6 |

2,6 |

6,0 |

|

April |

5,9 |

4,7 |

3,4 |

6,2 |

|

May |

6,3 |

5,3 |

4,2 |

6,1 |

|

June |

6,9 |

5,9 |

5,0 |

5,9 |

|

July |

7,5 |

6,0 |

4,4 |

6,0 |

|

August |

6,6 |

5,3 |

4,0 |

6,1 |

|

September |

5,5 |

4,4 |

3,3 |

5,7 |

|

October |

4,5 |

3,3 |

2,1 |

5,3 |

|

November |

3,0 |

2,1 |

1,2 |

5,1 |

|

December |

2,7 |

1,7 |

0,8 |

4,8 |

|

YEAR |

5,0 |

3,9 |

2,8 |

5,7 |

|

For more World Solar Irradiation Data go to : CD directory named SOFT and double click on sunny.exe |

CLOUDS

The amount of solar radiation reaching the earth's surface varies greatly

because of changing atmospheric conditions and the changing position of the

sun, both during the day and throughout the year. Clouds are the predominant

atmospheric condition that determines the amount of solar radiation that

reaches the earth. Consequently, regions of the nation with cloudy climates

receive less solar radiation than the cloud-free desert climates. For any given

location, the solar radiation reaching the earth's surface decreases with

increasing cloud cover. Local geographical features, such as mountains, oceans,

and large lakes, influence the formation of clouds; therefore, the amount of

solar radiation received for these areas may be different from that received by

adjacent land areas. For example, mountains may receive less solar radiation

than adjacent foothills and plains located a short distance away. Winds blowing

against mountains force some of the air to rise, and clouds form from the

moisture in the air as it cools. Coastlines may also receive a different amount

of solar radiation than areas further inland.

The solar energy which is available during the day varies and depends

strongly on the local sky conditions. At noon in clear sky conditions, the

global solar irradiation can in e.g. Central Europe reach 1000 W/m2 on a

horizontal surface (under very favourable conditions, even higher levels can

occur) whilst in very cloudy weather, it may fall to less than 100 W/m2 even at

midday.

POLLUTION

Both man-made and naturally occurring events can limit the amount of solar

radiation at the earth's surface. Urban air pollution, smoke from forest fires,

and airborne ash resulting from volcanic activity reduce the solar resource by

increasing the scattering and absorption of solar radiation. This has a larger

impact on radiation coming in a direct line from the sun (direct radiation)

than on the total (global) solar radiation. On a day with severely polluted air

(smog alert), the direct solar radiation can be reduced by 40%, whereas the

global solar radiation is reduced by 15% to 25%. A large volcanic eruption may

decrease, over a large portion of the earth, the direct solar radiation by 20%

and the global solar radiation by nearly 10% for 6 months to 2 years. As the

volcanic ash falls out of the atmosphere, the effect is diminished, but

complete removal of the ash may take several years.

POTENTIALS

Solar radiation provides us at zero cost with 10,000 times more energy than is

actually used worldwide. All people of the world buy, trade, and sell a little

less than 85 trillion (8.5 x 1013 ) kilowatt-hours of energy per year. But that's

just the commercial market. Because we have no way to keep track of it, we are

not sure how much non-commercial energy people consume: how much wood and

manure people may gather and burn, for example; or how much water individuals,

small groups, or businesses may use to provide mechanical or electrical energy.

Some think that such non-commercial energy may constitute as much as a fifth of

all energy consumed. But even if this were the case, the total energy consumed

by the people of the world would still be only about one seven-thousandth of

the solar energy striking the earth's surface per year.

In some developed countries like in the United States people consume roughly 25 trillion (2.5 x 10E13 ) kilowatt-hours per year. This translates to more than 260 kilowatt-hours per person per day - this is the equivalent of running more than one hundred 100 watt bulbs all day, every day. U.S. citizen consumes 33 times as much energy as the average person from India, 13 times as much as the average Chinese, two and a half times as much as the average Japanese, and twice as much as the average Sweden.

Even in such heavy energy consuming countries like USA solar energy

falling on the land mass can many times surplus the energy consumed

there. If only 1% of land would be set aside and covered by solar systems (such

as solar cells or solar thermal troughs) that were only 10% efficient, the

sunshine falling on these systems could supply this nation with all the energy

it needed. The same is true for all other developed countries. In a certain

sense, it is impractical - besides being extremely expensive, it is not

possible to cover such large areas with solar systems. The damage to

ecosystems might be dramatic. But the principle remains. It is possible to

cover the same total area in a dispersed manner - on buildings, on houses,

along roadsides, on dedicated plots of land, etc. In another sense, it is

practical. In many countries already more than 1% of land is dedicated to the

mining, drilling, converting, generating, and transporting of energy. And the

great majority of this energy is not renewable on a human scale and is far more

harmful to the environment than solar systems would prove to be.

![]()

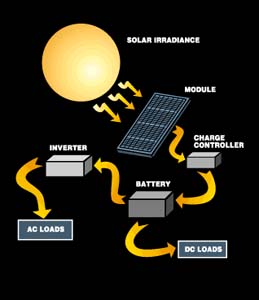

SOLAR ENERGY UTILISATION

In most places of the world much more solar energy hits a home's roof and

walls as is used by its occupants over a year's time. Harnessing this sun's

light and heat is a clean, simple, and natural way to provide all forms of

energy we need. It can be absorbed in solar collectors to provide hot water or

space heating in households and commercial buildings. It can be concentrated by

parabolic mirrors to provide heat at up to several thousands degrees Celsius.

This heat can be used either for heating purposes or to generate electricity.

There exist also another way to produce power from the sun - through

photovoltaics. Photovoltaic cells are devices which convert solar radiation

directly into electricity.

Solar radiation can be converted into useful energy using active systems and passive solar design. Active systems are generally those that are very visible like solar collectors or photovoltaic cells. Passive systems are defined as those where the heat moves by natural means due to house design which entails the arrangement of basic building materials to maximize the sun's energy.

Solar energy can be converted to useful energy also indirectly, through other energy forms like biomass, wind or hydro power. Solar energy drives the earth´s weather. A large fraction of the incident radiation is absorbed by the oceans and the seas, which are warmed than evaporate and give the power to the rains which feed hydro power plants. Winds which are harnessed by wind turbines are getting its power due to uneven heating of the air. Another category of solar-derived renewable energy sources is biomass. Green plants absorb sunlight and convert it through photosynthesis into organic matter which can be used to produce heat and electricity as well. Thus wind, hydro power and biomass are all indirect forms of solar energy.

Passive solar design, or climate responsive buildings use

existing technologies and materials to heat, cool and light buildings. They

integrate traditional building elements like insulation, south-facing glass,

and massive floors with the climate to achieve sustainable results. These

living spaces can be built for no extra cost while increasing affordability

through lower energy payments. In many countries they also keep investment in

the local building industry rather than transferring them to short term energy

imports. Passive solar buildings are better for the environment while

contributing to an energy independent, sustainable energy future.

Passive solar system uses the building structure as a collector, storage and

transfer mechanical equipment. This definition fits most of the more simple

systems where heat is stored in the basic structure: walls, ceiling or floor.

There are also systems that have heat storage as a permanent element within the

building structure, such as bins of rocks, or water-filled drums or bottles.

These are also classified as passive solar energy systems. Passive solar homes

are ideal places in which to live. They provide beautiful connections to the

outdoors, give plenty of natural light, and save energy throughout the year.

HISTORY

Building design has historically borrowed its inspiration from the local

environment and available building materials. More recently, humankind has

designed itself out of nature, taking a path of dominance and control which led

to one style of building for nearly any situation. In 100 A.D., Pliny the

Younger, a historical writer, built a summer home in Northern Italy featuring

thin sheets of mica windows on one room. The room got hotter than the others

and saved on short supplies of wood. The famous Roman bath houses in the first to

fourth centuries A.D. had large south facing windows to let in the sun's

warmth. By the sixth century, sunrooms on houses and public buildings were so

common that the Justinian Code initiated “sun rights” to ensure individual

access to the sun. Conservatories were very popular in the 1800's creating

spaces for guests to walk through warm greenhouses with lush foliage.

Passive solar buildings in the United States were in such demand by 1947, as a result of scarce energy during the prolonged World War 2, that Libbey-Owens-Ford Glass Company published a book entitled Your Solar House, which profiled forty-nine of the nations greatest solar architects.

In the mid-1950's, architect Frank Bridgers designed the world's first

commercial office building using solar water heating and passive design. This

solar system has been continuously operating since that time and the Bridgers-Paxton

Building is now in the National Historic Register as the world's first solar

heated office building.

Low oil prices following World War 2 helped keep attention away from solar

designs and efficiency. Beginning in the mid-1990's, market pressures are

driving a movement to redesign our building systems to more in line with

nature.

![]()

Passive Solar Space Heating

|

|

There are few basic architectural modes for the

utilisation of passive solar utilisation in architecture. But these modes, as

presented below, can be developed into many different scheme, and enrich the

design. |

Site

Landscaping and Trees

According to the U.S. Department of Energy report, “Landscaping for Energy

Efficiency” (DOE/GO-10095-046), careful landscaping can save up to 25% of a

household's energy consumption for heating and cooling. Trees are very

effective means of shading in the summer months as well as providing breaks for

the cool winter winds. In addition to contributing shade, landscape features

combined with a lawn or other ground cover can reduce air temperatures as much

as 5 degrees Celsius in the surrounding area when water evaporates from

vegetation and cools the surrounding air. Trees are wonderful for natural

shading and cooling, but they must be located appropriately so as to provide

shade in summer and not block the winter sun. Even deciduous trees that lose

their leaves during cold weather block some winter sunlight - a few bare trees

can block over 50 percent of the available solar energy.

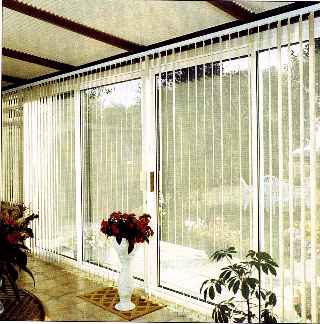

Windows

|

|

All effective passive systems depend on windows. Glass or other translucent materials allow short-wave, solar radiation to enter a building and prohibit the long-wave, heat radiation, from escaping. Windows control the energy flow in two principle ways: they admit solar energy in winter, so warming the house above the otherwise cool to cold internal conditions; and by excluding sun from the windows (by orientation and shading) there exist the opportunity to use ventilation to cool the otherwise warm hot house in summer. If use is to be made of the sun's heat, then it has to reach buildings when it is useful. Generally, the sun should be able to reach the collection area between 9 a.m. and 3 p.m. in winter with as little obstruction and interference as possible.Trees on the site or the neighbours' site might shade the vital areas of the building. This need to be checked and the building located to minimise any such interference. It is possible to plan a house to have its main outlook in any direction and still be an efficient low energy building. The building envelope, i.e. the walls, floor and roof are the important elements in design, rather than the location of internal spaces. If a window needs to face west it requires correct shading and its size restricted. |

Glass permits sun radiation of wavelengths 0.4 to 2.5 microns to pass through it. As this radiant energy collides with opaque objects on the other side of the glass, it's wavelength increases to 11 microns. Glass acts as an opaque barrier to light of this wavelength thereby trapping the sun's energy. The amount of light penetrating a glass is dependent on the angle of incidence. The optimum angle of incidence is 90o. When sunlight strikes the glass at 30o or less, the most radiation is reflected.

![]()

Understanding the Solar

Spectrum and Heat Transfer

To make good choices on glazing, it is needed to understand a bit about

light and heat. The sunlight that strikes the Earth is comprised of a variety

of wavelengths and different glazing will selectively transmit, absorb, and

reflect the various components of the solar spectrum. Likewise, reducing glare

(via reflection or tinting) is helpful in the workplace by allowing the

transmission of visible, or natural, light it is possible to save energy for

artificial light. But perhaps the greatest effect on human comfort levels is

determined by infrared heat transfer. By specifying the right type of glass, it

is possible to trap the infrared heat for warmth, or reflect the infrared heat

to prevent warming.

There are three ways that heat moves through a glazing material. The

first is conduction. Conductive heat is transferred through the glazing by

direct contact. Heat can be felt by touching the glazing material. The second

form of heat transfer is radiation; electromagnetic waves carry heat through a

glazing. This produces the feeling of heat radiating from the surface of the

glazing. The third method of heat transfer is convection. Convection transfers

heat by motion, in this case, air flow. The natural flow of warm air toward

colder air allows heat to be lost or gained.

The R-value of a glazing - its insulating capabilities or resistance to the

flow of heat - is determined by the degree of conduction, radiation, and

convection through the glazing material. However, air infiltration will also

determine the overall R-value of a glazing system. The amount of heat that

travels around a glazing is as important as the heat transfer through a

glazing. Air can leak in or out of a building around the glazing via the

framing. The quality, workmanship, and the installation of the entire glazing

system, including the framing, affects air infiltration.

Advances in glass technology have perhaps been the single largest contributor

to building efficiency since the 1970s and they play an important roll in solar

design. Some window advances include:

![]() Double

and triple pane windows with much higher insulating values.

Double

and triple pane windows with much higher insulating values.

![]() Low

emissivity or Low-E glass employing a coating which lets heat in but not out.

Low

emissivity or Low-E glass employing a coating which lets heat in but not out.

![]() Argon

(and other) gas filled windows that increase insulating values above windows

with just air.

Argon

(and other) gas filled windows that increase insulating values above windows

with just air.

![]() Phase-change

technologies that can switch from opaque to translucent when a voltage is

applied to them.

Phase-change

technologies that can switch from opaque to translucent when a voltage is

applied to them.

Basic Glass Types

Glazing materials include glass, acrylics, fibreglass, and other materials.

Although different glazing materials have very specific applications, the use

of glass has proven the most diverse. The various types of glass allow the

passive solar designer to fine-tune a structure to meet client needs. The

single pane is the simplest of glass types, and the building block for higher

performance glass. Single panes have a high solar transmission, but have poor

insulation - the R-value is about 1,0. Single pane glass can be effective when

used as storm windows, in warm climate construction (unless air conditioning is

being used), for certain solar collectors, and in seasonal greenhouses.

Structures using single pane glass will typically experience large temperature

swings, drafts, increased condensation, and provide a minimal buffer from the

outdoors.

Perhaps the most common glass product used today is the double pane unit.

Double pane glass is just that: two panes manufactured into one unit. Isolated

glass (thermopane) incorporate a spacer bar (filled with a moisture absorbing

material called a desiccant) between the panes and are typically sealed with

silicone. The spacer creates a dead air space between the panes. This air space

increases the resistance to heat transfer; the R-value for double pane is about

1,8-2,1. Huge air spaces will not drastically increase R-value. In fact, a

large air space can actually encourage convective heat transfer within the unit

and produce a heat loss. A rule of thumb for air space is between 1 and 2

centimetres. It is also possible to go as large as 10-12 centimetres without

creating convective flow, but at that point you are dealing with a very large

and awkward unit. The demand for greater energy efficiency in building and

retrofitting homes has made insulated glass units the standard. With good solar

transmission and fair insulation, such unit is a large improvement over the

single pane. Windows, doors, skylights, sunrooms, and many other areas utilize

double pane glass.

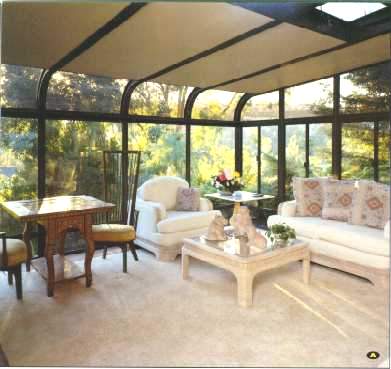

![]()

HIGH PERFORMANCE GLASS

High performance or enhanced glass offers even better R-value and solar

energy control. By further improving the insulating capability of glass, it is

possible dramatically increase also design options. What were once

insulated walls may become sunrooms. Solid roofs and ceilings become windows to

the sky. Dark rooms can “wake up” to natural light, solar heat gain, and

wonderful views. For a relatively small increase in cost it is possible to

improve efficiency, provide better moisture and UV protection, and gain design

flexibility. A variety of high performance glass is now available.

What are the advantages of this glass? Low emissivity (Low-E) glass is succeeding double pane glass in energy efficient buildings. Emissivity is the measure of infrared (heat) transfer through a material. The higher the emissivity, the more heat is radiated through the material. Conversely, the lower the emissivity, the more heat is reflected by the material. Low-E coatings will reflect, or re-radiate, the infrared heat back into a room, making the space warmer. This translates into R-values from 2.6 to 3.2. In warmer climates it is possible to reverse the unit and re-radiate infrared heat back to the outside, keeping the space cooler. Low-E glass improves the R-value, UV protection, and moisture control.Gas-filled windows increase R-value. Properly done, gas-filling will increase the overall R-value of a glass unit by about 1,0. The air within an insulated glass unit is displaced with an inert, harmless gas with better insulation properties. Typical gases used are Krypton and Argon.

Window curtains

In addition to decorative functions, curtains can be used to reduce the heat

losses that occur during the cold months as well as the heat gains during the

warmer months. The plywood box over the curtain top prevents warm ceiling air

from moving between the glass and curtain. The curtain should drop at least 30

cm below the window for it to be effective. The optimum condition would be for

it to drop to the floor.

Thermal mass

Solar radiation hitting walls, windows, roofs and other surfaces is adsorbed

by the building and is stored in thermal mass. This stored heat is then

radiated to the interior of the building. Thermal mass in a solar heating

system performs the same function as batteries in a solar electric system (see

chapter on photovoltaics). Both store solar energy, when available, for later

use.

Thermal mass can be incorporated into a passive solar room in many ways, from tile-covered floors to water-filled drums. Thermal mass materials, which include slab floors, masonry walls, and other heavy building materials, absorb and store heat. They are a key element in passive solar homes. Homes with substantial south-facing glass areas and no thermal storage mass do not perform well.

It is important to know that dark surfaces reflect less, therefore, absorb more heat. In case of a dark tiled floor, the floor will be able to absorb heat all day and radiate heat into the room at night. The rate of heat flow is based on the temperature difference between heat source and the object to which the heat flows. As described above heat flows in three ways - conduction (heat transfer through solid materials), convection (heat transfer through the movement of liquids or gasses), and radiation. All surfaces of a building lose heat via these three modes. Good solar design works to minimize heat loss and maximize efficient heat distribution. The need for thermal mass (heat-storage materials) inside a building is very climate-dependent. Heavy buildings of high thermal mass are consistently more comfortable during hot weather in hot-arid and cool-temperate climates, while in hot-humid climates there is little benefit. In cool-temperature climates the thermal mass acts as a cold-weather heat store thus improving overall comfort and reducing the need for auxiliary heating, except on overcast or very cold days. In intermittently heated buildings, however, it tends to increase the heat needed to maintain the chosen conditions.

Providing adequate thermal mass is usually the greatest challenge to the

passive solar designer. The amount of mass needed is determined by the area of

south-facing glazing and the location of the mass. In order to ensure an

effective design it is important to follow these guidelines:

![]() Locate the thermal mass in

direct sunlight. Thermal mass installed where the sun can reach it directly is more

effective than indirect mass placed where the sun's rays do not penetrate.

Houses that rely on indirect storage need three to four times more thermal mass

than those using direct storage.

Locate the thermal mass in

direct sunlight. Thermal mass installed where the sun can reach it directly is more

effective than indirect mass placed where the sun's rays do not penetrate.

Houses that rely on indirect storage need three to four times more thermal mass

than those using direct storage.

![]() Distribute the thermal mass.

Passive solar homes work better if the thermal mass is relatively thin and

spread over a wide area. The surface area of the thermal mass should be at

least 3 times, and preferably 6 times, greater than the area of the south

windows. Slab floors that are 8 to 10 centimetres thick are more cost effective

and work better than floors 16 to 20 inches thick.

Distribute the thermal mass.

Passive solar homes work better if the thermal mass is relatively thin and

spread over a wide area. The surface area of the thermal mass should be at

least 3 times, and preferably 6 times, greater than the area of the south

windows. Slab floors that are 8 to 10 centimetres thick are more cost effective

and work better than floors 16 to 20 inches thick.

![]() Do not cover the thermal mass.

Carpeting virtually eliminates savings from the passive solar elements. Masonry

walls can have drywall finishes, but should not be covered by large wall

hangings or lightweight panelling. The drywall should be attached directly to

the mass wall, not to covers fastened to the wall that create an undesirable

insulating airspace between the drywall and the mass.

Do not cover the thermal mass.

Carpeting virtually eliminates savings from the passive solar elements. Masonry

walls can have drywall finishes, but should not be covered by large wall

hangings or lightweight panelling. The drywall should be attached directly to

the mass wall, not to covers fastened to the wall that create an undesirable

insulating airspace between the drywall and the mass.

![]() Select an appropriate mass

colour. For best performance, finish mass floors with a dark colour. A medium

colour can store 70 percent as much solar heat as a dark colour, and may be

appropriate in some designs. A matte finish for the floor reduces reflected

sunlight, thus increasing the amount of heat captured by the mass and having

the additional advantage of reducing glare. The colour of interior mass walls

does not significantly affect passive solar performance.

Select an appropriate mass

colour. For best performance, finish mass floors with a dark colour. A medium

colour can store 70 percent as much solar heat as a dark colour, and may be

appropriate in some designs. A matte finish for the floor reduces reflected

sunlight, thus increasing the amount of heat captured by the mass and having

the additional advantage of reducing glare. The colour of interior mass walls

does not significantly affect passive solar performance.

![]() Insulate the thermal mass

surfaces. There are several techniques for insulating slab floors and masonry

exterior walls. These measures should introduced to achieve the energy

savings. Unfortunately, problems in some case can arise like with termite

infestations in foam insulation for perimeter slabs. This can complicate the

issue of whether and how to insulate slab-on-grade floors.

Insulate the thermal mass

surfaces. There are several techniques for insulating slab floors and masonry

exterior walls. These measures should introduced to achieve the energy

savings. Unfortunately, problems in some case can arise like with termite

infestations in foam insulation for perimeter slabs. This can complicate the

issue of whether and how to insulate slab-on-grade floors.

![]() Make thermal mass multipurpose.

For maximum cost effectiveness, thermal mass elements should serve other

purposes as well. Masonry thermal storage walls are one example of a passive

solar design that is often cost prohibitive because the mass wall is only

needed as thermal mass. On the other hand, tile-covered slab floors store heat,

serve as structural elements, and provide a finished floor surface. Masonry

interior walls provide structural support, divide rooms, and store heat.

Make thermal mass multipurpose.

For maximum cost effectiveness, thermal mass elements should serve other

purposes as well. Masonry thermal storage walls are one example of a passive

solar design that is often cost prohibitive because the mass wall is only

needed as thermal mass. On the other hand, tile-covered slab floors store heat,

serve as structural elements, and provide a finished floor surface. Masonry

interior walls provide structural support, divide rooms, and store heat.

![]()

When developing a thermal storage system or simply comparing materials it

is useful to look at the storage capacity of the proposed building materials

which is referred to as the volumetric heat capacity (J/m3. Deg. Celsius) or

more commonly the specific heat and the rate at which the material can take up

and store heat. Some examples of common storage materials are given in the

following table:

|

Material |

Density (kg/m3) |

Volumetric heat capacity (J/m3. Deg. C) |

|

Water |

1000 |

4186 |

|

Concrete |

2100 |

1764 |

|

Brick |

1700 |

1360 |

|

Stone: marble |

2500 |

2250 |

|

|

Materials not suitable for thermal storage |

|

|

Plasterboard |

950 |

798 |

|

Timber |

610 |

866 |

|

Glass fibre matt |

25 |

25 |

Early solar designers used water (stored in large containers) as the heat storage medium. Although water is cheap, the containers and the space they take are not. Some solar designers turned to rock storage bins as reservoirs for thermal mass. It took three times as much rock to store the same amount of heat as an equivalent volume of water and the moist warm environment of the bins became breeding grounds for odor producing fungi and bacteria. The high cost and the foul odors started to give solar design a bad name. Both water and rock heat storage require complicated control systems, pumps, and blowers. Heat storage is not common in today‘s solar energy utilisation. Main reason for this is that all of these systems rely on electricity, require maintenance, and are subject to periodic breakdown.

Thermal insulation

|

|

Materials generally available for building purposes can be classified into two generic groups - bulk materials and reflective foil laminates (RFL). The first of these relies on the resistance of air trapped in pockets between the fibres of the blanket type materials (mineral fibre materials) or the cells formed in the foamed structure of board or slab type materials (usually made from plastics such as polystyrene and polyurethane foams). The second reflects radiant energy away from the object or surface being protected. Thermal insulation in the outer fabric of a building is a vital component of an energy-efficient design strategy. The key to successful energy-efficient design is the control of heat flow through the external fabric. All the solar energy gained could be easily lost from an inadequately insulated building before it is able to be of benefit. It will have been noted that some materials have a very much higher thermal resistance per unit thickness than others irrespective of their density. The fact that air is a good insulator especially if it is bounded by a bright foil surface to limit radiation transfer can be very useful as well. |

Cooling

In many parts of the world a passive solar building needs cooling as much as

heating. One of the best, time proven methods of cooling is thermal coupling

with the earth's constant temperature. Dropping the ground floor at least one

meter into the earth provides a more even exterior temperature which aids

cooling as well as heating. Adequate structural engineering, drainage, and damp

proofing are essential in below ground areas. Thermal isolation is the best and

most economical way to temper the building's environment. Using the earth's

thermal mass keeps the house at a reasonable temperature, and so does good

insulation. Shades located outside and inside the windows, ventilation and

reflective films on the windows are also very important in order to control

temperature inside the building.

![]()

External Shades and Shutters

Exterior window shading treatments are effective cooling measures because

they block both direct and indirect sunlight outside of the home. Solar shade screens

are an excellent exterior shading product with a thick weave that blocks up to

70 percent of all incoming sunlight. The screens absorb sunlight so they should

be used on the exterior of the windows. From outside, they look slightly darker

than regular screening, but from the inside many people do not detect a

difference. Most products also serve as insect screening. They should be

removed in winter to allow full sunlight through the windows. A more expensive

alternative to the fibreglass product is a thin, metal screen that blocks

sunlight, but still allows a view from inside to outside. Hinged decorative

exterior shutters which close over the windows are also excellent shading

options. However, they obscure the view, block daylight completely, may be

expensive and may be difficult for many households to operate on a daily basis.

Interior Shades and Shutters

Shutters and shades located inside the house include curtains, roll-down

shades, and Venetian blinds. Interior shutters and shades are generally the

least effective shading measures because they try to block sunlight that has

already entered the room. However, if passive solar windows do not have

exterior shading, interior measures are needed. The most effective interior

treatments are solid shades with a reflective surface facing outside. In fact,

simple white roller blinds keep the house cooler than more expensive louvered

blinds, which do not provide a solid surface and allow trapped heat to migrate

between the blinds into the house.

Reflective Films and Tints

Reflective film, which adheres to glass and is found often in commercial

buildings, can block up to 85% of incoming sunlight. The film blocks sunlight

all year, so it is inappropriate on south windows in passive solar homes.

However, it may be practical for unshaded east and west windows. These films

are not recommended for windows that experience partial shading because they

absorb sunlight and heat the glass unevenly. The uneven heating of windows may

break the glass or ruin the seal between double-glazed units.

Ventilation

Ventilation is the changing of air in buildings to control oxygen, heat and

contaminants. Ventilation may occur in few forms. Building orientation, form,

plan and user actions also alter air flow paths. Natural ventilation consumes

no energy and has few if any running costs, but depends on weather conditions

and can be difficult to control. Mechanical and air-conditioned ventilation are

energy-driven alternatives to natural ventilation, normally dictated by

building type, site and function. They can be particularly efficient as

supplements to natural ventilation. Mechanical ventilation uses fans and ducts

to supply and extract air in localised areas such as a kitchen. Air

conditioning both treats and supplies air. It is particularly useful to cool

air below ambient temperatures.

SOLAR ARCHITECTURE &

ACTIVE SYSTEMS

It is important to design the house with the aim to incorporate active solar

systems (see below) like collectors or photovoltaic modules as well. The

building should orient these appliances due south. Tilt of the solar collectors

should be in Europe and North America more than 50° (from horizontal) to

maximize winter heat collection. Solar collectors should be thermally locked

with the roof. Non-tracking photovoltaics receive the most yearly insolation

(exposure to the sun's rays) when tilted at an angle, from horizontal, equal to

the building's latitude. Design of the building's roof should be done to such

angles and southern orientation as integral aspects of the building. Hot water

collectors and photovoltaic panels should be located as close as possible to

their main areas of use. It is important to concentrate these areas of use. For

example, putting the bathrooms and kitchen close together economizes on their

installation and minimizes energy loss. All appliances should be selected with

efficiency as the prime criterion.

![]()

SUMMARY

|

|

Passive use of sunlight contributes around 15% of space heating needs in typical building. It is important source of energy savings which can be utilised everywhere and almost at no extra cost. There are some principles which can help a designer to harness solar energy through thermally efficient buildings. |

SITE

It is important to become familiar with the energy flows of house

surroundings. The nature and relationship of the lay of the land, water

courses, vegetation, soil types, wind directions, and exposure to the sun

should be investigated. A site suitable for solar design should balance and

complement these elements. It must have unobstructed exposure to the sun from 9

am to 3 pm during the heating season.

HEATING

In Northern hemisphere orientation due south of the main solar insolating

spaces, i.e. greenhouse, and/or main daytime activity areas is important. Glass

should be open to the sun patterns during the winter. By facing of the windows

to the south, and virtually none to the north maximaze solar gain. Multiple

pane glass in all windows is recommended.

THERMAL MASS

Thermal mass including masonry floors, walls and water storage is important

to absorb ambient heat during the day and release it at night. Insulation of

the building further minimize heat loss through windows, walls and roof.

NATURAL HEAT FLOW

It is useful to design the house with the natural heat flow in mind. Hot air

rises, so placing some activity areas on a second floor to draw heat up

from a lower collector area and across other areas can save a lot of energy.

Buffer areas of the building (unheated rooms, or partially heated spaces such

as utility rooms, vestibules and storage areas) should be oriented due to the north

to lessen the impact of the winter's cold. Using a vestibule on doors to the

exterior can lead to energy savings. Vestibules cut heat loss and provide a

buffer zone between the exterior and the interior.

Using energy from the sun to heat water is one of the

oldest uses of solar energy. Solar collectors are the heart of most solar energy

systems. The collector absorbs the sun's light energy and changes it into heat

energy. This energy is than transferred to a fluid or air which are used to

warm buildings, heat water, generate electricity, dry crops or cook food. Solar

collectors can be used for nearly any process that requires heat.

Domestic hot water is the second-highest energy cost in the typical

household in Europe or North America. In fact, for some homes it can be the

highest energy expenditure. Solar water heating can reduce domestic water

heating costs by as much as 70%. Designed to pre-heat the domestic water that

is supplied to conventional water collector, it can result in remarkable savings.

It's easy to install and almost maintenance free.

Today, solar water heating systems are being used for single family houses,

apartment buildings, schools, car washes, hospitals, restaurants,

agricultural farms and different industries. This is a diverse list of private,

commercial and industrial buildings, but they all have one thing in common

- they all use hot water. Owners of these buildings have found that

solar water heating systems are cost-effective in meeting their hot water needs

all over the world.

![]()

HISTORY

Solar water heating was used long before fossil fuels dominated our energy

system. The principles of solar heat have been known for thousands of years. A

black surface gets hot in the sun, while a lighter coloured surface remains

cooler, with white being the coolest. This principle is used by solar water collectors

which are one of the best known applications for the direct use of the sun's

energy. They were developed some two hundred years ago and the first known flat

plate collector was made by Swiss scientist Horace de Saussure in 1767, later

used by Sir John Herschel to cook food during his South Africa expedition in

the 1830's.

Solar technology advanced to roughly it's present design in 1908 when

William J. Bailey of the Carnegie Steel Company (USA), invented a

collector with an insulated box and copper coils. This collector was very

similar to the thermosyphon system (described bellow). Bailey sold 4000

units by the end of World War I and a Florida businessperson who bought the

patent rights sold nearly 60 000 units by 1941. In the U.S. the rationing of

copper during World War II sent the solar water heating market into a sharp

decline.

Little interest was shown in such devices until the world-wide oil crisis of

1973. This crisis promoted new interest in alternative energy sources. As a

result, solar energy has, received increased attention and many countries are

taking a keen interest in new developments. The efficiency of solar heating

systems and collectors has improved from the early 1970s. The efficiencies can

be attributed to the use of low-iron, tempered glass for glazing (low-iron

glass allows the transmission of more solar energy than conventional glass),

improved insulation, and the development of durable selective coatings.

SOLAR COLLECTOR MARKET

Solar domestic hot-water

systems are technically mature and available practically all over the world.

The market for flat-type collectors has been reported as substantial in Israel,

China, Cyprus, Japan, Australia, Austria, Germany, Greece Turkey and USA. Sales

in Europe are mainly for domestic water heating, which may also include space

heating and heating swimming pools. World production of solar collectors in

1995 was 1,3 million m2 where market in Europe and Mediterranean countries is

reported to be about 40% of the world market. Total amount of installed solar

collectors exceeded 30 million m2 and the development of sales was very rapid

since 1980. Since 1989 there is steady increase with around 20 % per year.

Solar domestic hot-water

systems are technically mature and available practically all over the world.

The market for flat-type collectors has been reported as substantial in Israel,

China, Cyprus, Japan, Australia, Austria, Germany, Greece Turkey and USA. Sales

in Europe are mainly for domestic water heating, which may also include space

heating and heating swimming pools. World production of solar collectors in

1995 was 1,3 million m2 where market in Europe and Mediterranean countries is

reported to be about 40% of the world market. Total amount of installed solar

collectors exceeded 30 million m2 and the development of sales was very rapid

since 1980. Since 1989 there is steady increase with around 20 % per year.

Among countries in Europe, Greece has become the leader in production of

solar systems and exports 40% of all collectors produced and comprises 30% of

the market in Germany. The industry‘s goal for the year 2005 represents

1,3 million systems and 5 million m2 of collectors. A project on Crete

will need 20,000 collectors over two years. The Greek market installs

70,000 solar systems a year, reducing CO2 emissions by 1,5 million tonnes.

Sales in the EU in 1996 were reported to be over 0,7 million m2 of glazed

collectors and about 0,15 million m2 of unglazed collectors (Renewable energy

world, Sept. 1998). All the indications are that this trend will continue at a

rapid pace since measures are being taken all over the EU for the promotion of

solar systems.

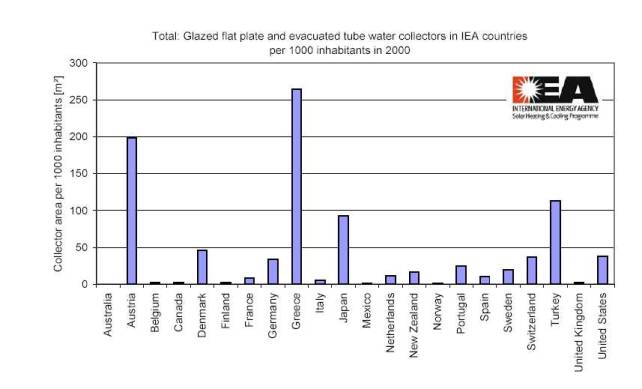

Installed solar collector area in the world (Source: IEA SHC programme: Solar Thermal Collector Market in IEA Member Countries, December 2002)

Installed solar collector area per head of population was 0,5 m2 in Cyprus in 2002 the largest in Europe and followed by Greece and Austria. Collector area per head of population increased in Austria up to 0,2 m2 in 2002 and amounted total area of 1,5 million m2. Austria is first in sales per capita followed by Greece but both countries still fall behind the world leaders Israel and Cyprus. Analysis of statistical figures like collector area per head of population shows that favourable climatic conditions have less influence than socio-economic boundary conditions. The success in Cyprus is explained not only by the absence of any other local source of energy but also by countries regulation. Strong legislation promoting solar energy utilisation is in force also in Israel. Israel and Cyprus have imposed statutory requirements for solar heating systems in all new buildings. These requirements were introduced in stages: thus in Israel initially all new apartment buildings of up to eight storeys were required to have a community solar water heating system with appropriate storage tanks. This was later extended to all new dwellings in the country. Finally in 1983 new regulations required hotels, hospitals and schools to install solar water heating equipment. These regulations were coupled with financial incentives. A similar attempt has also been made in Cyprus and it was recently estimated that 90 % of individual dwellings and 15 % of apartments in Cyprus are now equipped with solar water heaters.

POTENTIALS

In Europe the total rapidly exploitable potential for solar collectors

production is estimated to be 360 million m2 , representing a market volume of

50 billion USD at an annual average growth rate of 23%. In 2005 the area

occupied by glazed solar collector installations in the EU was expected to rise

to 28 million m2. Moreover, unglazed solar collectors for heating swimming

pools are expected to reach 20 million m2.

![]()

SOLAR COLLECTORS TYPES

Typical solar collectors collect the sun's energy usually with rooftop

arrays of piping and net metal sheets, painted black to absorb as much

radiation as possible. They are encased in glass or plastic and angled towards south

to catch maximum sunshine. The collectors act as miniature greenhouses,

trapping heat under their glass plates. Because solar radiation is so diffuse,

the collectors must have a large area.

Solar collectors can be made in various sizes and constructions depending

on requirements. They give enough hot water for washing, showers and cooking.

They can be used also as pre-heaters for existing water heaters. Today there

are several collectors on the market. They can be divided into several

categories. One of them is division according temperature they produce:

![]() Low-temperature collectors

provide low grade heat, less than 50 degrees Celsius, through either metallic

or non-metallic absorbers for applications such as swimming pool heating and

low-grade water.

Low-temperature collectors

provide low grade heat, less than 50 degrees Celsius, through either metallic

or non-metallic absorbers for applications such as swimming pool heating and

low-grade water.

![]() Medium-temperature collectors

provide medium to high-grade heat (greater than 50 degrees Celsius, usually 60

to 80 degrees), either through glazed flat-plate collectors using air or liquid

as the heat transfer medium or through concentrator collectors that concentrate

the heat to levels greater than “one sun.” These include evacuated tube

collectors, and are most commonly used for residential hot water heating.

Medium-temperature collectors

provide medium to high-grade heat (greater than 50 degrees Celsius, usually 60

to 80 degrees), either through glazed flat-plate collectors using air or liquid

as the heat transfer medium or through concentrator collectors that concentrate

the heat to levels greater than “one sun.” These include evacuated tube

collectors, and are most commonly used for residential hot water heating.

![]() High-temperature collectors are

parabolic dish or trough collectors primarily used by independent power

producers to generate electricity for the electric grid.

High-temperature collectors are

parabolic dish or trough collectors primarily used by independent power

producers to generate electricity for the electric grid.

Batch Solar Water Collectors

|

|

The simplest type of solar water collector is a “batch” collector, so called because the collector is the storage tank - water is heated and stored a batch at a time. Batch collectors are used as pre-heaters for conventional or instantaneous water heaters. When hot water is used in the household, solar-preheated water is drawn into the conventional water collector. Since the water has already been heated by the sun, this reduces energy consumption. A batch solar water collector is a low cost alternative to an active solar hot water system, offering no moving parts, low maintenance, and zero operational cost. The acronym for a batch type solar water collector is ICS, meaning Integrated Collector and Storage. Batch collectors, also known as “breadbox” , use one or more black tanks filled with water and placed in an insulated, glazed box. Some boxes include reflectors to increase the solar radiation. Solar energy passes through the glazing and heats the water in the tanks. These devices are inexpensive solar water collectors but must be drained or protected from freezing when temperatures drop below freezing. |

Flat-Plate Collectors

Flat-plate collectors are the

most common collectors for residential water heating and space-heating installations.

A typical flat-plate collector is an insulated metal box with a glass or

plastic cover called the glazing and a dark-coloured absorber plate. The

glazing can be transparent or translucent. Translucent (transmitting light

only) low-iron glass is a common glazing material for flat-plate collectors

because low-iron glass transmits a high percentage of the total available solar

energy. The glazing allows the light to strike the absorber plate but reduces

the amount of heat that can escape. The sides and bottom of the collector are

usually insulated, further minimising heat loss.

Flat-plate collectors are the

most common collectors for residential water heating and space-heating installations.

A typical flat-plate collector is an insulated metal box with a glass or

plastic cover called the glazing and a dark-coloured absorber plate. The

glazing can be transparent or translucent. Translucent (transmitting light

only) low-iron glass is a common glazing material for flat-plate collectors

because low-iron glass transmits a high percentage of the total available solar

energy. The glazing allows the light to strike the absorber plate but reduces

the amount of heat that can escape. The sides and bottom of the collector are

usually insulated, further minimising heat loss.

The absorber plate is usually black because dark colours absorb more solar

energy than light colours. Sunlight passes through the glazing and strikes the

absorber plate, which heats up, changing solar radiation into heat energy. The

heat is transferred to the air or liquid passing through the flow tubes.

Because most black paints still reflect approximately 10% of the incident radiation

some absorber plates are covered with “selective coatings,” which retain the

absorbed sunlight better and are more durable than ordinary black paint. The

selective coating used in the collector consists of a very precise thin layer

of an amorphous semiconductor plated on to a metal substratum. Selective

coatings has both high absorptivity in the visible region and low emissivity in

the long-wave infrared region.

Absorber plates are often made of metal usually copper or aluminium because

they are both good heat conductors. Copper is more expensive, but is a better

conductor and is less prone to corrosion than aluminium. An absorber plate must

have high thermal conductivity, to transfer the collected energy to the water

with minimum temperature loss. Flat-plate collectors fall into two basic categories:

liquid and air. And both types can be either glazed or unglazed.

![]()

Liquid Collectors

In a liquid collector, solar

energy heats a liquid as it flows through tubes in the absorber plate. For this

type of collector, the flow tubes are attached to the absorber plate so the

heat absorbed by the absorber plate is readily conducted to the liquid.

In a liquid collector, solar

energy heats a liquid as it flows through tubes in the absorber plate. For this

type of collector, the flow tubes are attached to the absorber plate so the

heat absorbed by the absorber plate is readily conducted to the liquid.

The flow tubes can be routed in parallel, using inlet and outlet headers, or

in a serpentine pattern. A serpentine pattern eliminates the possibility of

header leaks and ensures uniform flow. A serpentine pattern can pose some

problems for systems that must drain for freeze protection because the curved

flow passages will not drain completely.

The simplest liquid systems use potable household water, which is heated as

it passes directly through the collector and then flows to the house to be used

for bathing, laundry, etc. This design is known as an “open-loop” (or “direct”)

system. In areas where freezing temperatures are common, however, liquid

collectors must either drain the water when the temperature drops or use an

antifreeze type of heat-transfer fluid.

In systems with heat-transfer fluids, the transfer fluid absorbs heat from

the collector and then passes through a heat exchanger. The heat exchanger,

which generally is in the water storage tank inside the house, transfers heat to

the water. Such designs are called “closed-loop” (or “indirect”) systems.

Glazed liquid collectors are used for heating household water and sometimes

for space heating. Unglazed liquid collectors are commonly used to heat water

for swimming pools. Because these collectors need not withstand high

temperatures, they can use less expensive materials such as plastic or rubber.

They also do not require freeze-proofing because swimming pools are generally

used only in warm weather.

Air Collectors

Air collectors have the advantage of eliminating the freezing and boiling

problems associated with liquid systems. Although leaks are harder to detect

and plug in an air system, they are also less troublesome than leaks in a

liquid system. Air systems can often use less expensive materials, such as

plastic glazing, because their operating temperatures are usually lower than

those of liquid collectors.

Air collectors are simple, flat-plate collectors used primarily for space

heating and drying crops. The absorber plates in air collectors can be metal

sheets, layers of screen, or non-metallic materials. The air flows through the

absorber by natural convection or when forced by a fan. Because air conducts

heat much less readily than liquid does, less heat is transferred between the

air and the absorber than in a liquid collector. In some solar air-heating

systems, fans on the absorber are used to increase air turbulence and improve

heat transfer. The disadvantage of this strategy is that it can also increase

the amount of power needed for fans and, thus, increase the costs of operating

the system. In colder climates, the air is routed between the absorber plate

and the back insulation to reduce heat loss through the glazing. However, if

the air will not be heated more than 17°C above the outdoor temperature, the air

can flow on both sides of the absorber plate without sacrificing efficiency.

The best features of air collector systems are simplicity and reliability.

The collectors are relatively simple devices. A well-made blower can be

expected to have a 10 to 20 year life span if properly maintained, and the

controls are extremely reliable. Since air will not freeze, no heat exchanger

is required.

However, the use of solar air heating collectors is still limited to supply

hot air for space heating and for drying of agricultural products mainly in

developing countries. The major limitations for the wide adoption of solar air

heaters are the high cost for commercially produced solar air heaters, the

large collector area required due to the low density and the low specific heat

capacity of the air compared to liquid heat transfer fluids, the extended air

duct system required, the high power requirement for forcing the air through

the collector, and the difficulty of heat storage. In countries with

comparatively low insolation and extended periods of adverse weather,

supplementary heat is required which increases investment costs to a level

which limits its competitiveness to conventional heating systems. Promising

ways to reduce the collector cost are the integration of the collector into the

walls or roofs of buildings and the development of collectors which can be

constructed using prefabricated components.

Solar wall.

Heating with the solar wall .

![]()

HOW IT WORKS ?

Solar air heaters can be classified based on the mode of air circulation. In

the bare plate collector, which is the most simple solar air heater, the air

passes through the collector underneath the absorber. This kind of solar air

heater is only suitable for temperature rise between 3 - 5 deg. Celsius due to

the high convection and radiation losses at the surface. The top losses can be

reduced significantly by covering the absorber with a transparent material of

low transitivity for infrared radiation. The air flow occurs in this kind of

solar air heater either underneath the absorber or between absorber and

transparent cover. Due to the transparent cover, the incident radiation on the

absorber is reduced slightly, but due to the reduction of the convective heat

losses, temperature rise between 20 and 50 degrees Celsius can be achieved

depending on insolation and air flow rate. A further reduction of the heat

losses can be achieved if the air is made to pass above and underneath the

absorber since this doubles the heat transfer area. The heat losses due to

radiation will be reduced by this process due to lower absorber temperature.

However, there is simultaneous reduction in the absorptivity of the absorber

due to dust deposit if air flow is above or on both sides of the absorber.

Some solar air collectors eliminate the cost of the glazing, the metal box,

and the insulation. Such a collector is made of black, perforated metal. The

best heat transfer can be achieved by using porous material as absorber.

The sun heats the metal, and a fan pulls air through the holes in the metal,

which heats the air. For residential installations, these collectors are

available in different sizes. Typical collector 2,4-meter by 0,8-meter

panels are capable of heating 0,002 m3 per second of outside air. On a sunny

winter day, the panel can produce temperatures up to 28°C higher than the

outdoor air temperature. Transpired air collectors not only heat air, but also

improve indoor air quality by directly preheating fresh outdoor air. These

collectors have achieved very high efficiencies - more than 70% in some

commercial applications. Plus, because the collectors require no glazing or

insulation, they are inexpensive to manufacture.

Evacuated-Tube Collectors

Conventional simple flat-plate

solar collectors were developed for use in sunny and warm climates. Their

benefits are greatly reduced when conditions become unfavourable during cold,

cloudy and windy days. Furthermore, weathering influences such as condensation

and moisture will cause early deterioration of internal materials resulting in

reduced performance and system failure. These shortcomings are reduced in

evacuated-tube collectors.

Conventional simple flat-plate

solar collectors were developed for use in sunny and warm climates. Their

benefits are greatly reduced when conditions become unfavourable during cold,

cloudy and windy days. Furthermore, weathering influences such as condensation

and moisture will cause early deterioration of internal materials resulting in

reduced performance and system failure. These shortcomings are reduced in

evacuated-tube collectors.

Evacuated-tube collectors heat water in residential applications that

require higher temperatures. In an evacuated-tube collector, sunlight enters

through the outer glass tube, strikes the absorber tube, and changes to heat.

The heat is transferred to the liquid flowing through the absorber tube. The

collector consists of rows of parallel transparent glass tubes, each of which

contains an absorber tube (in place of the absorber plate in a flat-plate

collector) covered with a selective coating. The heated liquid circulates

through heat exchanger and gives off its heat to water that is stored in a

solar storage tank.

Evacuated tube collectors are modular tubes which can be added or removed as

hot-water needs change. When evacuated tubes are manufactured, air is evacuated

from the space between the two tubes, forming a vacuum. Conductive and

convective heat losses are eliminated because there is no air to conduct heat

or to circulate and cause convective losses. There can still be some radiant

heat loss (heat energy will move through space from a warmer to a cooler surface,

even across a vacuum). However, this loss is small and of little importance

compared with the amount of heat transferred to the liquid in the absorber

tube. The vacuum in the glass tube, being the best possible insulation for a

solar collector, suppresses heat losses and also protects the absorber plate

and the “heat-pipe” from external adverse conditions. This results in

exceptional performance far superior to any other type of solar collector.

Evacuated-tube collectors are available in a number of

designs. Some use a third glass tube inside the absorber tube or other

configurations of heat-transfer fins and fluid tubes. One commercially

available evacuated-tube collector stores 19 litres of water in each tube,

eliminating the need for a separate solar storage tank. Reflectors placed

behind the evacuated tubes can help to focus additional sunlight on the

collector.

Due to the atmospheric pressure and the technical problems related to the

sealing of the collector casing, the construction of an evacuated flat-plate

collector is extremely difficult. To overcome the enormous atmospheric

pressure, many internal supports for the transparent cover pane must be

introduced. However, the problems of an effective high vacuum system with

reasonable production costs remain so far unsolved. It is more feasible to

apply and adapt the mature technology related to the lamp industries with

proven mass production. Building a tubular evacuated solar collector and the

maintenance of its high vacuum, similar to light bulbs and TV tubes, is

practical. The ideal vacuum insulation of the tubular evacuated solar

collector, obtained by means of a suitable exhausting process, has to be

maintained during the life of the device to reduce the thermal losses through

the internal gaseous atmosphere (convection losses).

In high temperature region these collectors are more efficient than

flat-plate collectors for a couple of reasons. First, they perform well in both

direct and diffuse solar radiation. This characteristic, combined with the fact

that the vacuum minimizes heat losses to the outdoors, makes these collectors

particularly useful in areas with cold, cloudy winters. Second, because of the

circular shape of the evacuated tube, sunlight is perpendicular to the absorber

for most of the day. For comparison, in a flat-plate collector that is in a

fixed position, the sun is only perpendicular to the collector at noon. Evacuated-tube

collectors achieve both higher temperatures and higher efficiencies than

flat-plate collectors, but they are also more expensive.

![]()

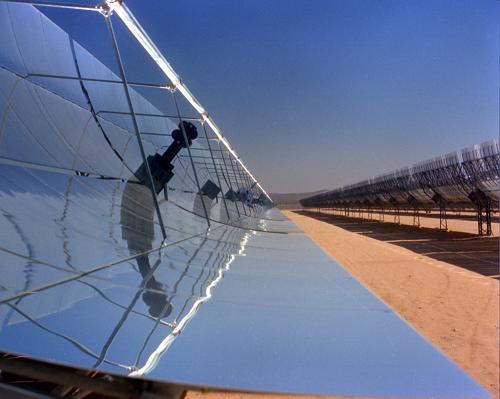

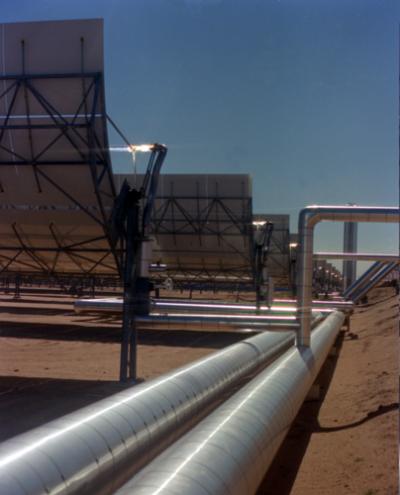

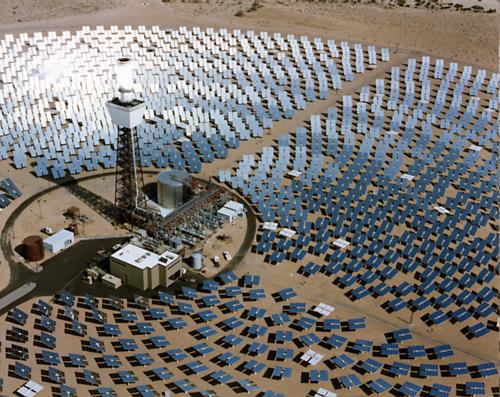

Concentrating Collectors

Concentrating collectors use mirrored surfaces to concentrate the sun's

energy on an absorber called a receiver. They also achieve higher temperatures

than flat-plate collectors, however concentrators can only focus direct solar

radiation, with the result being that their performance is poor on hazy or

cloudy days. The mirrored surface focuses sunlight collected over a large area

onto a smaller absorber area to achieve high temperatures. Some designs concentrate

solar energy onto a focal point, while others concentrate the sun's rays along

a thin line called the focal line. The receiver is located at the focal point

or along the focal line. A heat-transfer fluid flows through the receiver and

absorbs heat. Concentrators are most practical in areas of high insolation,

such as those close to the equator and in the desert areas.

Concentrators perform best when pointed directly at the sun. To do this,

these systems use tracking mechanisms to move the collectors during the day to

keep them focused on the sun. Single-axis trackers move east to west; dual-axis

trackers move east and west and north and south (to follow the sun throughout

the year). Concentrators are used mostly in commercial applications because

they are expensive and because the trackers need frequent maintenance. Some

residential solar energy systems use parabolic-trough concentrating systems.

These installations can provide hot water, space heating, and water

purification. Most residential systems use single-axis trackers, which are less

expensive and simpler than dual-axis trackers. For more information about

concentrating collectors see chapter Solar Thermal Power Production.

SOLAR COOKERS AND STILLS

There exists also some other inexpensive, “low-tech” solar collectors with

specific functions like solar box cookers (used for cooking) and solar stills

producing inexpensive distilled water from virtually any water source.

Solar box cookers (see chapter on Solar cooking) are inexpensive to buy and

easy to build and use. They consist of a roomy, insulated box lined with

reflective material, covered with glazing, and fitted with an external

reflector. Black cooking pots serve as absorbers, heating up more quickly than

aluminium or stainless steel cookware. Box cookers can also be used to kill

bacteria in water if the temperature can reach the boiling point.

Solar stills (see chapter on Solar water distillation) provide inexpensive

distilled water from even salty or badly contaminated water. They work on the

principle that water in an open container will evaporate. A solar still uses

solar energy to speed up the evaporation process. The stills consist of an

insulated, dark-coloured container covered with glazing that is tilted so the

condensing fresh water can trickle into a collection trough. A small solar

still, which is about the size of kitchen stove, can produce up to ten litres

of distilled water on a sunny day.

Technology Examples

Solar energy has a variety of practical and cost-effective applications in

today's homes and buildings. The main applications of solar collectors are as

follows :

![]() hot water preparation in

households, commercial buildings and industry,

hot water preparation in

households, commercial buildings and industry,

![]() water heating in swimming

pools,

water heating in swimming

pools,

![]() space heating in buildings,

space heating in buildings,

![]() drying crops and houses,

drying crops and houses,

![]() space cooling and

refrigeration,

space cooling and

refrigeration,

![]() water distillation,

water distillation,

![]() solar cooking.

solar cooking.

The technologies for all applications are considered to be mature and for

the first two, under the appropriate conditions, economically viable. Separate

chapter is devoted to concentrating collectors which are cost effectively used

for power production especially in regions with high insolation (see chapter on

Solar Thermal Power).

![]()

Solar Thermal Residential Water Heating

Today, several million homes and businesses use solar

water heating systems. These systems are providing consumers a cost-effective

and reliable choice for hot water. Taking a shower with solar-heated water, or

heating a house with solar-heated air or water, is a natural and simple method

for both conserving energy and saving fossil fuels. When a solar heating system

has been designed and installed correctly, it can be aesthetically appealing

and also add to the value of the home. On new construction, they can be worked

into the building design to be almost invisible, while on existing construction

it can be a real challenge to make them fit in.

A solar water collector is saving an owner money but it also help protect

the environment. Emissions of one to two tons of carbon dioxide are saved by a

single conventional water collector every year. Other pollutants, such as

sulphur dioxides, carbon monoxide and nitrous oxides are also displaced when a

homeowner decides to tap into a solar energy.

Hot water production is the most widely distributed utilisation of direct solar heating. An installation consists of one or more collectors in which a fluid is heated by the sun, plus a hot-water tank where the water is heated by the hot liquid. Even in the areas of low insolation like in Northern Europe a solar heating system can provide 50-70% of the hot water demand. It is not possible to obtain more, unless there is a seasonal storage (see chapter below). In Southern Europe a solar collector is able to cover 70-90% of the hot-water consumption. Heating water with the sun is very practical and cost effective. While photovoltaics (see chapter on photovoltaics) range from 10-15% efficiency, thermal water panels range from 50-90% efficiency. In combination with a wood stove coil/loop, virtually year round domestic hot water can be obtained without the use of fossil fuels.

HOW IS A SOLAR WATER

COLLECTOR COMPETITIVE WITH CONVENTIONAL HEATERS ?

Costs of complete solar water heating systems differs considerably from

country to country (in Europe and the USA e.g. between 2000 - 4000 USD). They

also depend on hot water requirements and the climate conditions in the area.

This is usually a higher initial investment than required for an electric or

gas heater but when adding all of the costs involved with heating water in

home, the life-cycle cost of a solar water heating system is usually lower than

traditional heating system. It must be noted that simple pay-back time for

investment into solar heating system depends on prices of fossil fuels

substituted by solar energy. In EU countries pay-back times are generally less

than 10 years. The expected life span of the solar heating system is 20-30

years.

Important feature of solar installation is energy pay-back time - time

needed to produce as much energy by solar system as it was needed to produce

this system. In Northern Europe with less solar radiation than in other parts

of the world a solar heating system for hot-water preparation has an energy pay

back period of 3-4 years.

HOW MUCH ENERGY CAN WE GET ?

The amount of energy we can get from solar heating system depends on

available insolation and efficiency of the solar system. Insolation differs

widely in the world and is crucial for solar system. The amount of solar

radiation available in some regions of the world is given in chapter Solar

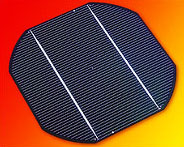

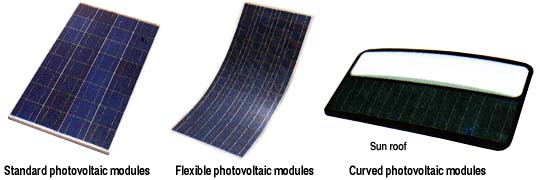

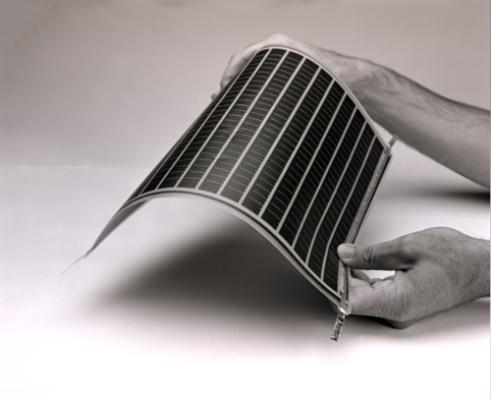

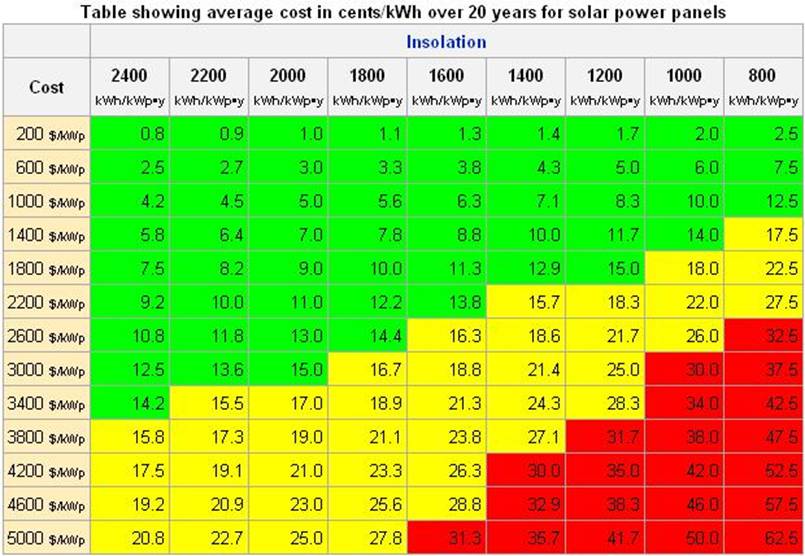

Radiation. The efficiency of solar system depends on efficiency of solar