|

|

|

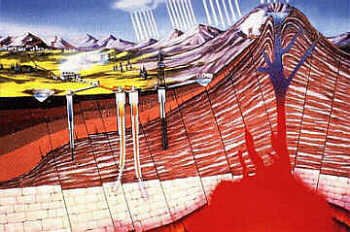

NATURE OF GEOTHERMAL RESOURCES

The Earth's thermal engine

The heat inside the Earth core is continually

generated by the decay of the longlived

radioactive isotopes of uranium, thorium

and potassium, which are present in the Earth. Added to this heat, there

are other potential sources of heat such as the primordial energy of planetary

accretion.

The

heat generated in theEarth's interior and the heat dissipated into space

from the Earth seems to be not in equilibrium. According to the theory

our planet is cooling down. The cooling process is, however, very slow.

The temperature of the mantle (see the picture above) has decreased no

more than 300-350°C in three billion years, remaining at about 4000°C at

its base. Estimates from more than twenty years ago gave the total heat

content of the Earth, reckoned above an assumed average surface temperature

of 15 °C, in the order of 12.6 x10E24 MJ, and that of the crust in the

order of 5.4 x 10E21 MJ. The thermal energy of the Earth is therefore immense,

but only a fraction can be utilized by man. So far our utilization of this

energy has been limited to areas in which geological conditions permit

a carrier (water in the liquid phase or steam) to "transfer" the heat from

deep hot zones to or near the surface, thus giving rise to geothermal resources,

but innovative techniques in the near future may offer new perspectives

in this sector.

The

heat generated in theEarth's interior and the heat dissipated into space

from the Earth seems to be not in equilibrium. According to the theory

our planet is cooling down. The cooling process is, however, very slow.

The temperature of the mantle (see the picture above) has decreased no

more than 300-350°C in three billion years, remaining at about 4000°C at

its base. Estimates from more than twenty years ago gave the total heat

content of the Earth, reckoned above an assumed average surface temperature

of 15 °C, in the order of 12.6 x10E24 MJ, and that of the crust in the

order of 5.4 x 10E21 MJ. The thermal energy of the Earth is therefore immense,

but only a fraction can be utilized by man. So far our utilization of this

energy has been limited to areas in which geological conditions permit

a carrier (water in the liquid phase or steam) to "transfer" the heat from

deep hot zones to or near the surface, thus giving rise to geothermal resources,

but innovative techniques in the near future may offer new perspectives

in this sector.

The geothermal gradient expresses the increase in temperature with depth in the Earth's crust. Down to the depths accessible by drilling with modern technology, the average geothermal gradient is about 2.5-3 °C/100 m. For example, if the temperature within the first few metres below ground-level, which on average corresponds to the mean annual temperature of the external air, is 15 °C, then we can reasonably assume that the temperature will be about 65°-75 °C at 2000 m depth, 90°-105 °C at 3000 m and so on for a further few thousand metres.

There are, however, vast areas in which the geothermal gradient is far from the average value. In areas in which the deep rock basement has undergone rapid sinking, and the basin is filled with geologically "very young" sediments, the geothermal gradient may be lower than 1 °C/100 m. On the other hand, in some "geothermal areas" the gradient is even higher than ten times the average value.

Our planet consists of a crust, which reaches a thickness of about 20-65 km in continental areas and about 5-6 km in oceanic areas, a mantle, which is roughly 2900 km thick, and a core, about 3470 km in radius.

The Earth's crust, mantle, and core.

Top right: a section through the crust and

the uppermost mantle.

The physical and chemical characteristics of the crust, mantle and core vary from the surface of the Earth to its centre. The outermost shell of the Earth, known as the lithosphere, is made up of the crust and the upper layer of the mantle. Ranging in thickness from less than 80 km in oceanic zones to over 200 km in continental areas, the lithosphere behaves as a rigid body. Below the lithosphere is the zone known as the asthenosphere, 200-300 km in thickness, and of a "less rigid" or "more plastic" behaviour. In other words, on a geological scale, where time is measured in millions of years, this part of the Earth behaves in much the same way as a fluid in certain processes.

Because of the difference in temperature between the different parts of the asthenosphere, convective movements and, possibly, convective cells were formed some tens of millions of years ago. Their extremely slow movement (a few centimetres per year) is maintained by the heat produced continually by the decay of the radioactive elements and the heat coming from the deepest parts of the Earth. Immense volumes of deep, hotter rocks, less dense and lighter than the surrounding material, rise with these movements towards the surface, while the colder, denser and heavier rocks near the surface tend to sink, re-heat and rise to the surface once again, very similar to what happens to water boiling in a pot or kettle.

In zones where the lithosphere is thinner,

and especially in oceanic areas, the lithosphere is pushed upwards and

broken by the very hot, partly molten material ascending from the asthenosphere,

in correspondence to the ascending branch of convective cells. It is this

mechanism that created and still creates the spreading ridges that extend

for more than

60,000 km beneath the oceans, emerging in

some places (Azores, Iceland) and even creeping between continents, as

in the Red Sea. A relatively tiny fraction of the molten rocks upwelling

from the asthenosphere emerges from the crests of these ridges and, in

contact with the seawater, solidifies to form a new oceanic crust.

Schematic cross-section showing plate tectonic

processes.

Spreading ridges, transform faults and subduction

zones form a vast network that divides

our planet into six immense and several other

smaller lithospheric areas or plates.

Because of the huge tensions generated by

the Earth's thermal engine and the asymmetry of the zones producing and

consuming lithospheric material, these plates drift slowly up against one

another, shifting position continually. The margins of the plates correspond

to weak, densely fractured zones of the crust, characterized by an intense

seismicity, by a large number of volcanoes and, because of the ascent of

very hot materials towards the surface, by a high terrestrial heat flow.

The most important geothermal areas are located around plate margins.

World pattern of plates, oceanic ridges, oceanic

trenches, subduction zones, and geothermal fields. Arrows show the direction

of movement of the plates towards the subduction zones. (1) Geothermal

fields producing electricity; (2) mid-oceanic ridges crossed by transform

faults (long transversal fractures); (3) subduction zones, where the subducting

plate bends downwards and melts in the asthenosphere.

| Geothermal Energy Cycle

Precipitation seeps deep into the earth where it is warmed by the earth's heat. In a few places, magma occurs close enough to the surface to heat fluids that can be reached by drilling wells. The hot water is then brought to the surface. In case of electricity production it is flashed to steam, and delivered by pipeline to electricity-generating plants. In instances where the geothermal reservoir produces natural steam, the steam is scrubbed to remove impurities before transmission to the power plant. Excess fluids are returned to the reservoir. |

|

HISTORY OF UTILISATION

In the early part of the nineteenth century

the geothermal fluids were already being exploited for their energy content.

A chemical industry was set up in that period in Italy, in the zone now

known as Larderello, to extract boric acid from the hot waters issuing

naturally or from specially drilled shallow boreholes. The boric acid was

obtained by evaporating the hot fluids in iron boilers, using the wood

from nearby forests as fuel. In 1827 Francesco Larderel, founder of this

industry, developed a system for utilizing the heat of the boric fluids

in the evaporation process, rather than burning wood from the rapidly depleting

forests. Exploitation of the natural steam for its mechanical energy began

at much the same time. The geothermal steam was used to raise liquids in

primitive gas lifts and later in reciprocating and centrifugal pumps and

winches, all of which were connected with drilling activity or in the local

boric acid industry. Between 1850 and 1875 the factory at Larderello held

the monopoly in Europe for boric acid production. Between 1910 and 1940

the low pressure steam in this area of Tuscany was brought into use to

heat the industrial and residential buildings and greenhouses.

In 1928 Iceland, another pioneer in the utilization of geothermal energy, also began exploiting its geothermal fluids (mainly hot waters) for domestic heating. The first attempt at generating electricity from geothermal steam was made at Larderello in 1904. The success of this experiment indicated the industrial value of geothermal energy and marked the beginning of a form of exploitation that was to develop significantly from then on.

Electricity generation at Larderello was a

commercial success. By 1942 the installed

geothermoelectric capacity had reached 127,65

MWe. The example set by Italy was followed by several countries. The first

geothermal wells in Japan were drilled at Beppu in 1919 and in the USA

at The Geysers, California, in 1921. In 1958 a small geothermal power plant

began operating in New Zealand, in 1959 in Mexico, in 1960 in the USA,

and in many other countries in the years to follow.

PRESENT STATUS

After the Second World War many countries

were attracted by geothermal energy,

considering it to be economically competitive

with other forms of energy. It did not have to be imported, and in some

cases, it was the only energy source available locally. The countries that

utilize geothermal energy to generate electricity are listed bellow, which

gives the installed geothermal electric capacity worldwide in 1995 (a world

total of 6833 MWe) and in the year 2000 (7974 MWe)

As regards non-electric applications of geothermal

energy, table bellow gives the installed capacity (15,145 MWt) and energy

use (190,699 TJ/yr) worldwide referred to the year 2000.

There are now 58 countries reporting direct

uses, compared to 28 in 1995 and 24 in 1985.

The data reported in this table are difficult

to collect and interpret, and should be used with caution. The most common

non-electric use worldwide (in terms of installed capacity) is heat pumps

(34.80%), followed by bathing (26.20%), space heating (21.62%), greenhouses

(8.22%), aquaculture (3.93%), and industrial processes (3.13%).

GEOTHERMAL SYSTEMS

Geothermal systems can be found in regions

with a normal or slightly above normal

geothermal gradient, and especially in regions

around plate margins where the geothermal gradients may be significantly

higher than the average value. In the first case the systems will be characterized

by low temperatures, usually no higher than 100 °C at economic depths;

in the second case the temperatures could cover a wide range from low to

very high, and even above 400 °C.

Geothermal system can be described schematically as "convecting water in the upper crust of the Earth, which, in a confined space,transfers heat from a heat source to a heat sink, usually the free surface". A geothermal system is made up of three main elements: a heat source, a reservoir and a fluid ,which is the carrier that transfers the heat. The heat source can be either a very high temperature (> 600 °C) magmatic intrusion that has reached relatively shallow depths (5-10 km) or, as in certain low temperature systems, the Earth's normal temperature, which increases with depth.

The reservoir is a volume of hot permeable rocks from which the circulating fluids extract heat. The reservoir is generally overlain by a cover of impermeable rocks and connected to a surficial recharge area through which the meteoric waters can replace or partly replace the fluids that escape from the reservoir by natural means (through springs, for example) or are extracted by boreholes. The geothermal fluid is water, in the majority of cases meteoric water, in the liquid or vapour phase, depending on its temperature and pressure. This water often carries with it chemicals and gases such as CO2,H2S, etc.

The mechanism underlying geothermal systems

is by and large governed by fluid

convection. Figure above describes schematically

the mechanism in the case of an intermediate temperature hydrothermal system.

Convection occurs because of the heating and consequent thermal expansion

of fluids in a gravity field; heat, which is supplied at the base of the

circulation system, is the energy that drives the system. Heated fluid

of lower density tends to rise and to be replaced by colder fluid of high

density, coming from the margins of the system. Convection, by its nature,

tends to increase temperatures in the upper part of a system as temperatures

in the lower part decrease.

Of all the elements of a geothermal system,

the heat source is the only one that need be

natural. Providing conditions are favourable,

the other two elements could be "artificial". For example, the geothermal

fluids extracted from the reservoir to drive the turbine in a geothermal

power-plant could, after their utilization, be injected back into the reservoir

through specific injection wells. In this way the natural recharge of the

reservoir is integrated by an artificial recharge. For many years now re-injection

has been adopted in various parts of the world as a means of drastically

reducing the impact on the environment of power-plant operations.

In the Hot Dry Rock (HDR) Project, implemented

in the USA in the early 1970s, both the fluid and the reservoir are artificial.

High-pressured water is pumped through a specially drilled well into a

deep body of hot, compact rock, causing its hydraulic fracturing. The water

permeates these artificial fractures, extracting heat from the surrounding

rock, which acts as a natural reservoir. This 'reservoir' is later penetrated

by a second well, which is used to extract the heated water. The system

therefore consists of :

1. the borehole used for hydraulic fracturing,

through which cold water is injected into

2. the artificial reservoir, and

3. the borehole used to extract the hot water.

The entire system, complete with surface utilization plant, could form a closed loop. This interesting project was eventually abandoned after a number of years of experiments as it proved too expensive and the results were not entirely satisfactory.

Geothermal energy is usually classified as

renewable and sustainable. Renewable

describes a property of the energy source,

whereas sustainable describes how the resource is utilized. The most critical

aspect for the classification of geothermal energy as a renewable energy

source is the rate of energy recharge. In the exploitation of natural geothermal

systems, the recharge of energy takes place by advection of thermal water

on the same time scale as production from the resource. This justifies

classification of geothermal energy as a renewable energy resource. In

the case of hot, dry rocks, and some of the hot water aquifers in sedimentary

basins, energy recharge is only by thermal conduction; due to the slowness

of the latter process, however, hot dry rocks and some sedimentary reservoirs

should be considered as finite energy resources.The sustainability in consumption

of a resource is dependent on its initial quantity, its rate of generation

and its rate of consumption. Consumption can obviously be sustained over

any time period in which a resource is being created faster than it is

being depleted.

Direct heat uses

Direct heat use is one of the oldest, most

versatile and also the most common form of

utilization of geothermal energy. Space and

district heating, agricultural applications,

aquaculture and industrial uses are the best

known and most widespread forms of utilization, but other forms are already

in use or in the late planning stages.

Space and district heating have made great

progress in Iceland, where the total capacity

of the operating geothermal district heating

system had risen to about 1200 MWt by the end of 1999, but they are also

widely distributed in the East European countries, as well as

in the United States, China, Japan, France,

etc.

Simplified flow diagram of the geothermal

district heating system of Reykjavik.

Geothermal district heating systems are capital

intensive. The main costs are initial

investment costs , for production and injection

wells, downhole and transmission pumps,

pipelines and distribution networks, monitoring

and control equipment, peaking stations and storage tanks. Operating expenses,

however, are comparatively lower than in conventional systems, and consist

of pumping power, system maintenance, control and management. A crucial

factor in estimating the initial cost of the system is the thermal load

density, or the heat demand divided by the ground area of the district.

A high heat density determines the economic feasibility of a district heating

project, since the distribution network is expensive.

Some economic benefit can be achieved by combining

heating and cooling in areas where the climate permits. The load factor

in a system with combined heating and cooling would be higher than the

factor for heating alone, and the unit energy price would consequently

improve.

AGRICULTURE

The agricultural applications of geothermal

fluids consist of open-field agriculture and

greenhouse heating. Thermal water can be used

in open-field agriculture to irrigate and/or heat the soil. The greatest

drawback in irrigating with warm waters is that, to obtain any worthwhile

variation in soil temperature, such large quantities of water are required

at temperatures low enough to prevent damage to the plants that the fields

would be flooded. One possible solution to this problem is to adopt a subsurface

irrigation system coupled to a buried pipeline soil heating device. Heating

the soil in buried pipelines without the irrigation system could decrease

the heat conductivity of the soil because of the drop in humidity around

the pipes and consequent thermal insulation. The best solution seems to

be that of combining soil heating and irrigation. The chemical composition

of the geothermal waters used in irrigation must be monitored carefully

to avoid adverse effects on the plants.

The main advantages of temperature control

in agriculture are:

1. it prevents any damage ensuing from low

environmental temperatures,

2. it extends the growing season, increases

plant growth, and boosts production, and

3. it sterilizes the soil .

The most common application of geothermal energy

in agriculture is, however, in

greenhouse heating, which has been developed

on a large scale in many countries. The

cultivation of vegetables and flowers out-of-season,

or in an unnatural climate, can now draw on a widely experimented technology.

Various solutions are available for achieving optimum growth conditions,

based on the optimum growth temperature of each plant , and on the quantity

of light, on the CO2 concentration in the greenhouse environment, on the

humidity of the soil and air, and on air movement. The walls of the greenhouse

can be made of glass, fibreglass, rigid plastic panels or plastic film.

Glass panels are more transparent than plastic and will let in far more

light, but will provide less thermal insulation, are less resistant to

shocks, and are heavier and more expensive than the plastic panels. The

simplest greenhouses are made of single plastic films, but recently some

greenhouses have been constructed with a double layer of film separated

by an air space. This system reduces the heat loss through the walls by

30 -40%, and thus greatly enhances the overall efficiency of the greenhouse.

Greenhouse heating can be accomplished by forced circulation of air in heat exchangers, hot-water circulating pipes or ducts located in or on the floor, finned units located along the walls and under benches, or a combination of these methods. Exploitation of geothermal heat in greenhouse heating can considerably reduce their operating costs, which in some cases account for 35% of the product costs (vegetables, flowers, house-plants and tree seedlings).

INDUSTRIAL APPLICATIONS

The entire temperature range of geothermal

fluids, whether steam or water, can be

exploited for industrial applications. The

different possible forms of utilization include process heating, evaporation,

drying, distillation, sterilization, washing, de-icing, salt and chemical

extraction, as well as oil recovery. Industrial process heat has applications

in 19 countries, where the installations tend to be large and energy consumption

high. Examples include: concrete curing, bottling of water and carbonated

drinks, paper and vehicle parts production, oil recovery, milk pasteurization,

leather industry, chemical extraction, CO2 extraction, mushroom growing

and laundry use, salt extraction and diatomaceous earth drying, pulp and

paper processing, and borate and boric acid production.

Geothermaly heated road inJapan.

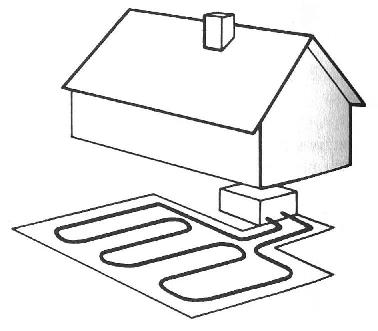

HEAT PUMPS

Geothermal space conditioning (heating and

cooling) has expanded considerably since the 1980s, following on the introduction

and widespread use of heat pumps. The various systems of heat pumps available

permit us to economically extract and utilize the heat content of lowtemperature

bodies, such as the ground and shallow aquifers, ponds, etc. The heat pumps

are machines that move heat in a direction opposite to that in which it

would tend to go naturally, i.e. from a cold space or body to a warmer

one. A heat pump is effectively nothing more than a refrigeration unit.

Any refrigeration device (window air conditioner, refrigerator, freezer,

etc.) moves heat from a space (to keep it cool) and discharges that heat

at higher temperatures. The only difference between a heat pump and a refrigeration

unit is the desired effect, cooling for the refrigeration unit and heating

for the heat pump. A second distinguishing factor of many heat pumps is

that they are reversible and can provide either heating or cooling in the

space.

Heat pumps.

Heat pumps need electricity to operate, but

in suitable climatic conditions and with a good design, the energy balance

is a positive one. Ground-coupled and ground-water heat pump systems are

being installed in great numbers in the United States, Switzerland and

Germany. Aquifers and soils at temperatures in the 5 to 30 °C range are

being used in these systems.

Geothermal power plants take advantage of energy which is tapped by drilling wells into the reservoirs and piping the steam or hot water to power plants, which convert the heat to electricity. Today's technology produces electricity from hydrothermal (hot water/steam) resources. In the future,it may be able to use the heat of the deep, hot, dry rock formations of Earth's crust, and possibly the even deeper, almost unlimited energy in Earth's magma.

Geothermal resources come in five forms:

![]() hydrothermal

fluids,

hydrothermal

fluids,

![]() hot

dry rock,

hot

dry rock,

![]() geopressured

brines,

geopressured

brines,

![]() magma,

and

magma,

and

![]() ambient

ground heat.

ambient

ground heat.

Of these five, only hydrothermal fluids have

been developed commercially for power generation.

Basic types of geothermal power plants used

today are :

![]() steam,

steam,

![]() high-temperature

water and

high-temperature

water and

![]() binary.

binary.

These three technologies can be used to convert hydrothermal fluids to electricity. The type of conversion used depends on the state of the fluid (whether steam or water) and its temperature:

Steam - Conventional steam turbines are used with hydrothermal fluids that are wholly or primarily steam. The steam is routed directly to the turbine, which drives an electric generator, eliminating the need for the boilers and fossil fuel of conventional power plants.

High-temperature water for hydrothermal fluids above 200° Celsius (C) that are primarily water, flash steam technology is usually employed. In these systems, the fluid is sprayed into a tank held at a much lower pressure than the fluid, causing some of the fluid to rapidly vaporize, or flash, to steam. The steam is used to drive a turbine, which again, drives a generator. Some liquid remains in the tank after the fluid is flashed to steam; if it's still hot enough, this remaining liquid can be flashed again in a second tank to extract even more energy for power generation.

Steam plants use very hot (more than 150° C)

steam and hot water resources (as found at The Geysers plants in northern

California - the largest geothermal electricity producer in the world).

The steam either comes directly from the resource, or the very hot, high-pressure

water is depressurized ("flashed") to produce steam. The steam then turns

turbines, which drive generators that generate electricity. The only significant

emission from these plants is steam (water vapor). Minute amounts of carbon

dioxide, nitric oxide, and sulfur are emitted, but almost 50 times less

than at traditional, fossil-fuel power plants. Energy produced this way

currently costs about 4-6 cents per kWh.

Binary plants use lower-temperature, but much

more common, hot water resources (40° C - 150° C). The hot water is passed

through a heat exchanger in conjunction with a secondary (hence, "binary

plant") fluid with a lower boiling point (usually a hydrocarbon such as

isobutane or isopentane). The secondary fluid vaporizes, which turns the

turbines, which drive the generators. The remaining secondary fluid is

simply recycled through the heat exchanger. The geothermal fluid is condensed

and returned to the reservoir. Because binary plants use a self-contained

cycle, nothing is emitted. Energy produced by binary plants currently costs

about 5 to 8 cents per kWh. Because these lower-temperature reservoirs

are far more common, binary plants are the more prevalent.

Moderate-temperature water

For water with temperatures less than 200

deg. C, binary cycle technology is generally most cost effective. In these

systems, the hot geothermal fluid vaporizes a secondary -or working - fluid,

which then drives a turbine and generator.

Steam resources are the easiest to use, but they are rare. The only steam field in the United States that is commercially developed, The Geysers, is located in Northern California. The Geysers began producing electricity in 1960. It was the first source of geothermal power in the country and is now the largest single source of geothermal power in the world.

Hot water plants, using high- or moderate-temperature geothermal fluids, are a relatively recent development. However, hot water resources are much more common than steam. Hot water plants are now the major source of geothermal power in both the United States and the world. In the United States, hot water plants are operating in California, Hawaii, Nevada, and Utah.

Geothermal

power plants in the Imperial Valley near Brawley, California

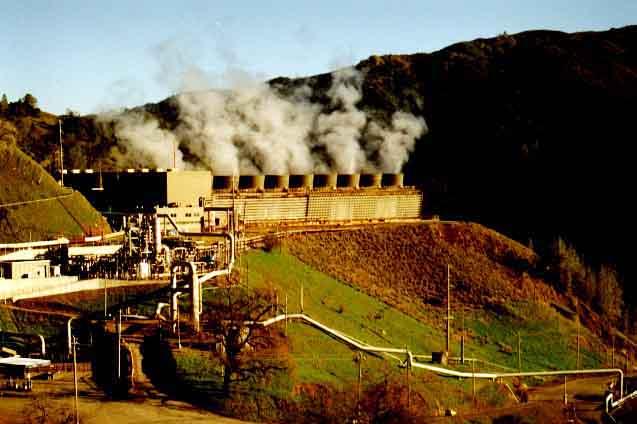

Geotermal power plant in Geysers, USA.

Geothermal power plants are very reliable when compared to conventional power plants. For example, new steam plants at The Geysers are operable more than 99% of the time. Taken as a group, geothermal power plants have system availabilities of 95% or higher, compared to 60%-70% for coal and nuclear plants. In addition, the capacity factor of geothermal power plants is highest among all types of power plants. Capacity factor is the amount of energy actually produced per year in kilowatt-hours (kWh) compared with the amount that could be produced if the plant operated continuously at full capacity.

After providing heat, the geothermal fluids are injected down wells back into the geothermal reservoir. This injected fluid replenishes the geothermal reservoir and maintains the pressure needed to continue producing hot water or steam.

FUTURE OF GEATHERMAL POWER

Hydrothermal reservoirs are not the only possible

source of geothermal electricity. Hot dry rock offers enormous potential

for electricity production. Hot dry rock energy comes from relatively water-free

hot rock found at various depths beneath the Earth's surface. One way to

extract the energy is by circulating water through man-made fractures in

the hot rock. Heat can be extracted from the water at the surface for power

generation, and the cooled water can then be recycled through the fractures

to pick up more heat, creating a closed-loop system. When technology is

developed to make hot dry rock resources commercially viable, they are

sufficiently large to supply a significant fraction of U.S. electric power

needs for centuries.

Geopressured brines - hot, pressurized, methane-rich waters found in sedimentary basins 3000 to 6000 meters below the surface-and magma-molten or partially molten rock within the Earth's crust-may also someday provide electricity. However, at this time, technology has not advanced to the point where geopressured brines and magma can be cost effectively exploited.

When hydrothermal reservoirs, hot dry rock, geopressured brines, and magma are considered together, the potential for electricity production from geothermal resources is very large. In general hydrothermal reservoirs, the only geothermal resources to date that can be economically extracted for electricity production, represent just one-tenth of that resource base. With advances in technology, geothermal resources have the potential to provide nearly limitless energy from the Earth.

ENVIRONMENT

In the past, when our environment was in a

healthier state than it is at present and we

were less aware of the threat to the earth,

geothermal energy was still considered a 'clean energy'. There is actually

no way of producing or transforming energy into a form that can be utilized

by man without making some direct or indirect impact on the environment.

Even the oldest and simplest form of producing thermal energy, burning

wood, has a detrimental effect, and deforestation. Similarly, exploitation

of geothermal energy also has an impact on the environment, although it

must be said that it is one of the least polluting forms.The geothermal

fluids are drawn from the Earth and returned to the Earth, so environmental

emissions are very low.

A typical geothermal plant requires several wells. Although drilling these wells has an impact on the land, the impact can be minimized by using advanced directional or slant drilling. This allows several wells to be drilled from one drilling pad, minimizing the amount of land needed for drilling pads, access roads, and geothermal fluid piping.

Sources of pollution

In most cases the degree to which geothermal

exploitation affects the environment is

proportional to the scale of such exploitation.

Electricity generation in binary cycle plants will affect the environment

in the same way as direct heat uses. The effects are potentially greater

in the case of conventional back-pressure or condensing power-plants, especially

as regards air quality, but can be kept within acceptable limits. Any modification

to our environment must be evaluated carefully, in deference to the relevant

laws and regulations, which in some countries are very severe, but also

because an apparently insignificant modification could trigger a chain

of events whose impact is difficult to fully assess beforehand.

For example, a mere 2-3 °C increase in the temperature of a body of water as a result of discharging the waste water from a utilization plant could damage its ecosystem. The plant and animal organisms that are most sensitive to temperature variations could gradually disappear, leaving a fish species without its food source. An increase in water temperature could impair development of the eggs of other fish species. If these fish are edible and provide the necessary support for a community of fishermen, then their disappearance could be critical for the community at large. The example we have just given is hypothetical but does not fall short of the truth.

The first perceptible effect on the environment is that of drilling, whether the boreholes are shallow ones for measuring the geothermal gradient in the pre-feasibility exploration phase, or exploratory/producing wells. Installation of a drilling rig and all the accessory equipment entails the construction of access roads and a drilling pad. The latter will cover an area ranging from 300-500 m2 for a small truck-mounted rig (max.depth 300-700 m) to 1200-1500 m2 for a small-to-medium rig (max. depth of 2000 m). These operations will modify the surface morphology of the area and could damage local plants and wildlife. Blowouts can pollute surface water; blowout preventers should be installed when drilling geothermal wells where high temperatures and pressures are anticipated .

During drilling or flowtests undesirable gases

may be discharged into the atmosphere. The impact on the environment caused

by drilling mostly ends once drilling is completed.

The next stage, installation of the pipelines

that will transport the geothermal fluids and

construction of the utilization plants, will

also affect animal and plant life and the surface

morphology. The scenic view will be modified,

although in some areas such as Larderello,

Italy, the network of pipelines criss-crossing

the countryside and the power-plant cooling

towers have become an integral part of the

panorama and are indeed a famous tourist

attraction.

Environmental problems also arise during plant operation. Geothermal fluids (steam or hot water) usually contain gases such as carbon dioxide (CO2), hydrogen sulphide (H2S), ammonia (NH3), methane (CH4), and trace amounts of other gases, as well as dissolved substances whose concentrations usually increase with temperature. For example, sodium chloride (NaCl), boron (B), arsenic (As) and mercury (Hg) are a source of pollution if discharged into the environment. Some geothermal fluids, such as those utilized for districtheating in Iceland, are freshwaters, but this is an exception to the rule. The waste waters from geothermal plants also have a higher temperature than the environment and therefore constitute a potential thermal pollutant.

Discharge of waste waters is also a potential

source of chemical pollution. Spent

geothermal fluids with high concentrations

of chemicals such as boron, fluoride or arsenic should be treated, re-injected

into the reservoir, or both. However, the low-to-moderate temperature geothermal

fluids used in most direct-use applications generally contain low levels

of chemicals and the discharge of spent geothermal fluids is seldom a major

problem. Some of these fluids can often be discharged into surface waters

after cooling. The waters can be cooled in special storage ponds or tanks

to avoid modifying the ecosystem of natural bodies of waters (rivers, lakes

and even the sea).

Extraction of large quantities of fluids from geothermal reservoirs may give rise to subsidence phenomena, i.e. a gradual sinking of the land surface. This is an irreversible phenomenon, but by no means catastrophic, as it is a slow process distributed over vast areas. Over a number of years the lowering of the land surface could reach detectable levels, in some cases of the order of a few tens of centimetres and even metres, and should be monitored systematically, as it could damage the stability of the geothermal buildings and any private homes in the neighbourhood. In many cases subsidence can be prevented or reduced by reinjecting the geothermal waste waters.

Although many geothermal plants generate no appreciable solid waste, the unique characteristics of some geothermal fluids require special attention to handle the solid by-products.At California's Salton Sea, a large geothermal reservoir went undeveloped for years because the geothermal water contains high amounts of dissolved corrosive salts. To solve this problem, industry developed a process for crystallizing the salts, which could then be separated from the water. The process was successful-eight power plants at the Salton Sea now supply 235 MW of power to southern California.

The solid by-product produced by these plants often contains just enough heavy metals to require special disposal. The plants produce as much as 45 kg of solids per megawatt-hour (MWh) of electricity generated, but recent technical advances are greatly reducing the amount requiring disposal. Some plants are now able to dewater the by-products and rinse them to remove the heavy metals. The rinse water is injected back into the reservoir, and the remaining solids-mostly silica-are used as filler in concretes for building roads and flood-protection levees.