| About Us | Contact Us | Contact Database | Support Us |

- MANUAL-

In this chapter various

sustainable energy technologies

are discussed, which are largely proved to have benefited the people.

Some of the technologies are

under experimentation. The technologies pertain mainly to cooking,

generation of electro-magnet energy and other devices.

3.1 Cooking Devices

In rural areas of South Asia, mainly biomass energy (fuel wood, agri-residue and animal dung) is used for cooking and heating purposes. Use of traditional stoves consumes more fuel wood increasing the burden on women, as women are mainly responsible for cooking and collection of biomass. Use of biomass energy and low-grade biomass fuels lead to excessive levels of indoor smoke/air pollution. Women and children in particular are exposed to the smoke emission. This is one of the reasons for higher rates of infant mortality and morbidity and other unhealthy living conditions. Release of carbon dioxide and other harmful gasses in the atmosphere due to poor combustion of biomass fuels in rudimentary stoves resulting into the emission of green house gases (GHGs). More than 80% of the energy needs are met by fuel wood thus exerting immense pressure on the forest resources with negative impacts on environment.

In order to reduce indoor air pollution and increase fuel efficiency as well as protect the forest resources and environment, several initiatives were taken up. As a result of considerable research and development various options are now available such as improved cook stove, biogas, charcoal and biomass briquetting, solar cookers and hay box cooker, etc. which are environmentally sustainable. Though there are advantages and limitations in each option, these are overcome by availability of several models for each technology for cooking purposes.

Although improved cook stove projects (ICPs) have been implemented in Asia since the 1950s, too many projects over long period of time have experienced consistently low adoption rates. This is primarily due to two reasons. One reason is the fact that technical cook stove expertise is still highly centralized. In any Asian country, Nepal and Indonesia are two which stand-out. There may be only one technical expert who is recognized as an improved cook stove designer. Other reason is the improved stoves introduced across a country are often limited to one or two designs. Trainings that have been held in the past have limited themselves to the design and construction of these one or two designs. These designs, although they may be appropriate to the needs, wants and conditions of one target group, will never be appropriate for all possible target groups. There are too many variables involved.

In answer to this problem the Asia Regional Cook stove Program (ARECOP) based in Yogyakarta, Indonesia and the FAO’s Regional Wood Energy Development Program (FAO-RWEDP) in Bangkok, Thailand embarked on a collaborative effort to implement Asia regional trainings to decentralize ICP technical skills and programmatic knowledge. This training is different from those before it. It is not designed to transfer particular stove designs or stove building techniques. It invites participants to use a process of selecting a stove and dissemination pattern that does not ignore the multitude of variables which are connected to any stove. These variables include fuels commonly used, available stove materials and their characteristics, economic limitations, gender roles, kitchen size and layout, preferred cooking position, cooking habits, foods commonly cooked, traditions, household industries, non-cooking functions of stoves, combustion theory, heat transfer and heat loss theory.

The training is aimed at improved stove project field workers who are involved in the initial surveys and assessment activities and have the most information to make wise choices in modifying the traditional stove or selecting another improved stove design. The process used cannot be defined as technical or non-technical. It is both, as both must be integrated in the development of an appropriate stove design.

3.1.1 Stoves

In different areas of South Asia, different types of improved cook stoves are developed which have their own merits and demerits but are popular as these are suitable to particular area. While the most popular stoves from Sri Lanka and Nepal are described as below.

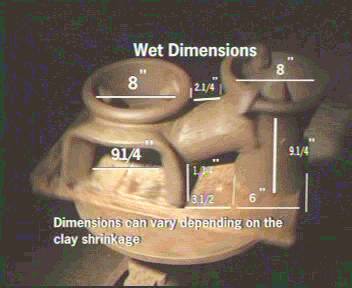

3.1.1.1 “Anagi” Stove Construction in Sri Lanka

The most popular ICS in Sri Lanka is marketed under the trade name “Anagi”. Word “Anagi” in Sinhala language means ‘preciouses or ‘excellent’. So “Anagi” stove is an excellent and precious stove because it saves firewood and cooking time provided it is made to the correct dimensions. Lab tests carried out on the stove spell the technical efficiency of 21%, and numerous field-cooking tests tell average firewood savings to be over 30%, twice as good as traditional stoves.

Anagi is two pot single piece clay stove designed to meet the cooking

needs of a family of 6 people. It can accommodate medium size hard or

soft wood and other loose biomass residues such as coconut shells, fronds

and leaves.

Anagi is two pot single piece clay stove designed to meet the cooking

needs of a family of 6 people. It can accommodate medium size hard or

soft wood and other loose biomass residues such as coconut shells, fronds

and leaves.

The stove design has been carefully developed to suit the

cooking habits and the types of food cooked in Sri Lanka. The stove can

be used directly, which is preferred for short cooking as done in urban

houses. For cooking over a long period of time as in many rural houses,

insulating the stove with a mud mixture improves the firewood saving

capability. The lifetime of the stove may be about 3 years instead of

1 year if used directly without any insulation.

Anagi stove has three main components: (i) Fire box, (ii) 2nd pot hole, and (iii) Tunnel (which connects the firebox and the 2nd pot seat). Likewise, secondary components are: (i) pot rests, (ii) buttresses, (iii) baffle, (iv) flame shield, and (v) the door.

Anagi was first introduced in 1986 by the Ceylon Electricity Board in

collaboration with the ITDG under the Urban Stoves Programme. Its success

prompted the stove to be selected for commercialization in the rural

areas with the participation of the Integrated Development Association

(IDEA) and the ITDG. Later, the Asian Cook stove Programme (ARECOP) supported

the programme, which got success in installing 300,000 stoves in remote

villages.

3.1.1.2 Improved Cook Stove in India

The National Programme on Improved Chulha (NPIC) was started in 1986-87 by Govt. of India as a programme for women, by women & through women with the following objectives:

- Conservation of fuel wood and other biomass.

- Removal of smoke from kitchen.

- Check on deforestation and environmental up gradation.

- Reduction in the drudgery of women and girl children from cooking in smoky kitchen.

- Reduction of health hazards and in cooking time.

- Provides employment opportunities to rural people.

Cumulative Achievement:

-

Over 350 Lakh (35 million) Improved Chulhas (as against estimated the total potential of 1200 Lakh or 120 million) up to March 2003 have been installed in various states of India.

-

NPIC is implemented with a multi-agency approach.

-

"Self Employed Workers", mainly women, from Rural & Semi urban area are twist-trained hands on who are providing service for the proper construction and maintenance of the fixed type chulhas.

-

More than 30 models of durable fixed with chimney and portable improved chulhas are available for family, community and commercial applications.

-

There are fifteen manufacturers of ISI marked portable metallic chulhas in the country.

In India several models have been developed and promoted, out of which two models are presented here:

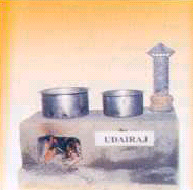

Udairaj:

Udairaj

cook stove is a double pot design suitable for burning firewood, dry

dung cakes, crop residues and other traditional fuels. Stove is suitable

for roasting chapatti in open combustion chamber. On the rear of the

space for the two cooking pots a chimney has been provided to let off

the smoke and products of combustion. The stove is meant for using both

the fire pots simultaneously. Construction is of good quality bricks

and cement mortar. Additional mud insulation is provided on the exteriors

of the stove to reduce skin bum on contact.

Laxmi:

This chulha accepts two pots at a time. It is also provided with a chimney.

There are no pot raisers, and because the pots sit flush on the potholes,

the flue gases do not escape into the kitchen, but are taken out of the

house.

Out of the total heat generated by the fuel, about 60% is available

at the first pothole and 40% at the second pothole. It is thus possible

to cook food simultaneously on both the potholes. The disadvantage of

a two-pot chulha is that a part of the heat is wasted if the second pothole

is not used.

3.1.1.3 Improved Cook Stove– CRT Nepal

The type of Improved Cook Stove (ICS) promoted in Nepal is made up of 3-part mud/earth, 2 parts straw/husk and 1 part animal dung. The whole structure is plastered smooth with the same mud mortar. ICS has two fire openings for cooking pots, one behind the other.

There is no need to blow the fire. It utilizes the heat, generated by

burning fuel wood, more by the deflection of the flames and heated air

inside it which travel to the second opening with the help of an in-built

baffle located just below the second opening, before the hot air exits

out of the chimney, which is made of un-burnt clay bricks that can be

made in the village. The iron plates are fitted on the potholes for pots.

The potholes are round in shape; the pot bottom fits tight on them. It

can be made in different sizes and capacities to suit the family size

and pot size. It can have one or more openings for pots/pans.

ICS can even be used for space heating by adding a cast iron/mild steel

plate put tight over the pot holes for the pots or by putting a metal

pipe around the space/room to make the pots or by putting a metal pipe

around the space/room to make the hot air pass around the room through

the pipe before going out through the chimney. Nowadays, use of ICS for

water heating by attaching a back boiler on the side or around the chimney

pipe is increasing in the mid-hills and mountain regions of Nepal. The

materials required for the construction of ICS are locally available

and includes stones/bricks, mud/earth, straw/rice husk, iron plates/

rebar/sheet, animal dung. In addition to the domestic institutional improved

cook stoves (ICS), promotion of institutional ICS is being carried out

in hotels, teashops, schools, hostels, and barracks.

ICS can even be used for space heating by adding a cast iron/mild steel

plate put tight over the pot holes for the pots or by putting a metal

pipe around the space/room to make the pots or by putting a metal pipe

around the space/room to make the hot air pass around the room through

the pipe before going out through the chimney. Nowadays, use of ICS for

water heating by attaching a back boiler on the side or around the chimney

pipe is increasing in the mid-hills and mountain regions of Nepal. The

materials required for the construction of ICS are locally available

and includes stones/bricks, mud/earth, straw/rice husk, iron plates/

rebar/sheet, animal dung. In addition to the domestic institutional improved

cook stoves (ICS), promotion of institutional ICS is being carried out

in hotels, teashops, schools, hostels, and barracks.

The materials required for the ICS construction are locally available and the users have to bear the cost of iron rod and installation charge only. The cost varies depending upon the place but in general it is approximately 300-400 Nepali rupees.

Problems and Solutions:

ICS is a simple technology based on scientific concept and easy to operate. Users do not face any severe technical problems during its operation. The problems may arise when ICS Promoters do not adhere to the technical specification during installation and due to negligence of users during regular maintenance.

The development of mud brick stove by Research Center for Applied Science

and Technology, Nepal (RECAST) in early nineties, which could be built

on site in users households, by trained self employed workers (Promoters)

with locally available materials gave the stove program a new look. The

collective efforts of over 25 such organizations together promoted about

40,000 improved stoves of various types (mud, metallic) in different

districts of Nepal.

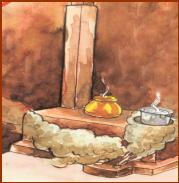

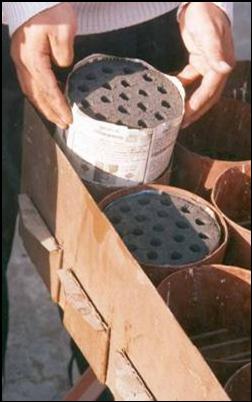

3.1.1.4 Stoves for Using Honeycomb/Beehive Briquettes

For burning honeycomb/ beehive biomass briquettes specially designed stoves are required, which could either be made of metal or clay. In India normally metal stove with provision of using two honeycomb/beehive briquettes are used as shown in pictures.

In Nepal both metal stoves as well as clay stoves are used, as can accommodate

one briquette of ½ kg inside the combustion chamber of the stoves.

The two models of biomass briquettes stoves, one made of metal and

the second one of clay, are designed specifically to burn single honeycomb/

beehive briquettes at a time. Because charcoal is frequently used for

barbeques and by restaurants requiring large heat capacity for cooking

or grills, in Nepal a metal barbeque stand has been developed in which

up to 8 honeycomb/ beehive biomass briquettes could be placed. Ventilation

holes are provided in the bottom, through which the briquettes could

be fired.

List of production items used in Nepal for making biomass honeycomb/beehive briquettes and the estimated cost in Nepalese Rupee (NR) and equivalent Indian Rupee (INR) are given in Table.3.1.

Items required for production and utilisation of biomass

honeycomb/ beehive briquettes |

Specifications |

Nepalese Rupees (NR) |

Indian Rupees (INR) |

Weed harvesting tools |

Axes, hoes |

300 |

180 |

Charring drum, 200 litre |

3 mm sheet metal,

4 pieces |

12,000 |

7,200 |

Grinder |

Metal, rotating |

10,000 |

6,000 |

Dust masks |

Cotton/cloth filters |

150 |

96 |

Mould, 19 pins, three piece |

5" diameter and 4" high |

5,000 |

3,000 |

Barbeque |

8 briquettes |

4,000 |

2,400 |

Thongs for briquettes |

To fit into holes |

30 |

18 |

Thick metal stove |

One briquette, lined |

400 |

240 |

Thin metal stove |

One briquette, lined |

300 |

180 |

Clay stove, three

piece |

One briquette, double wall |

400 |

240 |

Tibetan stove |

3 Briquettes, double wall |

300 |

180 |

Briquettes, hand compacted |

½ kg with

Banmara |

5 |

3 |

Compacting machine |

1000 kg, pedal operated |

25,000 |

15,000 |

Briquettes, press compacted |

0,6 kg with Banmara |

10 |

6 |

Transport container |

To be designed |

- |

- |

Note: 1 NR = 0.6 INR

Based on the feedback, brief information about the promotional aspects

of beehive briquettes stoves, in Nepal and India, as well as the comparative

observations are summarized below:

- The honey comb briquettes are round with about 5" (12.5 cm) diameter and 3" (7.5 cm) height.

- The stove is locally manufactured by small-scale metal workshops or local blacksmiths commonly using recycled sheet steel.

- The Nepali stove allows only one briquette whereas the Indian stoves have provision for burning two briquettes at a time.

- When used for cooking, if stove doesn’t have a fire shield around pot, cooking efficiency goes down.

- If the corners of briquettes get crumbles during handling, it will be due to higher percentage of soil in the briquettes, as well as insufficient compacting/ binding during production.

- High soil content, it results in producing large quantities of ashes while burning the briquettes.

Simple or clear information about the briquette and the briquette stoves

are required, backed by the awareness, motivation and education of the

end users to ensure wider acceptance of honeycomb briquettes in rural

areas of the country.